LED lamp with heat radiation structure

A technology of light emitting diode and heat dissipation structure, which is applied to the semiconductor device of light emitting element, light source, light source fixing and other directions, can solve the problems of easy heat generation, noise generation, increase power consumption of light emitting diode lamps, etc., to achieve good heat dissipation effect, The effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

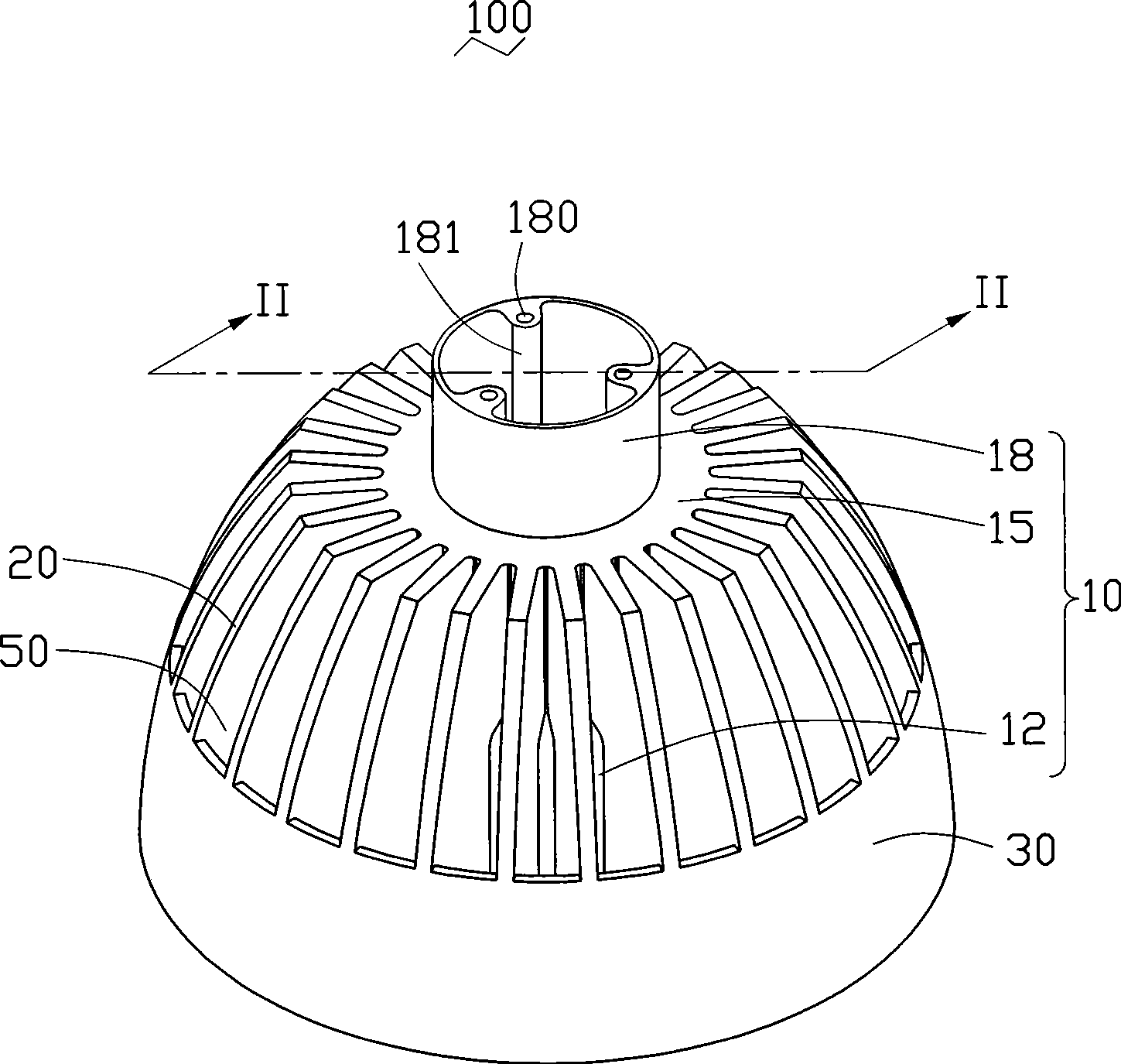

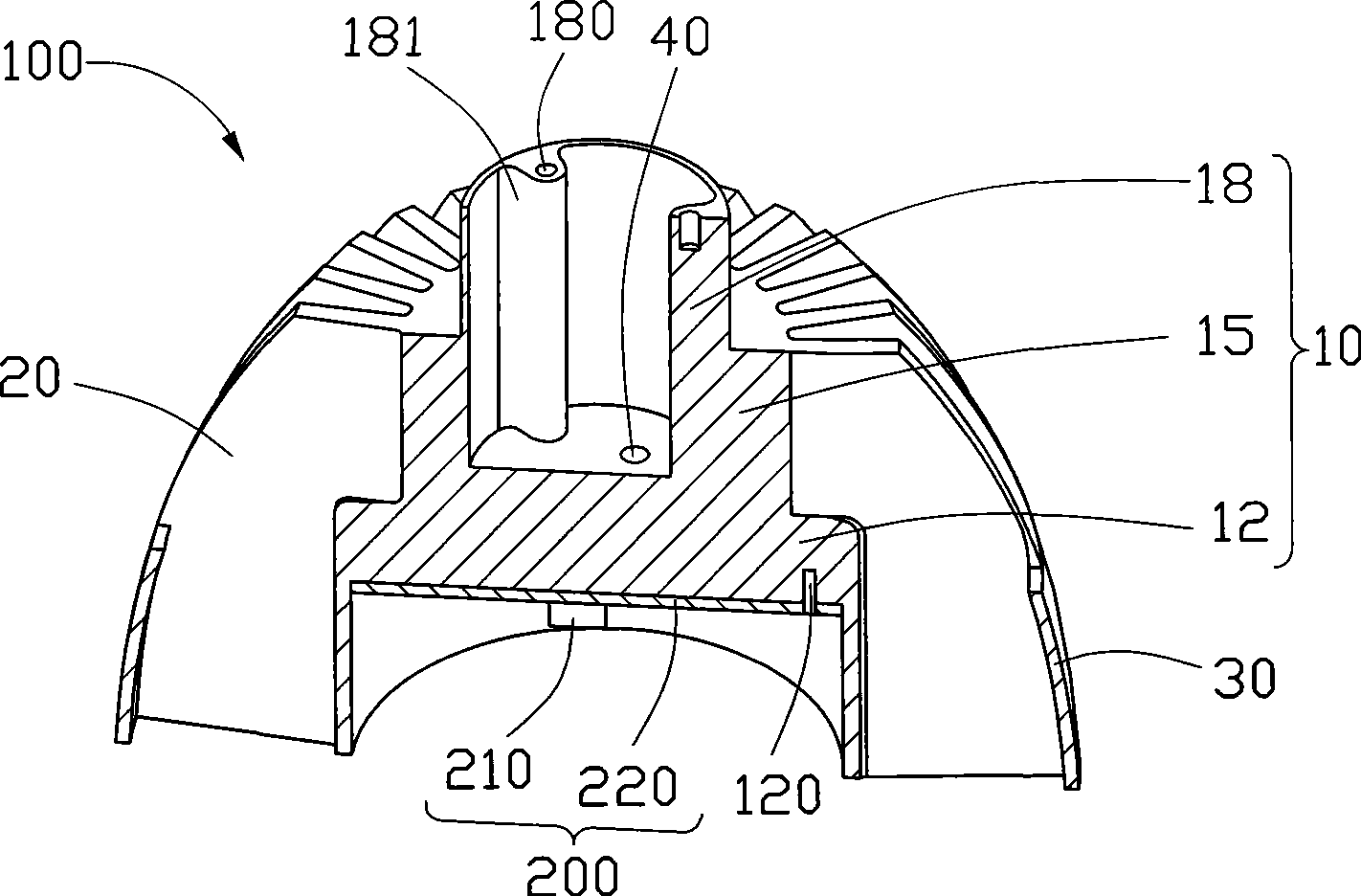

