Method for producing large area holographic grating based on second exposure of reference grating

A technology of reference grating and holographic grating, applied in the field of preparation of holographic diffraction grating, can solve the problems of difficulty in stability, limited engineering practicability, difficult splicing process, etc., and achieves a simple and easy preparation method, and ensures parallel accuracy and phase relationship. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

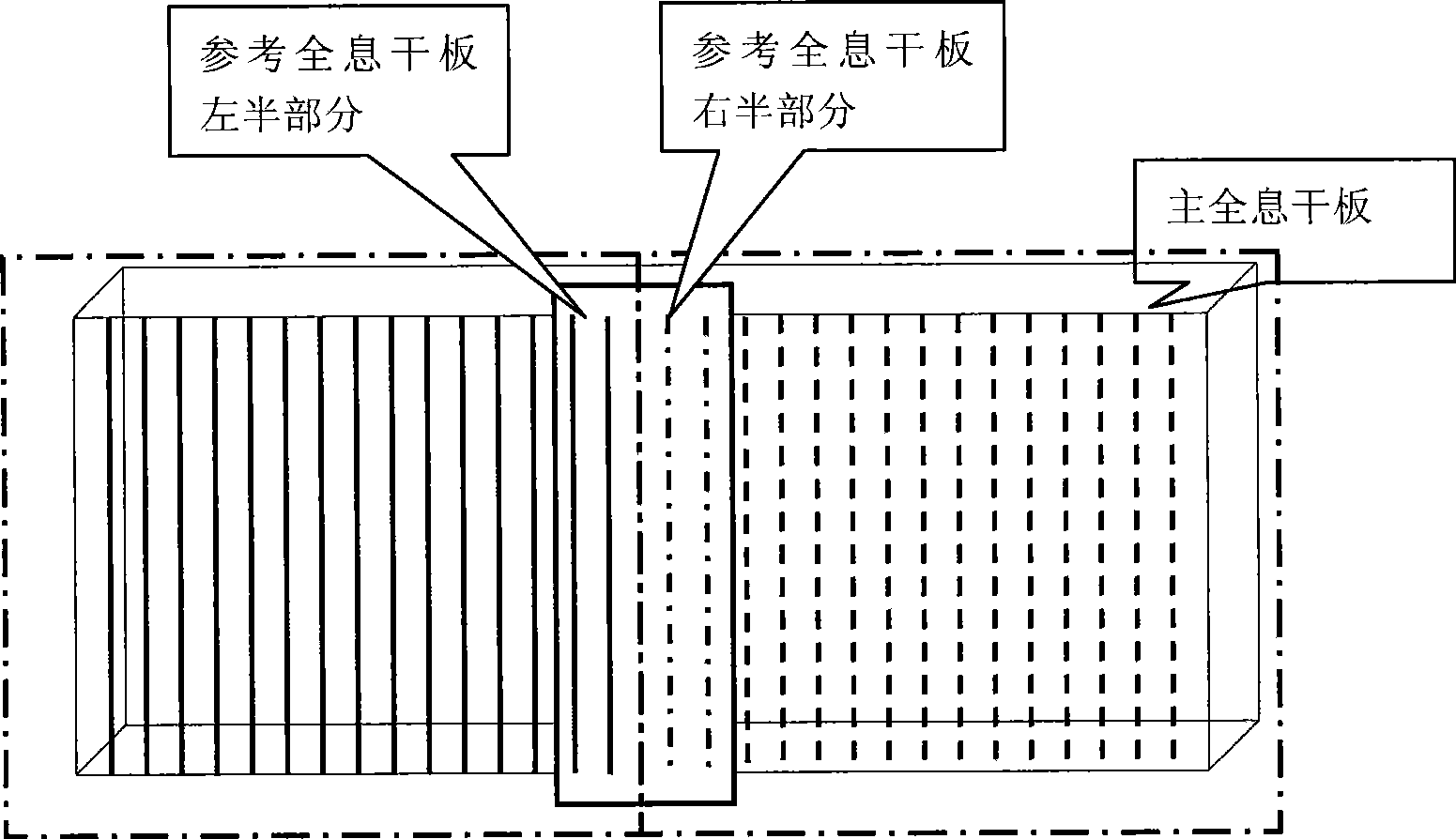

[0026] Embodiment one: see attached figure 2 to attach Figure 7 As shown, a large-area holographic grating preparation method based on the second exposure of the reference grating, the diffraction grating is prepared on the main holographic dry plate coated with photosensitive materials, and the optical characteristics of the reference grating are used to control the double exposure of the main grating to achieve accurate splicing , the process is as follows:

[0027] 1. Place the reference holographic dry plate coated with photosensitive material on the front and middle of the main holographic dry plate (grating to be spliced) and relatively fix it on the exposure bracket to ensure that the reference holographic dry plate and the main holographic dry plate are maintained during the movement. relatively static. as attached figure 2 shown.

