Fiberglas felt for filtering oil smoke and method for producing the same

A glass fiber and oil fume filtration technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of not finding documents, technical materials and reports, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

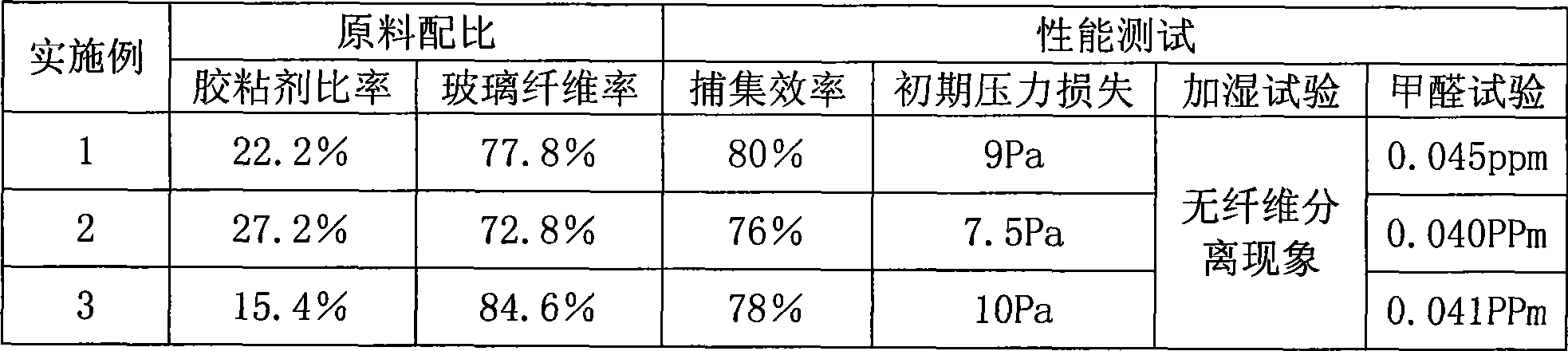

Embodiment 1

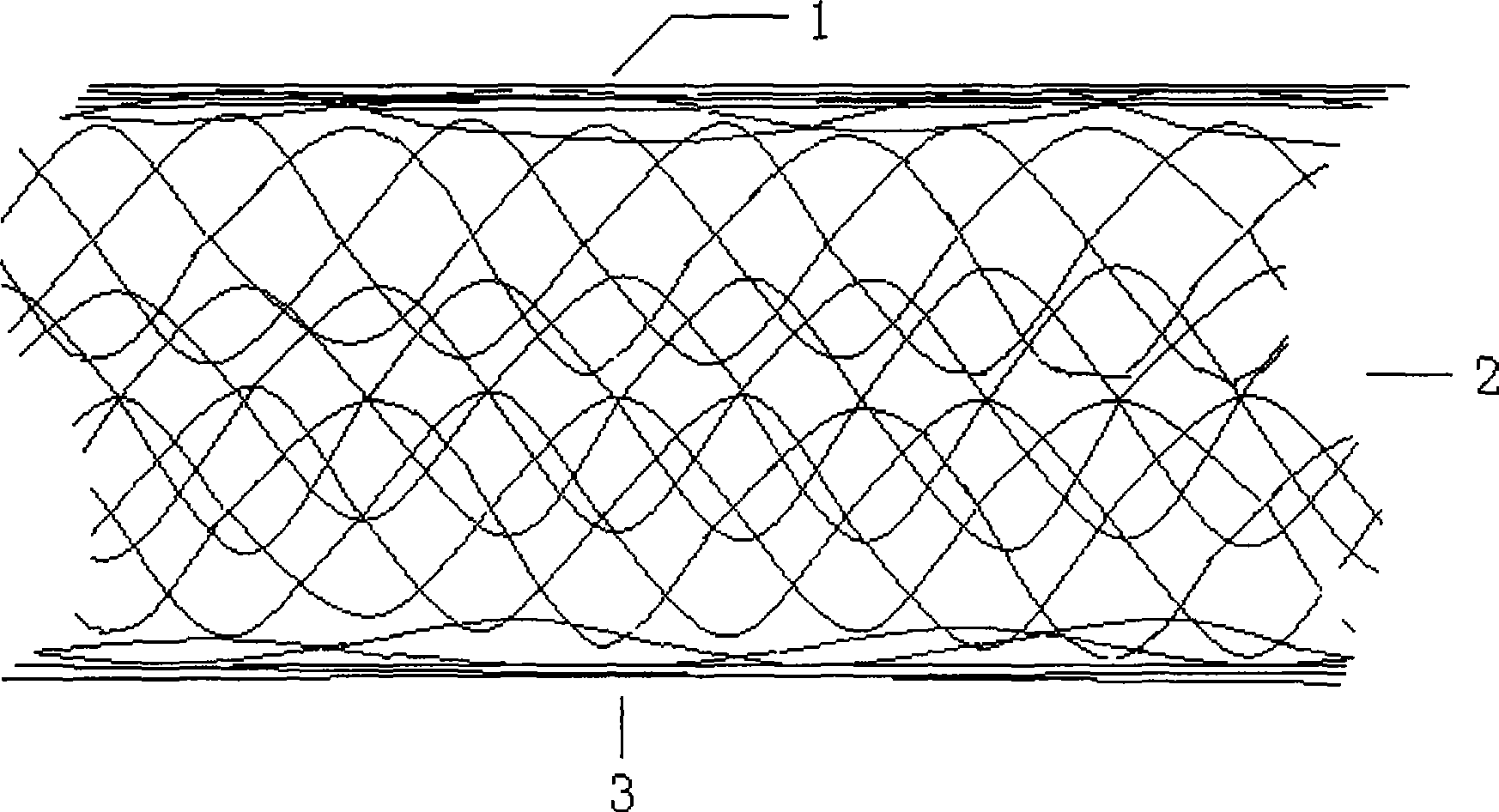

[0016] First put the glass into a 400-hole crucible device, and melt the glass at 1050-1350°C by electric heating. After the glass melts, it becomes a liquid and flows down from the holes to form glass fiber filaments, which are wound on the rotating circle. At the same time, the adhesive is applied on the shaped drum. The running direction of the crucible forms a 90-degree angle with the cross-section of the drum. First, the running speed of the crucible equipment is adjusted to 6±1.2 m / min, and the linear speed of the drum is controlled at 470±50 m. / min. After 50 minutes, adjust the operating speed of the crucible equipment to 7±1.4 m / min, and control the linear speed of the drum rotation at 565±50 m / min. By adjusting the operating speed of the equipment, the glass fiber strands Form different angles to form the middle layer; after 100 minutes, adjust the running speed of the crucible equipment to 6±1.2 m / min, control the linear speed of the drum rotation at 470±50 m / min, an...

Embodiment 2

[0018] First put the glass into a 400-hole crucible device, and melt the glass at 1050-1350°C by electric heating. After the glass melts, it becomes a liquid and flows down from the holes to form glass fiber filaments, which are wound on the rotating circle. At the same time, the adhesive is applied on the shaped drum. The running