Voltage dependent resistor dielectric material of zinc oxide and method of manufacturing electrical resistor

A varistor, dielectric material technology, applied in varistor cores, varistors, coating resistance materials, etc., can solve the problems of low voltage, leakage current, high nonlinear coefficient and stability. In order to balance each other, it is difficult to meet the requirements of low voltage, high nonlinear coefficient, and low voltage sensitive voltage performance, etc., to achieve the effect of low cost, stable varistor characteristics, and low varistor voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples.

[0035] Table 1: Formulation Table of Embodiment 1

[0036] components ZnO Bi 2 o 3 TiO 2 Sb 2 o 3 MnCO 3 co 2 o 3 Cr 2 o 3 ZrO 2 Ni 2 o 3 SiO 2 content(%) 85 5 1.8 1.5 1.5 1.8 0.5 0.4 0.5 2.0

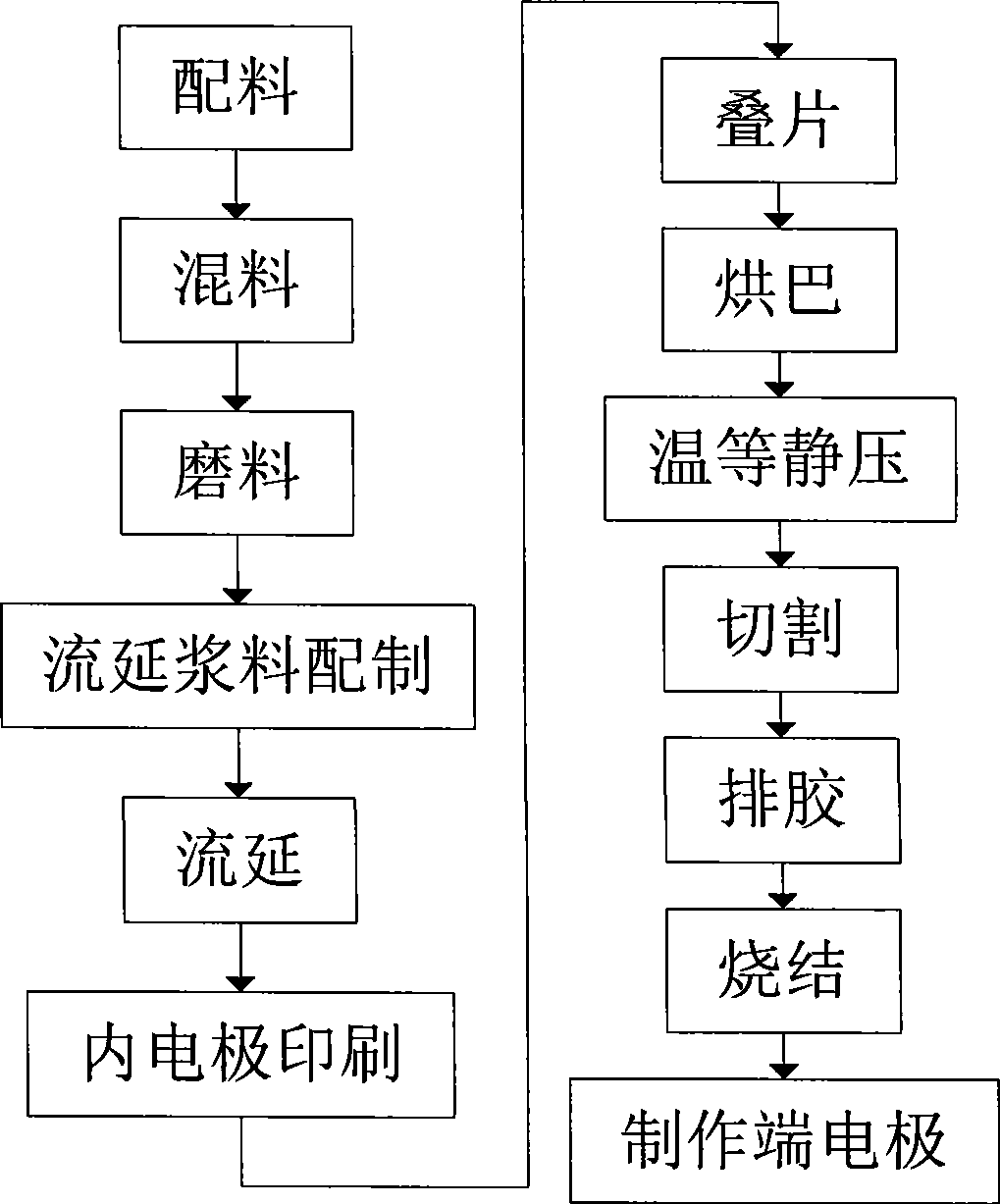

[0037] According to the formula in Table 1, such as figure 2 The manufacturing process shown in the flow chart prepares a chip zinc oxide varistor. The varistor voltage of the chip varistor is measured to be 5.6V (thickness of the film green body is 20 microns), the nonlinear coefficient is 52, and the leakage current is less than 1.0 microampere (measured at 80% varistor voltage).

[0038] It should be noted that: 1. The drying temperature in steps 2, 3, 6 and 8 is 120-130°C; 2. The pre-shrinkage sintering process conditions in step 2 are: heating rate 6-10°C / min, sintering temperature 840°C, holding time 2 hours; 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com