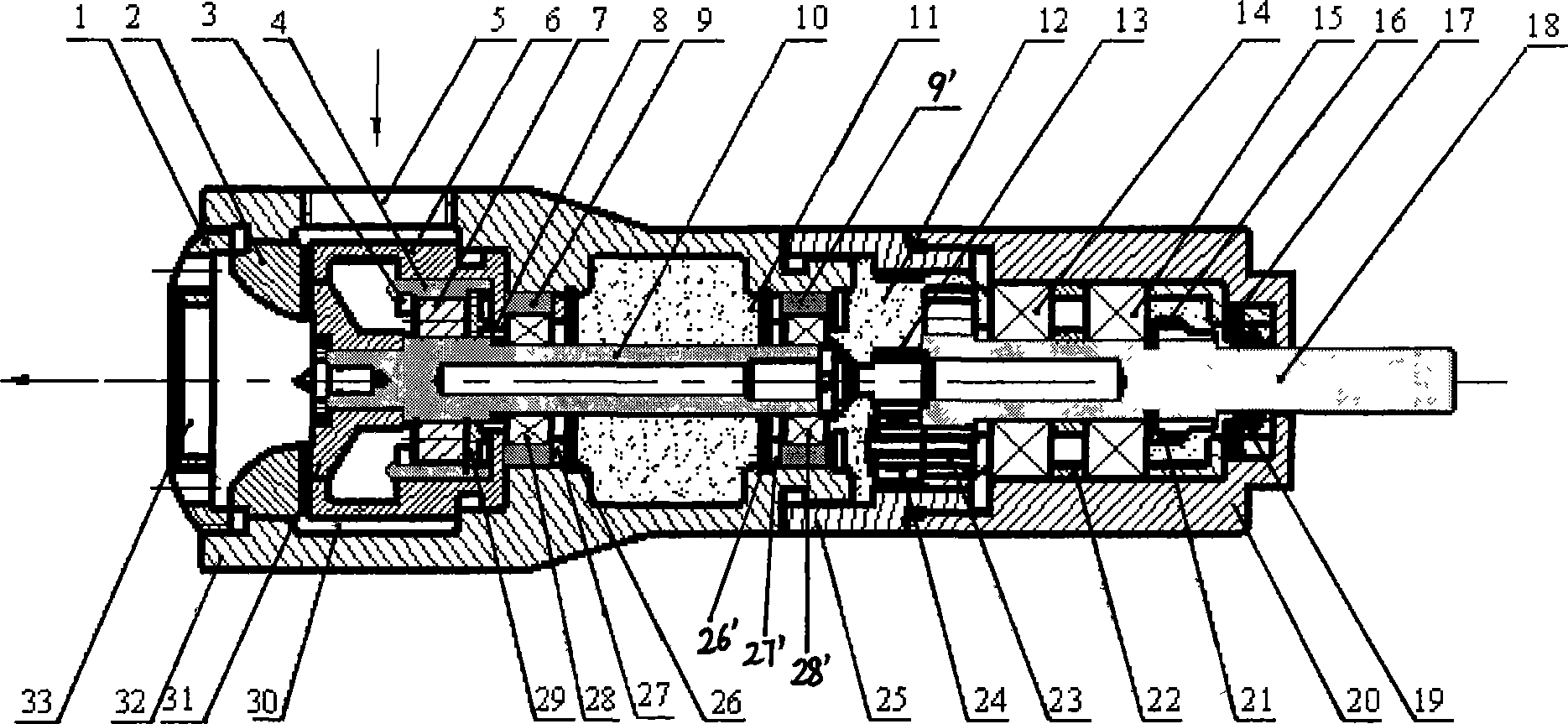

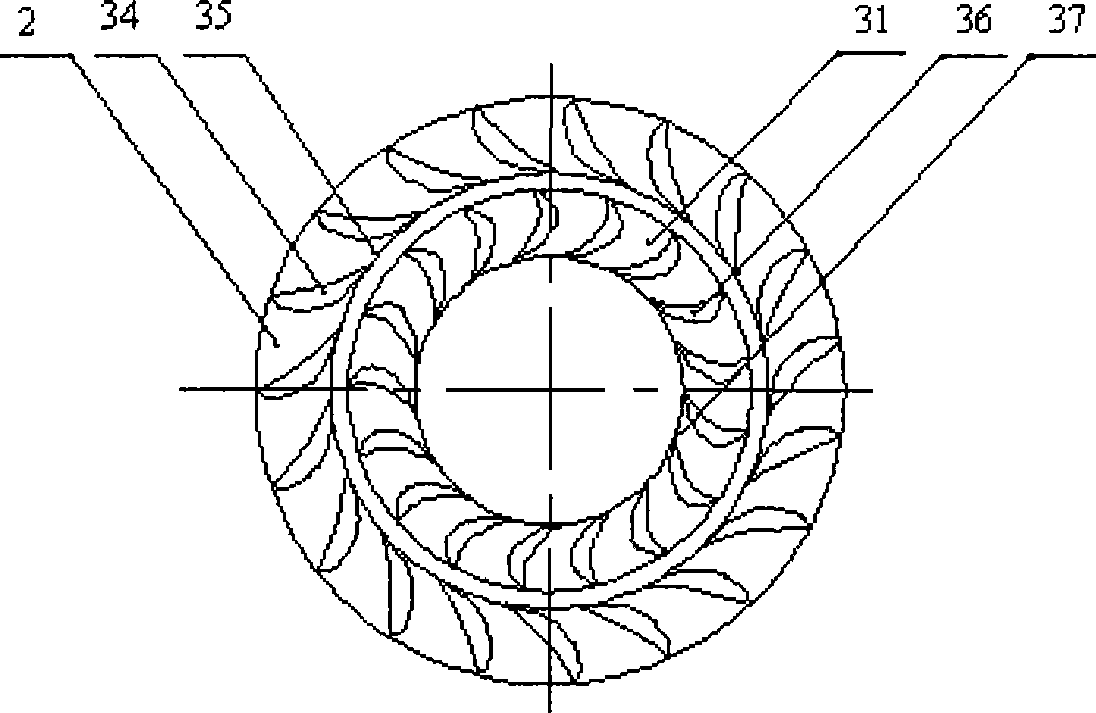

Turbine pneumatic motor

A turbo-pneumatic and motor technology, used in engine components, machines/engines, non-variable-capacity engines, etc., can solve the problems of poor energy utilization, high working pressure, and low efficiency, and achieve high energy utilization and work. Low pressure, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] From the perspective of energy conversion, the counterattack turbine air motor of the present invention converts the available enthalpy drop of the gas working medium into mechanical energy, which is different from the volumetric air motor which mainly converts the pressure energy of the gas working medium into mechanical energy. From a structural point of view, the air motor of the present invention not only contains counterattack micro-turbines and planetary gear reduction mechanisms, but also has no sliding contact between parts between the turbine stator and the rotor. The principle differences and structural features of the above energy utilization methods make the counterattack turbine air motor of the present invention not only have the advantages of compact structure, long working life, easy maintenance and no need for internal lubricating oil for the gas working medium, but also have high energy utilization rate. , high efficiency (up to 65%), low working pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com