Method for producing steel component integrally having rubber portion

A technology for steel parts and a manufacturing method, which is applied in the field of integrated steel parts manufacturing with rubber parts, can solve the problems of reduced rust resistance and increased manufacturing costs, and achieves excellent water-resistant bonding, Effect of deterioration of rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

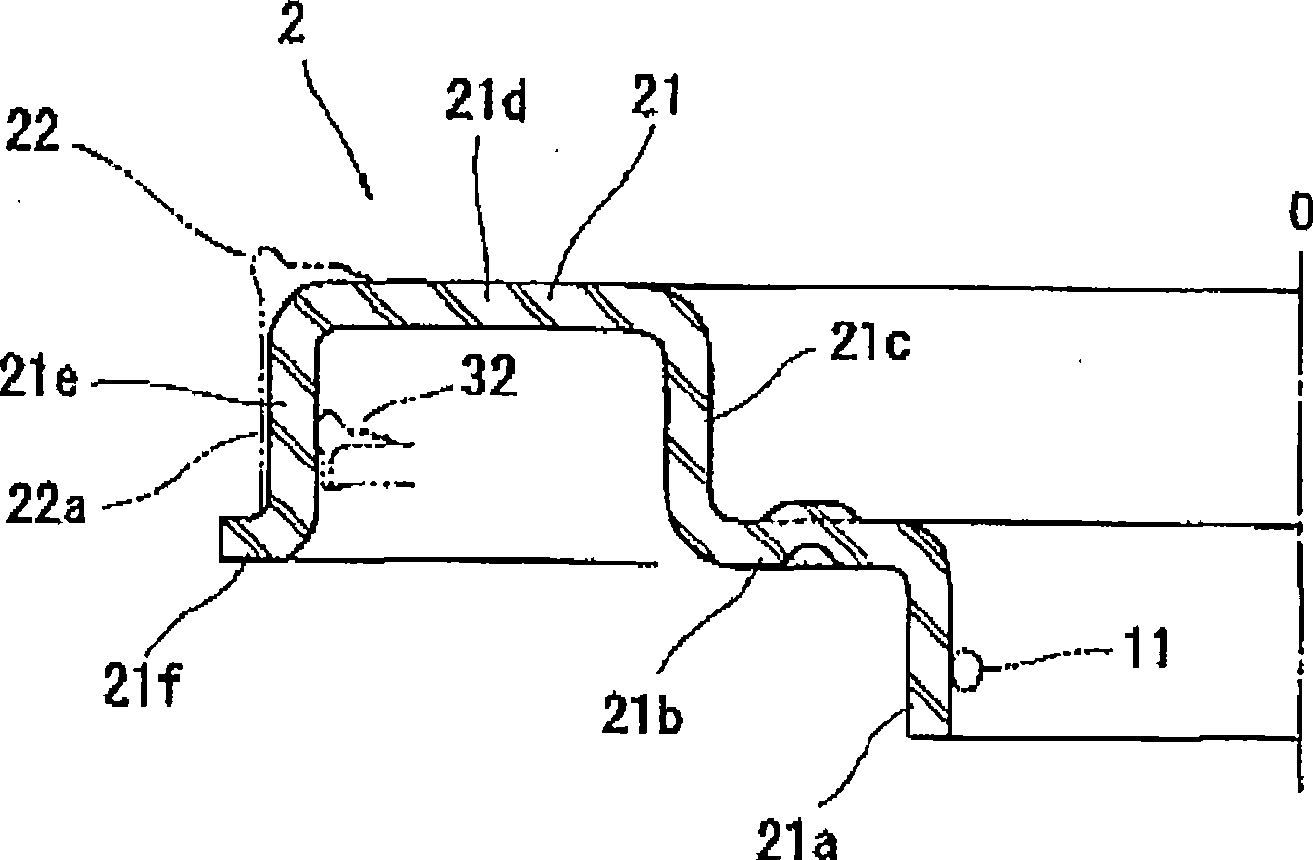

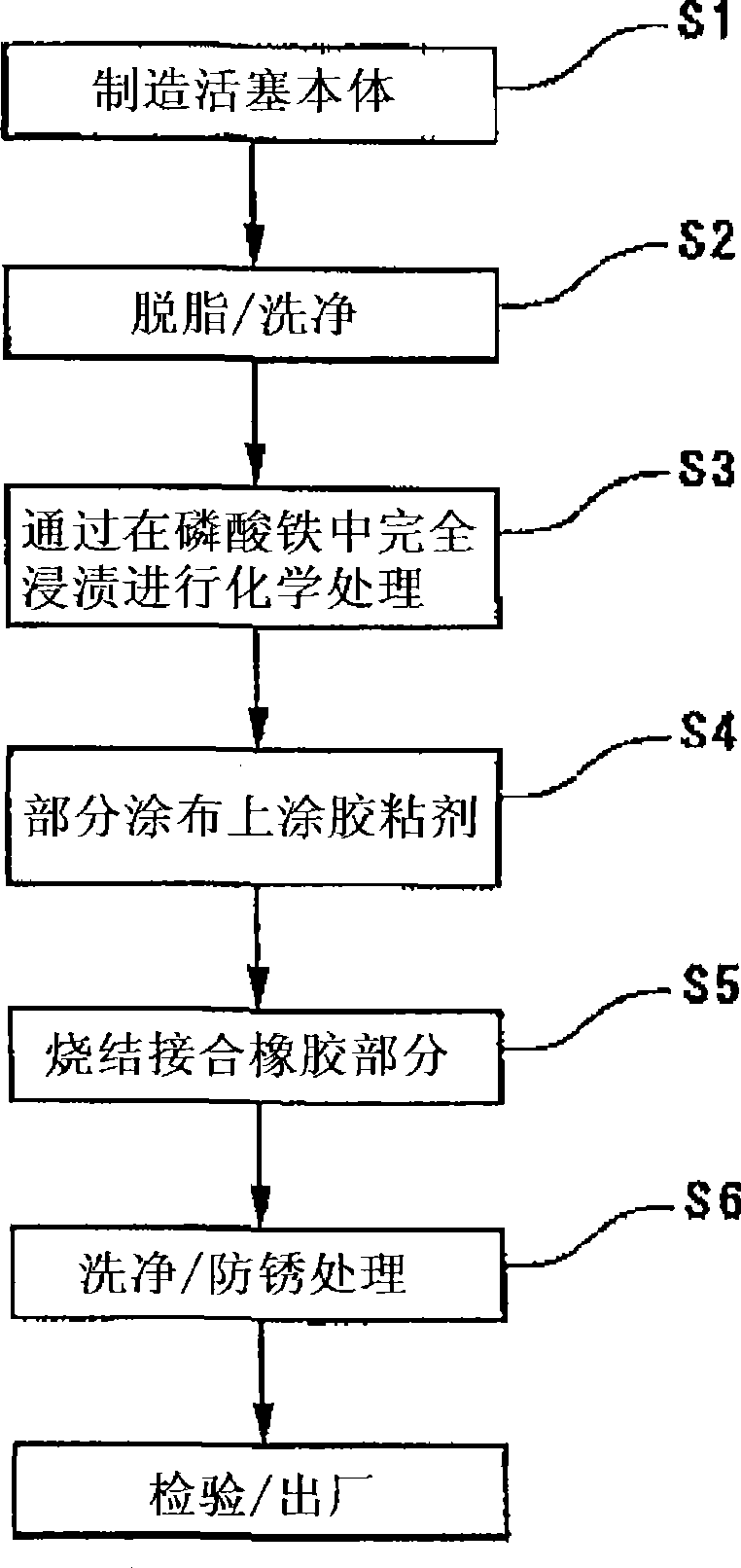