direction of the crucible forms a 90-degree angle with the cross-section of the drum. First, the running speed of the crucible equipment is adjusted to 6±1.2 m / min, and the linear speed of the drum is controlled at 470±50 m. After 30 minutes, adjust the running speed of the crucible equipment to 7 ± 1.4 m / min, and control the linear speed of the drum rotation at 565 ± 50 m / min. By adjusting the operating speed of the equipment, the glass fiber strands Form different included angles to form the middle layer; after 140 minutes, adjust the operating speed of the crucible equipment to 6±1.2 m / min, control the linear speed of the drum rotation at 470±50 m / ...

Embodiment 3

[0020] First put the glass into a 400-hole crucible device, and melt the glass at 1050-1350°C by electric heating. After the glass melts, it becomes a liquid and flows down from the holes to form glass fiber filaments, which are wound on the rotating circle. At the same time, the adhesive is applied on the shaped drum. The running direction of the crucible forms a 90-degree angle with the cross-section of the drum. First, the running speed of the crucible equipment is adjusted to 6±1.2 m / min, and the linear speed of the drum is controlled at 470±50 m. After 70 minutes, adjust the running speed of the crucible equipment to 7 ± 1.4 m / min, and control the linear speed of the drum rotation at 565 ± 50 m / min. By adjusting the running speed of the equipment, the glass fiber strands Form different angles to form the middle layer; after 60 minutes, adjust the operating speed of the crucible equipment to 6±1.2 m / min, control the linear speed of the drum rotation at 470±50 m / min, and sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com