Giant stamp forging hydraulic press upright post stress harvester and stress monitoring system

A collection device and monitoring system technology, applied in the field of a giant die forging hydraulic press column stress collection device and a stress monitoring system, can solve the problems of poor anti-interference ability of analog signals, inaccurate collected signals, harsh working environment, etc., so as to improve the anti-interference ability. Capability and reliability, improved safety, longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

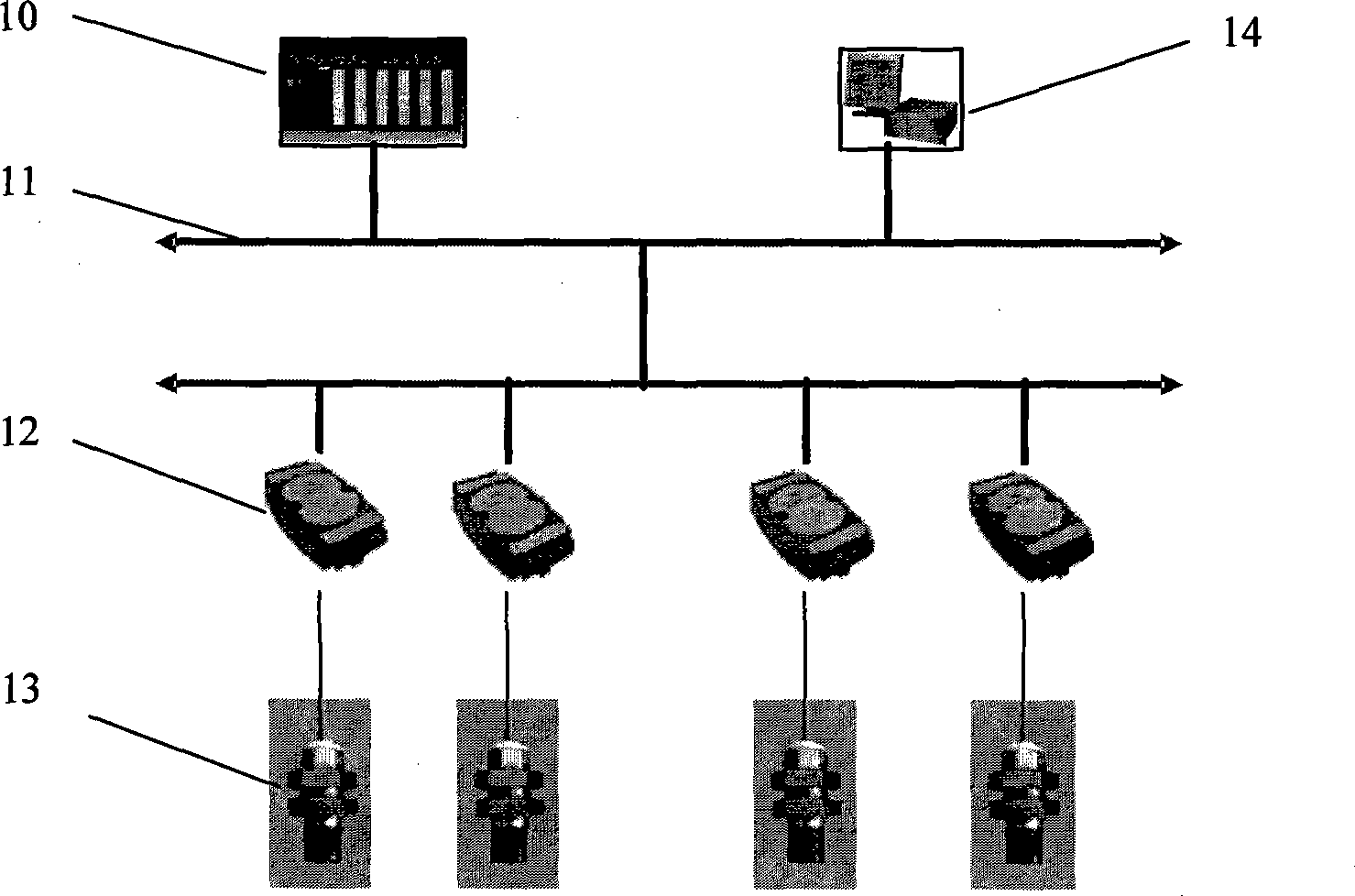

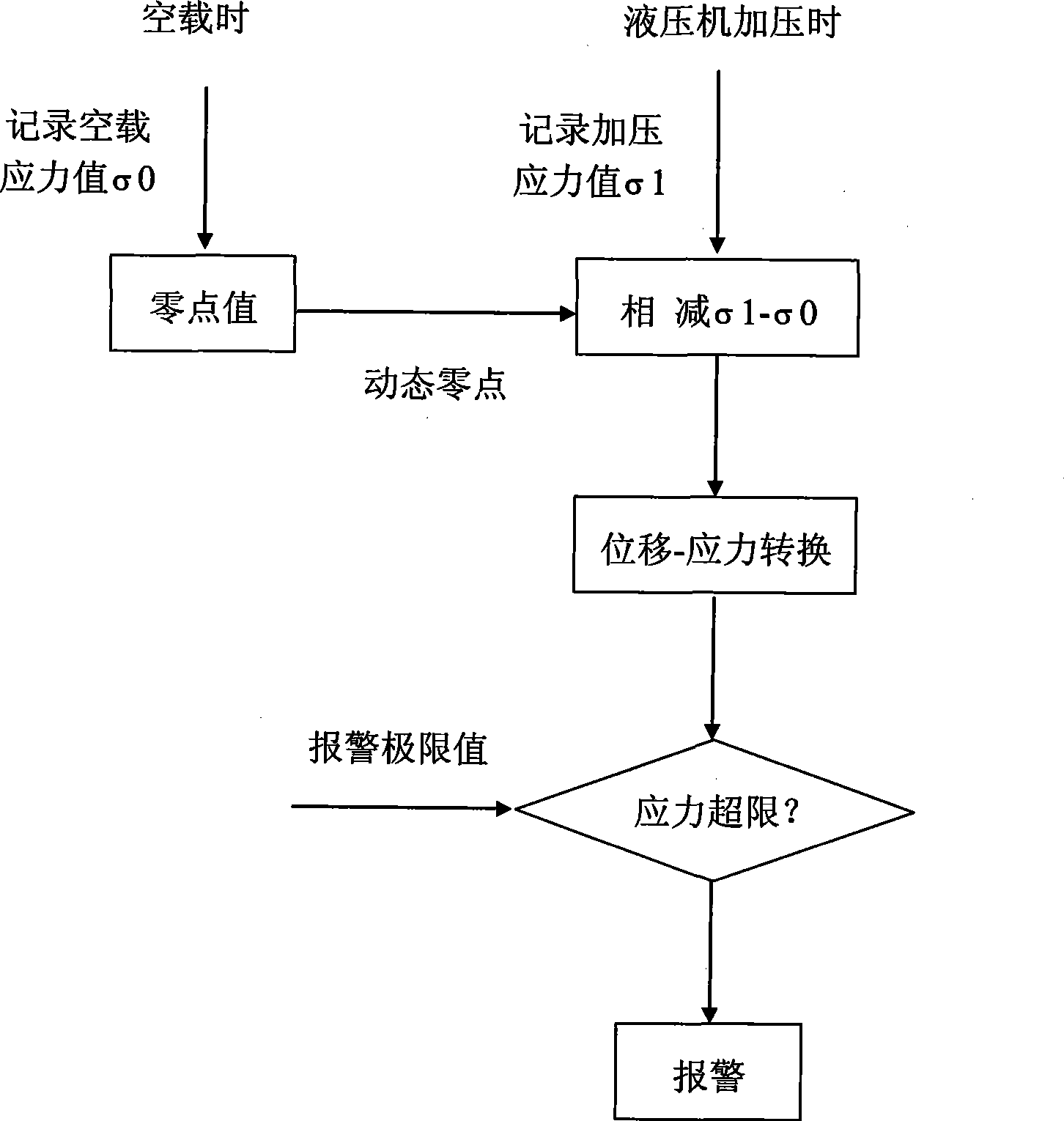

[0027] The column stress monitoring system of the giant die forging hydraulic press includes high-precision displacement sensors and mounting brackets, bus conversion modules (ie, analog-to-digital converters), PLC systems, and host computer monitoring systems. The technical scheme is as follows: measure the micro-displacement of the column in a non-contact way, convert the analog signal into a digital signal through an analog-to-digital converter (bus conversion module), realize full-digital data communication through an industrial field bus, and analyze and record stress data by a computer monitoring system , Generate stress monitoring data reports.