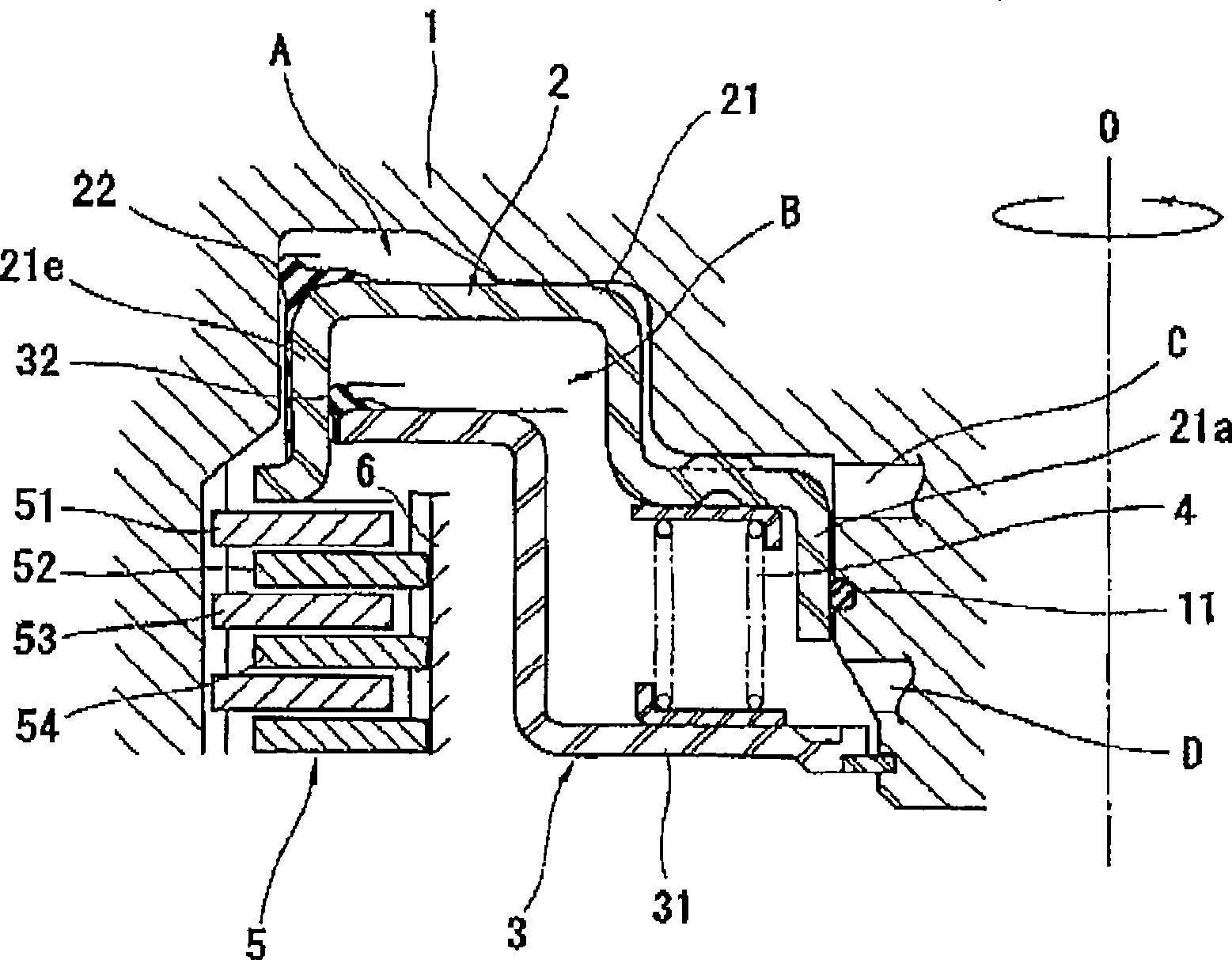

[0030] A preferred embodiment of the method for manufacturing a steel part having a rubber portion integrally according to the present invention will be described below with reference to the drawings. first, figure 1 It is the manufacturing object of the manufacturing method of an integrated steel part with a rubber part related to the present invention, and the half side sectional view of the sealed integrated piston is cut by a plane passing through the axis center, figure 2 It is a process flow chart showing the manufacturing method of the integrated steel part which has a rubber part concerning this invention.

[0031] exist figure 1 The seal-integrated piston 2 shown in is equivalent to the integrated steel part with rubber part described in the present invention, and has the same image 3 The same structure as shown in , that is to say, consists of a piston body 21 manufactured by steel sheet stamping / press forming, etc., and a sealing lip 22 integrally sintered and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com