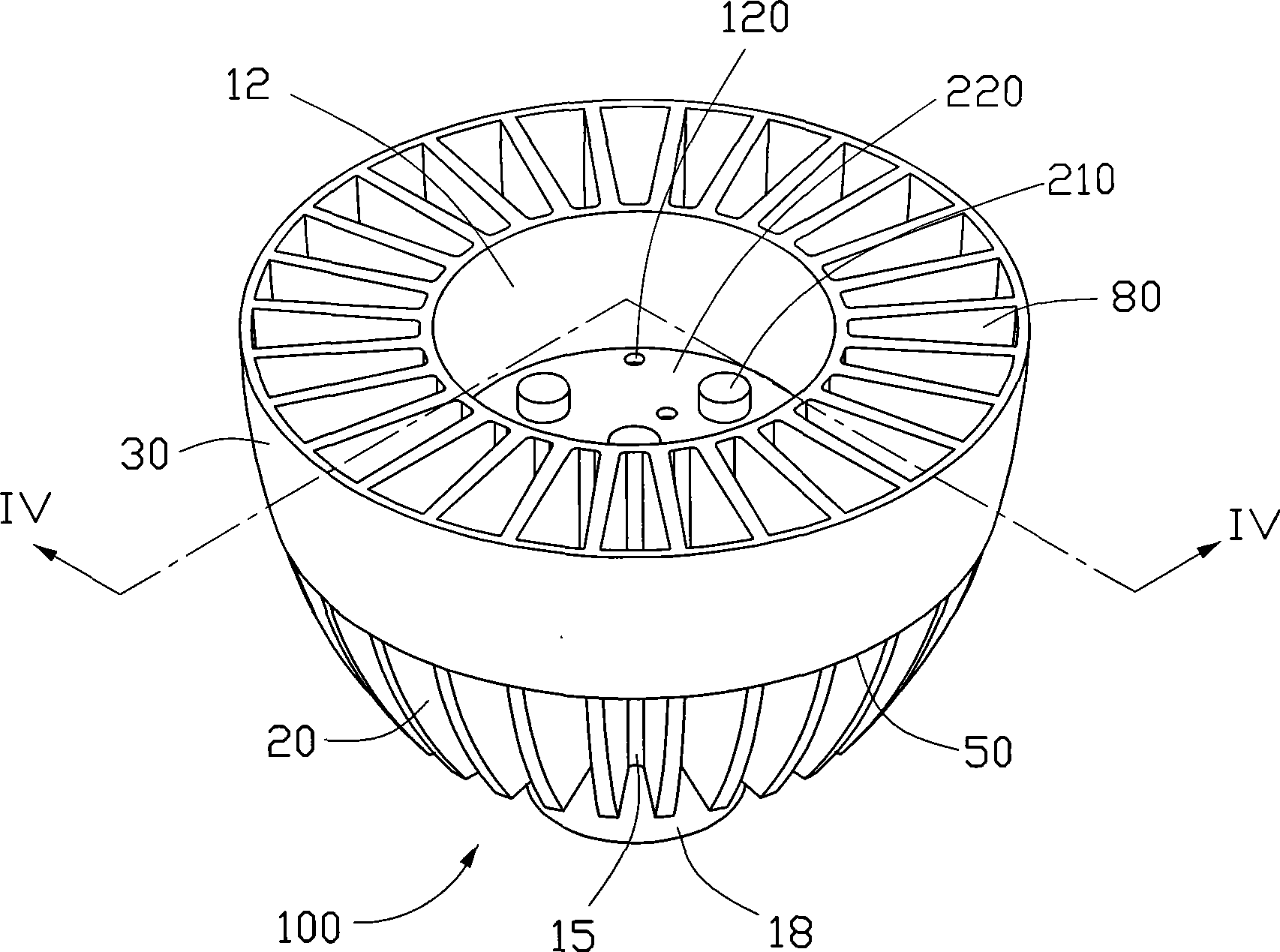

[0014] like Figure 1-2 As shown, the LED lamp of the present invention is composed of an LED module 200 and a heat sink 100 for affixing the LED module 200 . The heat sink 100 is roughly hemispherical, and its outer diameter gradually decreases from the lower end to the upper end along the axial direction. The heat sink 100 includes a main body 10 , a plurality of cooling fins 20 extending outward from the outer surface of the main body 10 , and a housing 30 surrounding the lower half of the cooling fins 20 which has a larger outer diameter.

[0015] Please also refer to Figure 3 to Figure 6 The main body 10 has a heat absorbing portion 12 , a heat transfer portion 15 extending from one end of the heat absorbing portion 12 , and a connecting portion 18 . The connecting portion 18 extends from the other end of the heat transfer portion 15 opposite to the heat absorbing portion 12 , and exceeds the top of the heat sink 20 . The heat absorbing part 12 , the heat transfer par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com