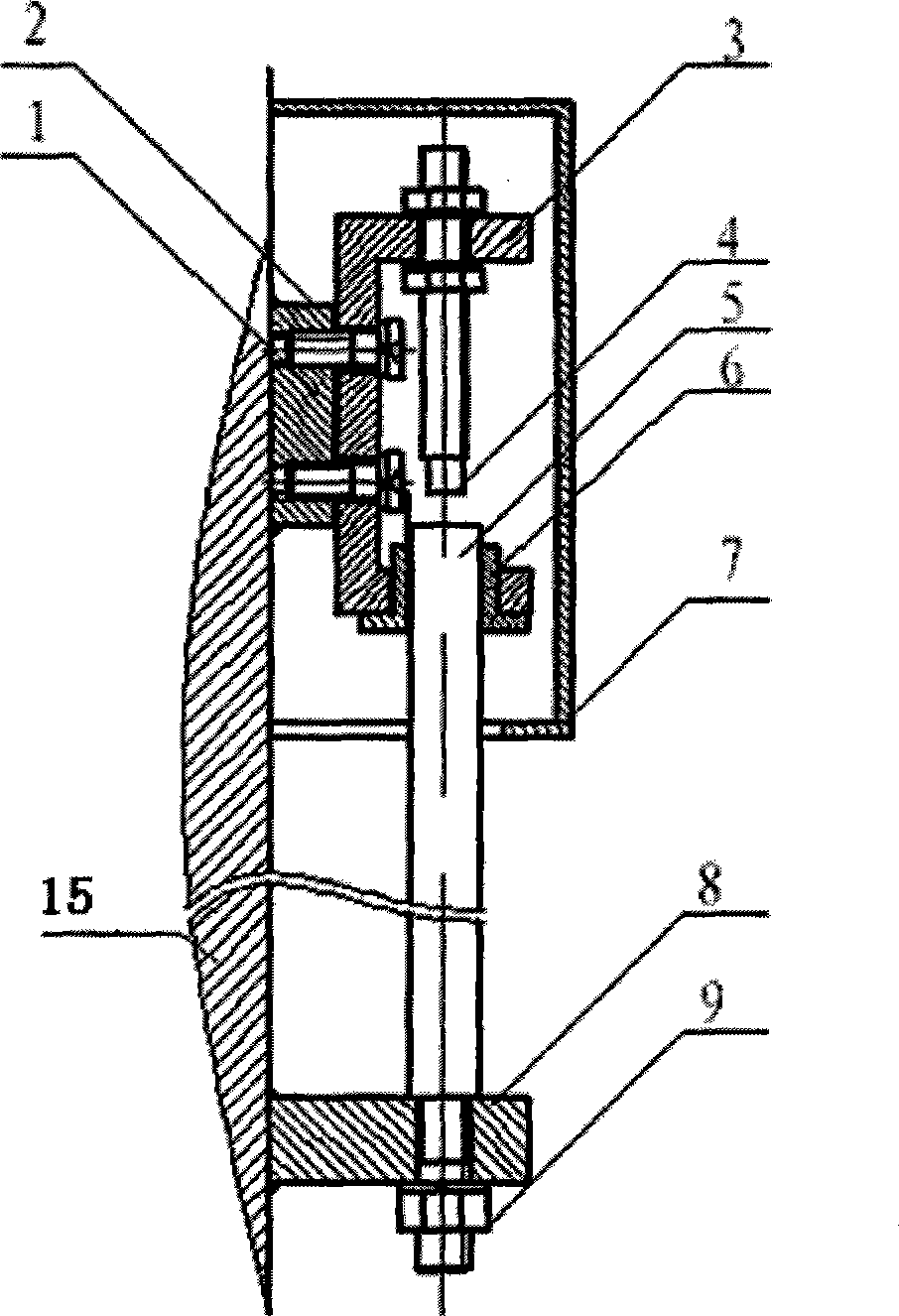

[0028] figure 1 The structure of the sensor mounting bracket of this embodiment is described. It is characterized by non-contact measurement. In the mounting bracket, the upper positioning block 1 and the lower positioning block 8 are welded to the surface of the column 15 of the hydraulic press. When the hydraulic press is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com