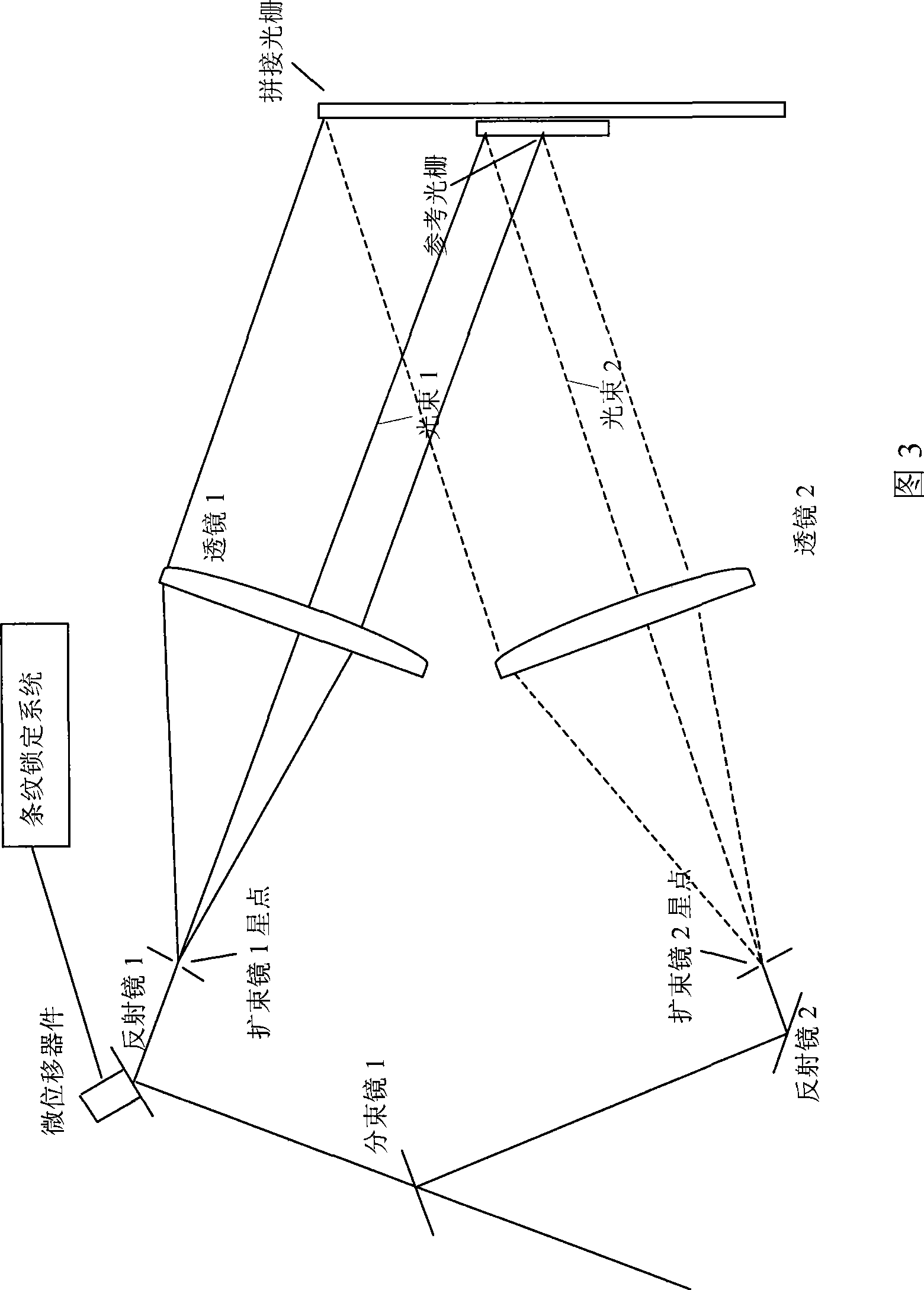

[0028] 2. Place the main holographic dry plate and the left half of the reference holographic dry plate in the holographic recordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com