Fuzzy control heating apparatus of full automatic soya-bean milk machine

A technology of fuzzy control and heating device, applied in the direction of computer control, program control, general control system, etc., can solve the problems of reducing work reliability and safety, complex circuit structure, heating element heating, etc., to ensure work safety and safety. Reliability, sufficient decomposition of proteins, and the effect of preventing damage to heating elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment : pic 1 1 specific Embodiment approach

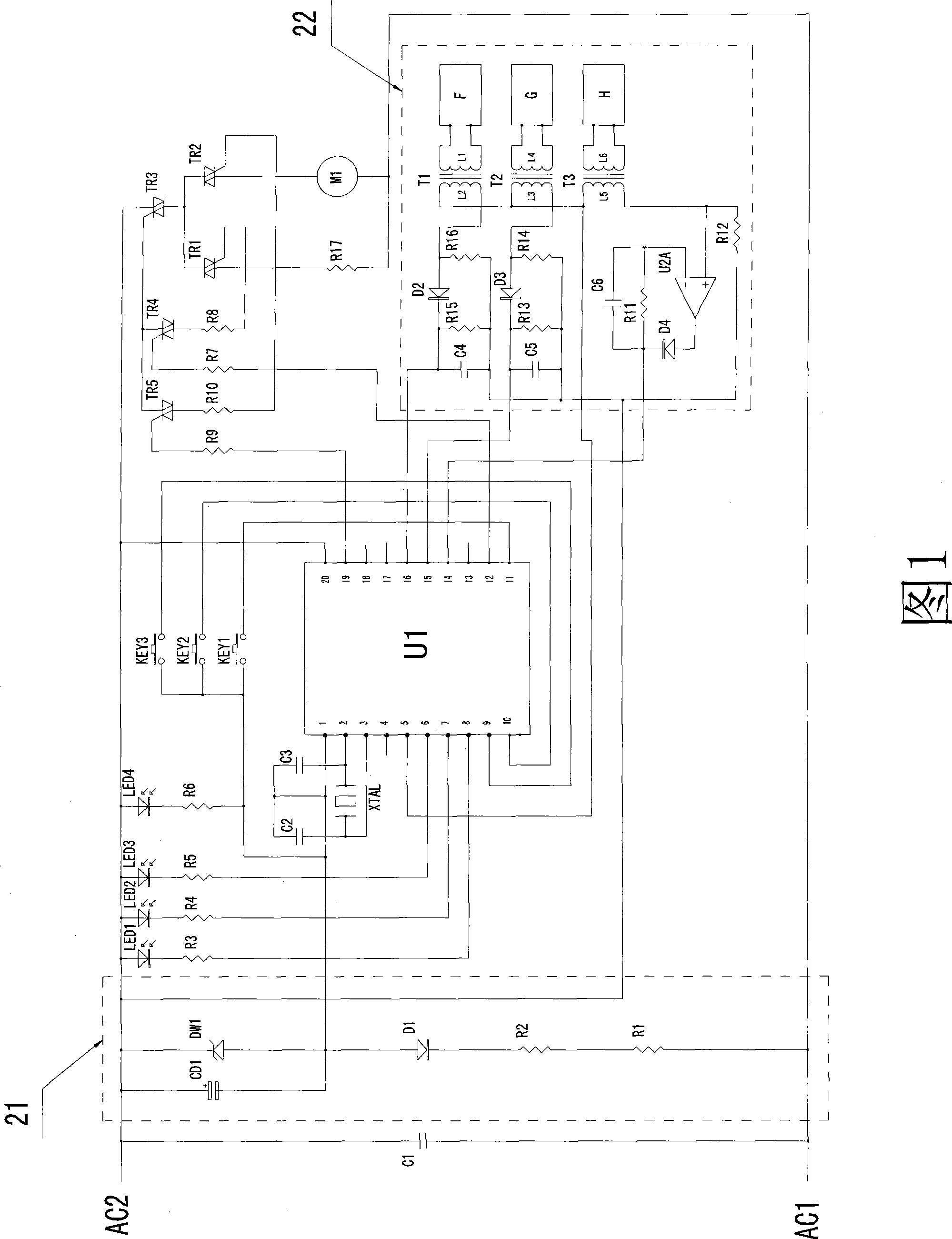

[0022] Example: Fig. 1 shows a specific implementation of the fuzzy control heating device of the fully automatic soybean milk machine of the present invention: it includes an AC power supply, a resistance step-down power supply circuit 21, a single-chip microcomputer U1, a heating control unit, a motor control unit and Sensing control unit 22 .

[0023] The AC power supply is 220V commercial power, and one input terminal AC1 is connected to the live wire; the other input terminal AC2 is connected to the neutral wire, and the potential is 0V, which is also the ground terminal. In this embodiment, a capacitor C1 is connected between the input ends AC1 and AC2 of the AC power supply.

[0024] The resistance step-down power supply circuit 21 is composed of two step-down resistors R1 and R2, a rectifier diode D1, a zener diode DWI and a filter capacitor CD1 that are connected together. The cathode of the rectifier diode D1 is connected to the AC power input terminal AC1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com