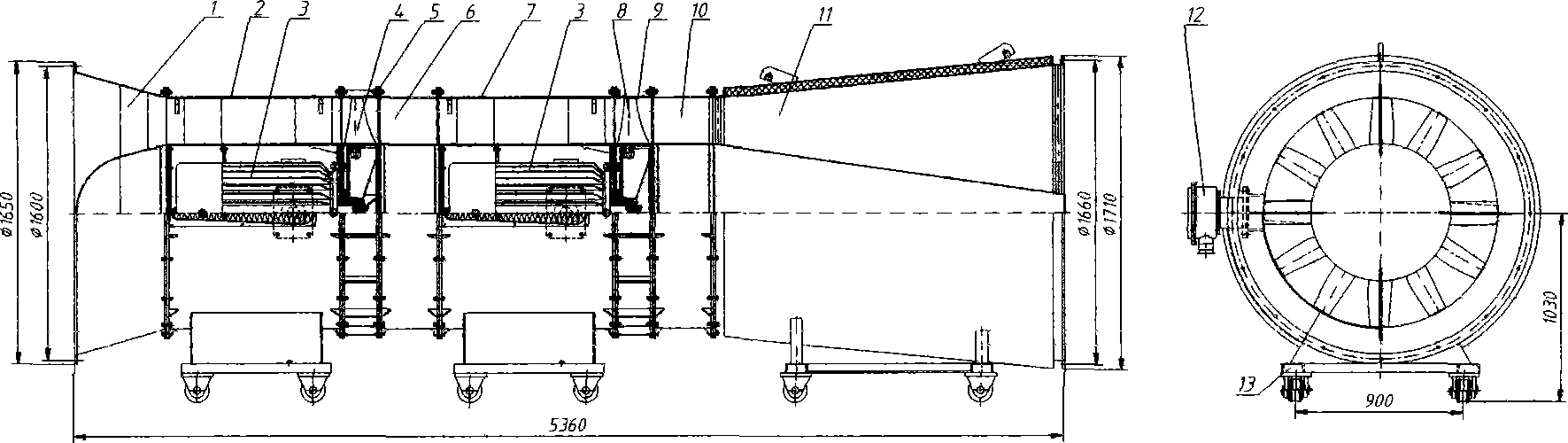

Drive tandem explosion-proof fan with two built-in electric motors

A dual-motor and fan technology, applied in the direction of machines/engines, pump devices, mechanical equipment, etc., can solve the problems of long blade use, low operating efficiency, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Since the motor is built into the fan casing, the connection between the motor and the fan impeller has been adjusted by the manufacturer according to the technical requirements before installation, and the fan only needs to be installed according to the requirements during installation. It can be placed on the pre-laid installation track, and the whole ventilator can be placed outdoors directly, without the need to build a special ventilator room. The installation is very convenient, saving time and space.

[0013] When the air volume needs to be greatly adjusted, since there are two independently installed motors in the fan, one of the motors can be quickly turned off or on according to specific needs, and the fan can be quickly changed into a single-stage or two-stage fan in series. The high-level ventilator avoids the problem that cannot be solved in the single-motor drive, and greatly saves the time taken in the adjustment process of the air volume adjustment, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com