Technique for improving capability of removing CO with supported nano-Au catalyst normal temperature oxidization

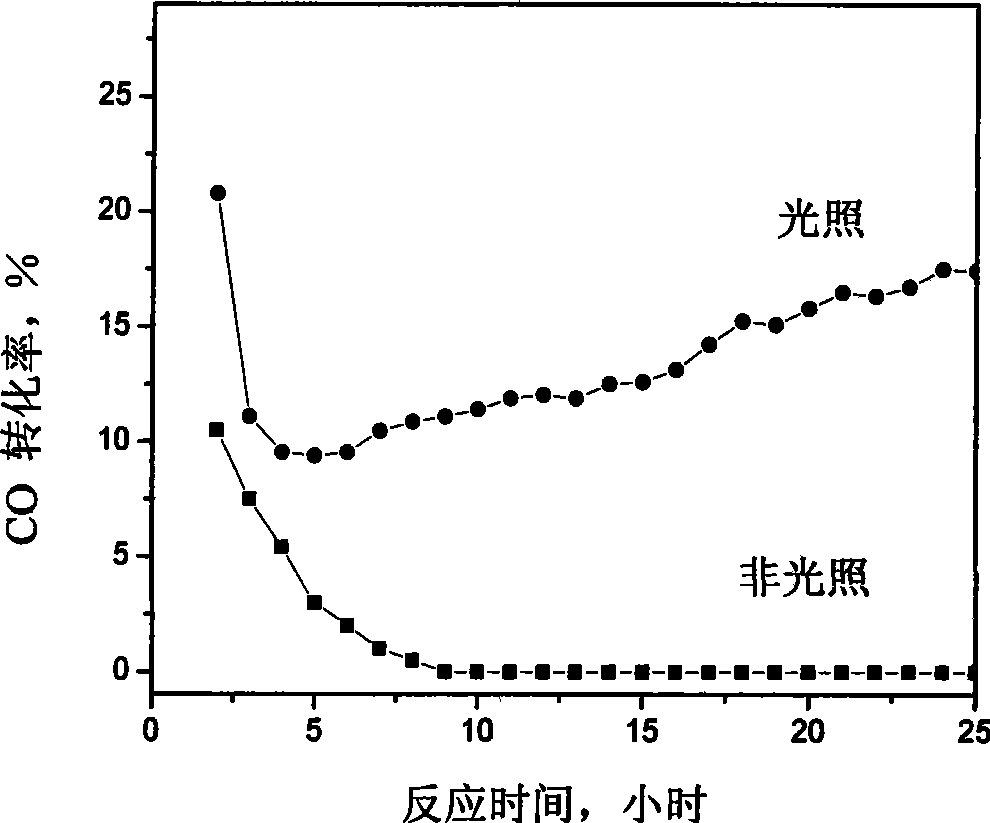

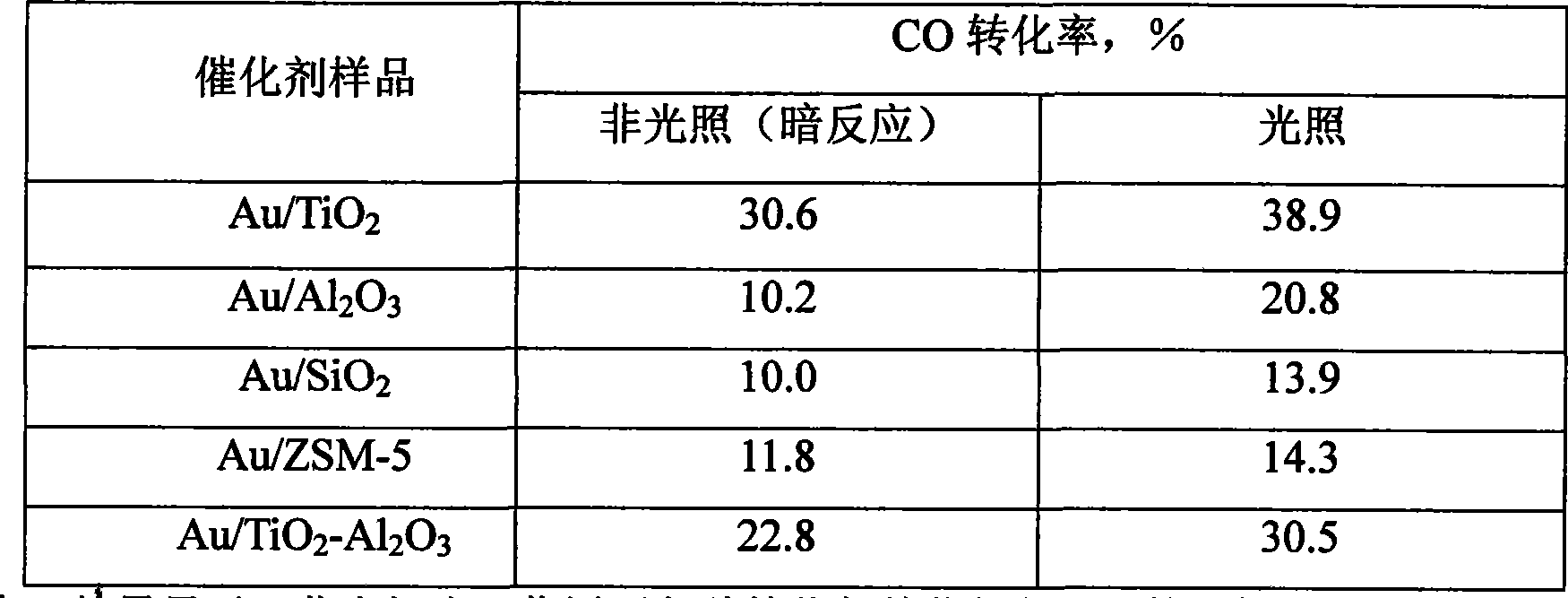

A technology of room temperature oxidation and catalytic oxidation, applied in molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problems of poor activity stability, etc., to improve performance, improve activity and Stability, the effect that is conducive to large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Au / TiO 2 Catalyst preparation

[0019] Weigh 1 gram of TiO 2 Powder (P25, particle size is 50-70 mesh), add it to 100ml of HAuCl with gold content of 0.01g / ml 4 In the solution (the solution was adjusted to pH about 9 with 1mol / L NaOH solution in advance), heat to maintain the temperature at 70°C, continue to add 1mol / L NaOH solution dropwise, control the pH of the suspension to 9, stir for 2 hours, then age for 2 hours, and filter to obtain solid powder . With 1mol / LNaBH 4 solution to reduce the powder, and then centrifuged with deionized water to remove Cl - 、Na + , dried at 80°C to prepare the supported nano-Au catalyst (Au / TiO 2 ). The content of Au in the catalyst is about 2.0 wt%.

Embodiment 2

[0021] Au / SiO 2 Catalyst preparation

[0022] Weigh 1 gram of SiO 2 (particle size is 50-70 mesh), according to the same method in embodiment 1, makes Au / SiO 2 catalyst. The content of Au in the catalyst is about 2.0 wt%.

Embodiment 3

[0024] Au / Al 2 o 3 Catalyst preparation

[0025] Weigh 1 gram of γ-Al 2 o 3 (particle size is 50-70 order), according to the same method in embodiment 1, makes Au / Al 2 o 3 catalyst. The content of Au in the catalyst is about 2.0 wt%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com