Imidazoline derivant, method of preparing the same, and uses of the same as gas-liquid diphasic inhibitor

A technology of imidazoline derivatives and derivatives, applied in the direction of organic chemistry, etc., to achieve the effects of simple operation, high corrosion inhibition efficiency and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

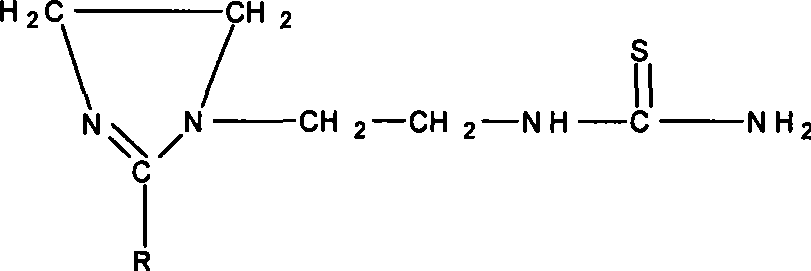

[0010] The imidazoline derivatives of the present invention are synthesized according to the following two steps, the first step:

[0011]

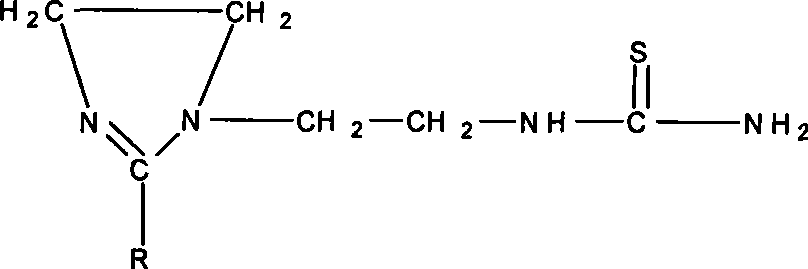

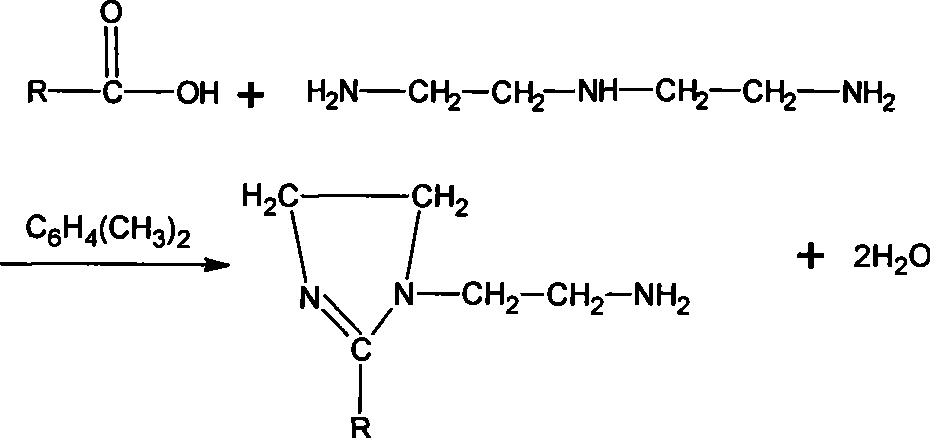

[0012] Step two:

[0013]

[0014] In the formula, R is a C7 to C16 alkyl group.

[0015] The corrosion inhibitor of the present invention is mainly composed of the above-mentioned compounds, but no purification is required. When the mixture obtained during the preparation is used as the gas-liquid two-phase corrosion inhibitor for the experiment, Q235 carbon steel is used as the sample, and the specification is 50mm×10mm×3mm. The carbon steel used is polished, rinsed with tap water, rinsed with alcohol, and dried with cold air according to the usual practice, and then placed in a desiccator equipped with silica gel desiccant for 24 hours before use. The experimental medium is an aqueous solution of NaCl filled with saturated carbon dioxide, airtight, the temperature is 40-80°C, and the test period is 72 hours. The experiment ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com