Method for preparing poly hexane diacid-terephthalic acid-butylene terephthalate foaming material

A technology of terephthalic acid and polyadipic acid, applied in the production of bulk chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

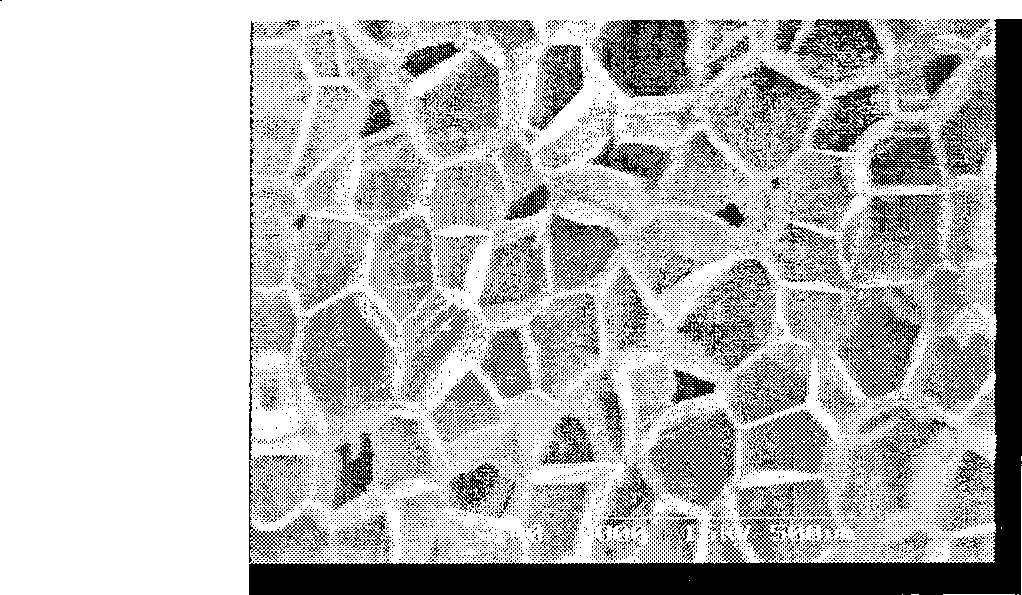

Embodiment 1

[0025] The PBAT material is placed in the autoclave, wherein the volume of the PBAT material is not greater than one-twentieth of the volume of the autoclave, so as to ensure that the PBAT material has enough space for foaming. Close the autoclave and fill the autoclave with low-pressure CO 2 Purge for several minutes to displace the air in the kettle. Place the high-pressure reactor in a water bath at 85°C, and use a high-pressure pump to pump CO 2 Fill the autoclave until the pressure reaches 20MPa, and swell for 2 hours. Then quickly relieve the pressure until the gauge pressure is normal pressure, and the pressure relief rate is 5MPa / s. The sample was taken out, and its quenched surface was analyzed by scanning electron microscope. The cell diameter of the PBAT foamed sample is 40.23 μm, and the cell density is 8.36×10 7 piece / cm 3 , the foamed sample expands about 10 times compared to the volume of the raw material. From the point of view of the cell shape, the cell...

Embodiment 2

[0027] The PBAT material is placed in the autoclave, wherein the volume of the PBAT material is not greater than one-twentieth of the volume of the autoclave, so as to ensure that the PBAT material has enough space for foaming. Close the autoclave and fill the autoclave with low-pressure CO 2 Purge for several minutes to displace the air in the kettle. Place the high-pressure reactor in a water bath at 85°C, and use a high-pressure pump to pump CO 2Fill the autoclave until the pressure reaches 14MPa, and swell for 2 hours. Then quickly relieve the pressure until the gauge pressure is normal pressure, and the pressure relief rate is 5MPa / s. The sample was taken out, and its quenched surface was analyzed by scanning electron microscope. Then quickly relieve the pressure until the gauge pressure is normal pressure, and the pressure relief rate is 5MPa / s. The sample was taken out, and its quenched surface was analyzed by scanning electron microscope. The cell diameter of the ...

Embodiment 3

[0029] The PBAT material is placed in the autoclave, wherein the volume of the PBAT material is not greater than one-twentieth of the volume of the autoclave, so as to ensure that the PBAT material has enough space for foaming and molding. Close the autoclave and fill the autoclave with low-pressure CO 2 Purge for several minutes to displace the air in the kettle. Place the high-pressure reactor in a water bath at 85°C, and use a high-pressure pump to pump CO 2 Fill the autoclave until the pressure reaches 10MPa, and swell for 2 hours. Then quickly relieve the pressure until the gauge pressure is normal pressure, and the pressure relief rate is 5MPa / s. The sample was taken out, and its quenched surface was analyzed by scanning electron microscope. The cell diameter of the PBAT foamed sample is 58.13 μm, and the cell density is 9.55×10 6 piece / cm 3 , the foamed sample expands about 5 times in volume compared with the raw material. The experimental results such as cell dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell diameter | aaaaa | aaaaa |

| Cell diameter | aaaaa | aaaaa |

| Cell diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com