Non-ferrous metal smelting side blowing furnace spray gun

A non-ferrous metal, side-blowing furnace technology, applied in the direction of gas fuel burner, combustion method, combustion type, etc., can solve the problem of unsatisfactory spray gun effect of non-ferrous metal smelting side-blowing furnace, to save installation position, strengthen strength and rigidity , good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

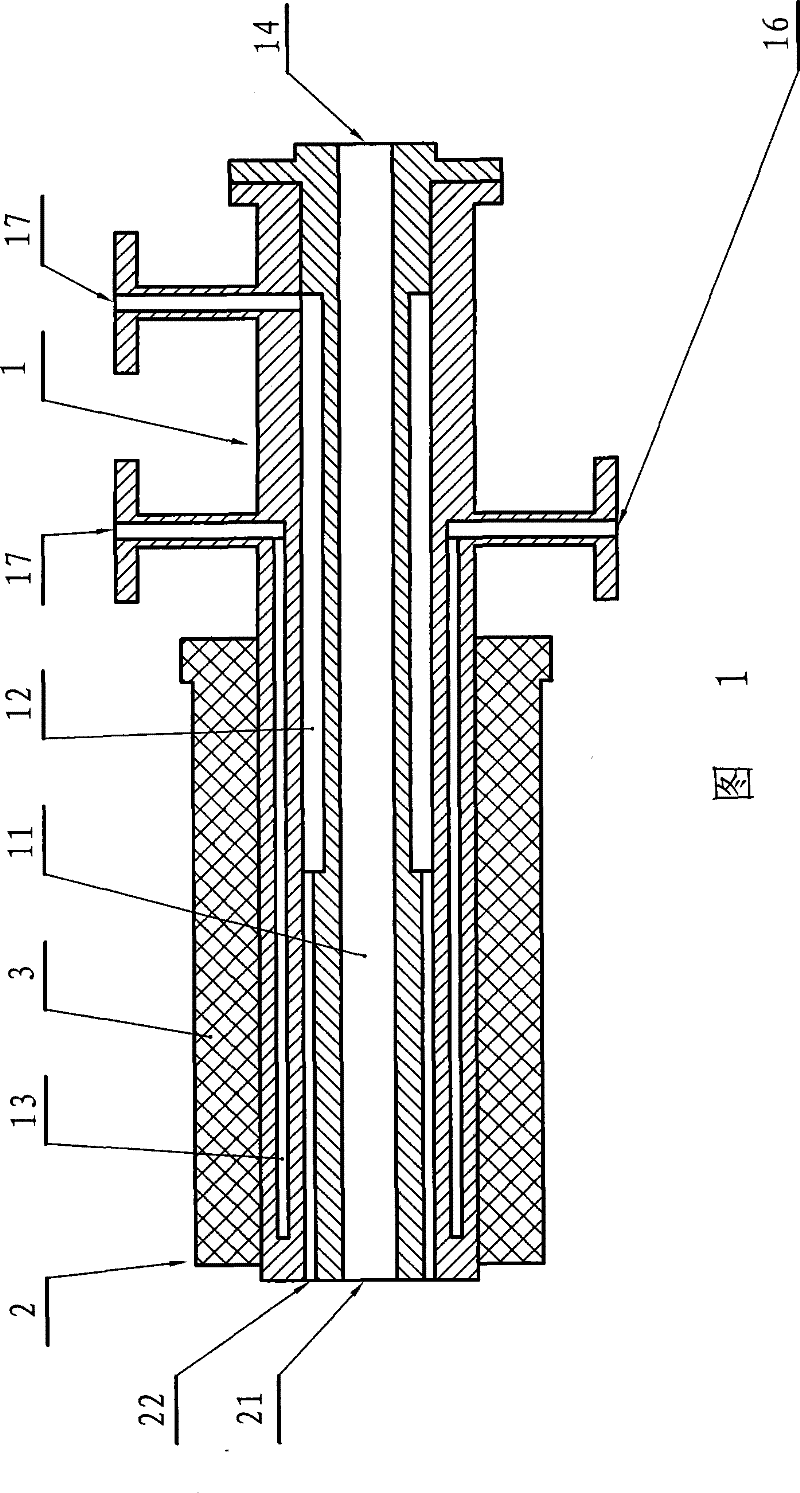

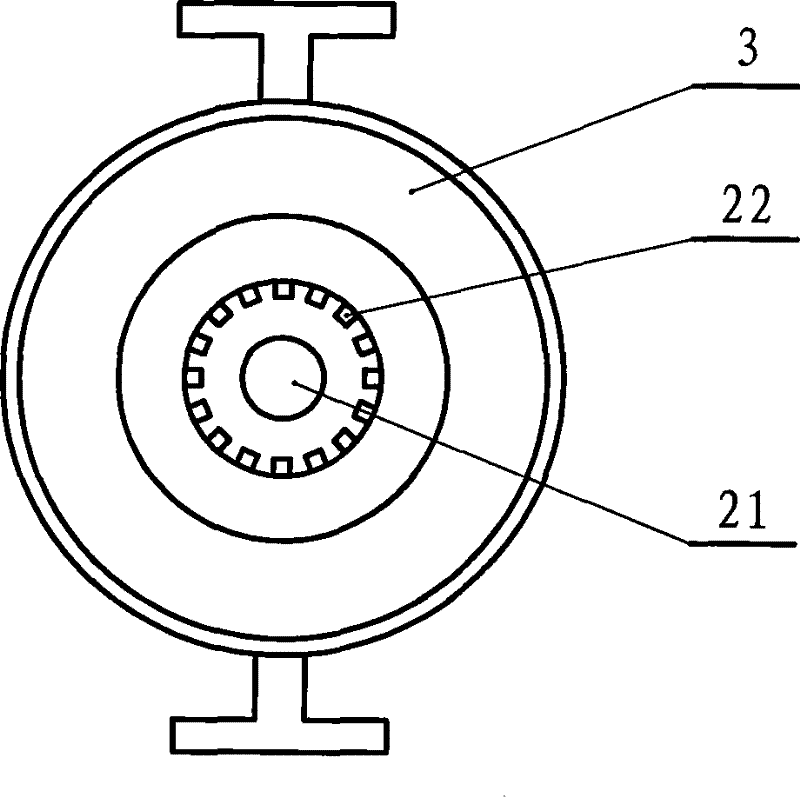

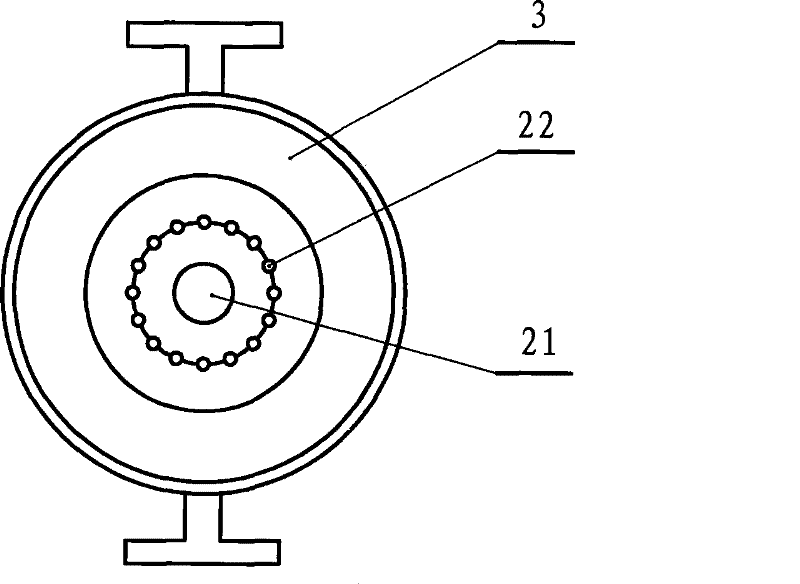

[0026] The non-ferrous metal smelting side blowing furnace lance of the present invention comprises a lance body 1 of a casing structure and a lance head 2 at the front end of the lance body, a fuel passage 11 is provided at the center of the casing structure, and a sandwich annular passage is provided on the periphery of the fuel passage 11 Combustion-supporting gas channel 12, the periphery of combustion-supporting gas channel 12 is provided with interlayer annular channel cooling water channel 13. The center of the spray gun head 2 is provided with a fuel nozzle 21, and the fuel nozzle 21 is adapted to the front end of the fuel passage 11, and the periphery of the fuel nozzle 21 is provided with a combustion-supporting gas nozzle of a through-hole nozzle array adapted to the combustion-supporting gas passage 12 of the interlayer annular passage 22. The number of combustion-supporting gas nozzles 22 is usually several to more than a dozen. According to the actual needs of sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com