LED flexible neon lamp

A neon light and flexible technology, which is applied in the direction of damage prevention measures of lighting devices, lighting devices, light sources, etc., can solve the problems of inconvenient installation and use, large power line tension, and large external dimensions, and achieve convenient installation, large lighting angle, Small form factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

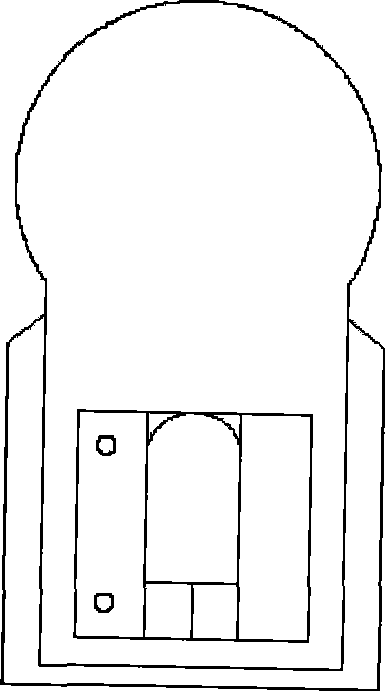

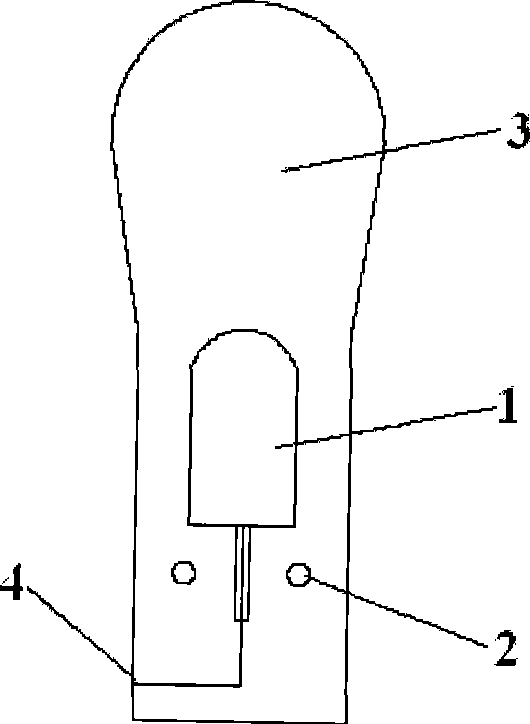

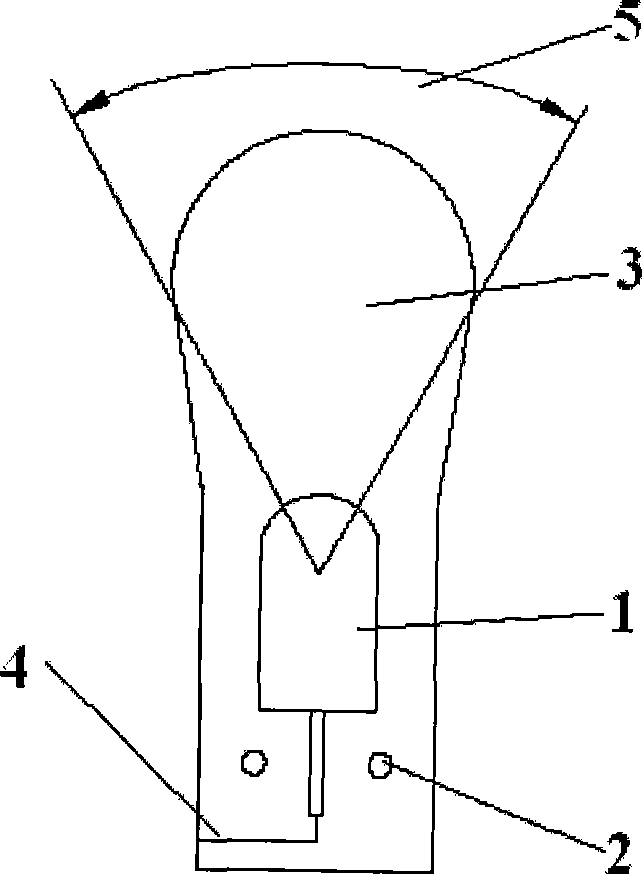

[0037] The above-mentioned LED illuminant 1 has a lateral luminous angle 6 of 70° and above 70°, and a longitudinal luminous angle 5 of 90° or less; It is upright and flat or patch-shaped.

[0038] The optimum value of the above-mentioned light-emitting angle is: the horizontal light-emitting angle is 110°; the vertical light-emitting angle is 60°.

[0039] The above-mentioned setting of the light emitting angle of the LED illuminant 1 can obtain the best effects of light emission, light mixing and light uniformity.

Embodiment 2

[0041] The material of the refraction light-transmitting tube body 3 described in the present invention is colored or colorless or a flexible colloid of the same color as LED light, and any one of light scattering agent, light guide powder, and phosphor powder, or any few of them, are added inside. combination of species.

[0042] The material of the above-mentioned refraction light-transmitting tube body 3 can also be a composite material of PE and PVC with different refractive indices, which is light-transmitting milky white, or the same color as the illuminant; spraying on its inner surface or outer surface or inside and outside The surface is sprayed with astigmatism agent titanium dioxide, or fluorescent powder, or acrylic powder, or fine glass beads, or any combination of the above materials, or other additives with astigmatism effect; Film 10.

[0043] Use PE or PVC with different outer skin refractive index with curved special-shaped tube, add astigmatism and laser ag...

Embodiment 3

[0045] The outer surface of the refraction light-transmitting tube body 3 at the bottom of the LED illuminant 1 described in the present invention is coated with reflective ink. Or install additional track tracks to fix, and block excess light, making it similar to the luminous effect of traditional neon lights.

[0046] The function of the reflective ink is to deflect excess light back and try to emit light from above to improve the overall luminous effect of LED flexible neon lights. For the beauty of the product, reflective ink can be coated on the side and bottom of the product, so that the light can only be emitted from the top.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap