Anti-rust rust-removing method for water pipeline and anti-rust rust-removing apparatus

A technology for water delivery pipes and pipes, applied in the field of anti-rust and rust-removing devices, can solve the problems of negative impact on human health, rust scale does not work, need to continuously invest in medicines, etc., achieves good rust removal effect, reduces scale generation, The effect of rust removal and rust inhibition is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

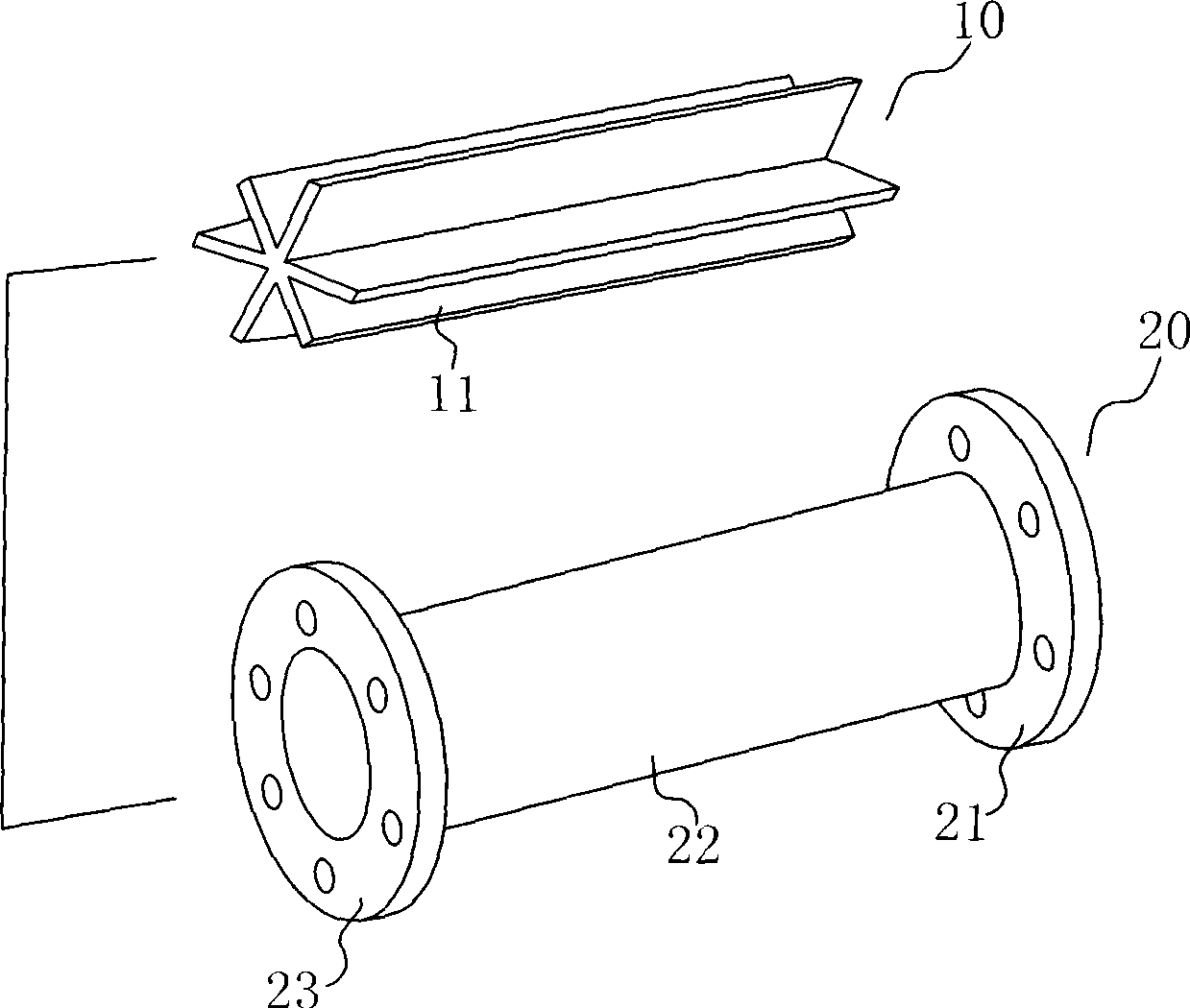

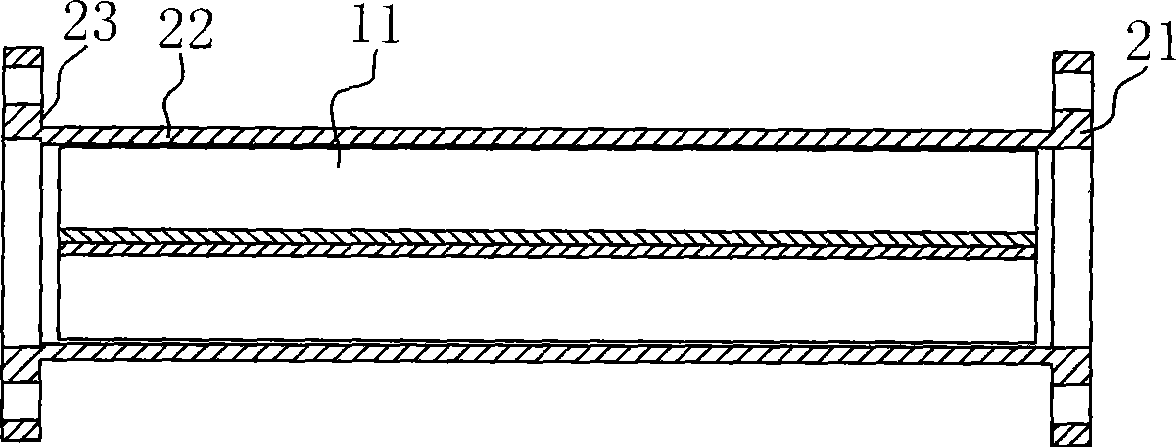

[0023] Example 1 The rust prevention and rust removal method of the water pipeline is to insert an outer pipe body on the water pipeline as a cathode, the two ends of the outer pipe body are connected to the water pipeline through flanges, and a water contact is set in the outer pipe body. The metal inner core is used as an anode, and the water flow in the water pipeline fully contacts with the metal inner core set in the outer tube body. The potential difference between the anode and the cathode reduces the binding force between the rust in the water pipeline and the inner wall of the pipeline, and sacrifices the anode to soften the water quality, so as to realize the function of rust prevention and pipeline protection. The outer pipe body is made of copper alloy, and the metal inner core set in the outer pipe body is made of magnesium alloy, and the two ends of the outer pipe body are connected with the water pipeline through flanges.

[0024] The metal inner core is a colum...

Embodiment 2

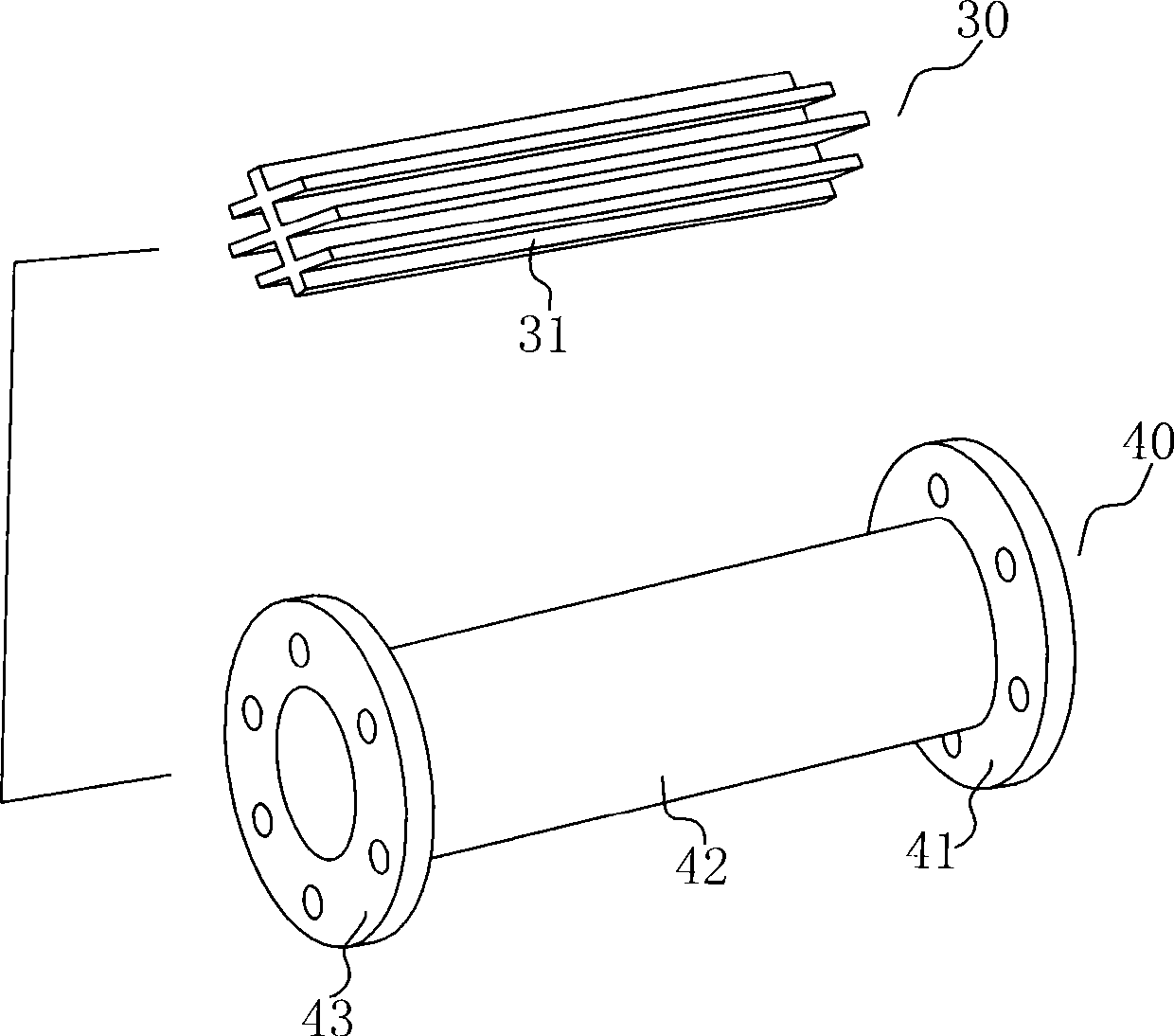

[0026] Embodiment 2 The rust prevention and rust removal method of the water delivery pipeline is to connect an outer pipe body on the water delivery pipeline as a cathode, the two ends of the outer pipe body are connected to the water delivery pipeline through flanges, and a water contact is set in the outer pipe body. The metal inner core is used as an anode, and the water flow in the water pipeline fully contacts with the metal inner core set in the outer tube body. The potential difference between the anode and the cathode reduces the binding force between the rust in the water pipeline and the inner wall of the pipeline, and sacrifices the anode to soften the water quality, so as to realize the function of rust prevention and pipeline protection. The outer pipe body is made of copper alloy, and the metal inner core set in the outer pipe body is made of magnesium alloy, and the two ends of the outer pipe body are connected with the water pipeline through flanges.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com