Hydrogenation substation

A technology of sub-stations and sub-stations, applied in the field of new energy, can solve the problems of limited effective service radius, difficult site selection, large floor space, etc., to achieve the effect of improving effective service radius, large activity range and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The contents, advantages and objects of the present invention will be set forth in the following description of the embodiments.

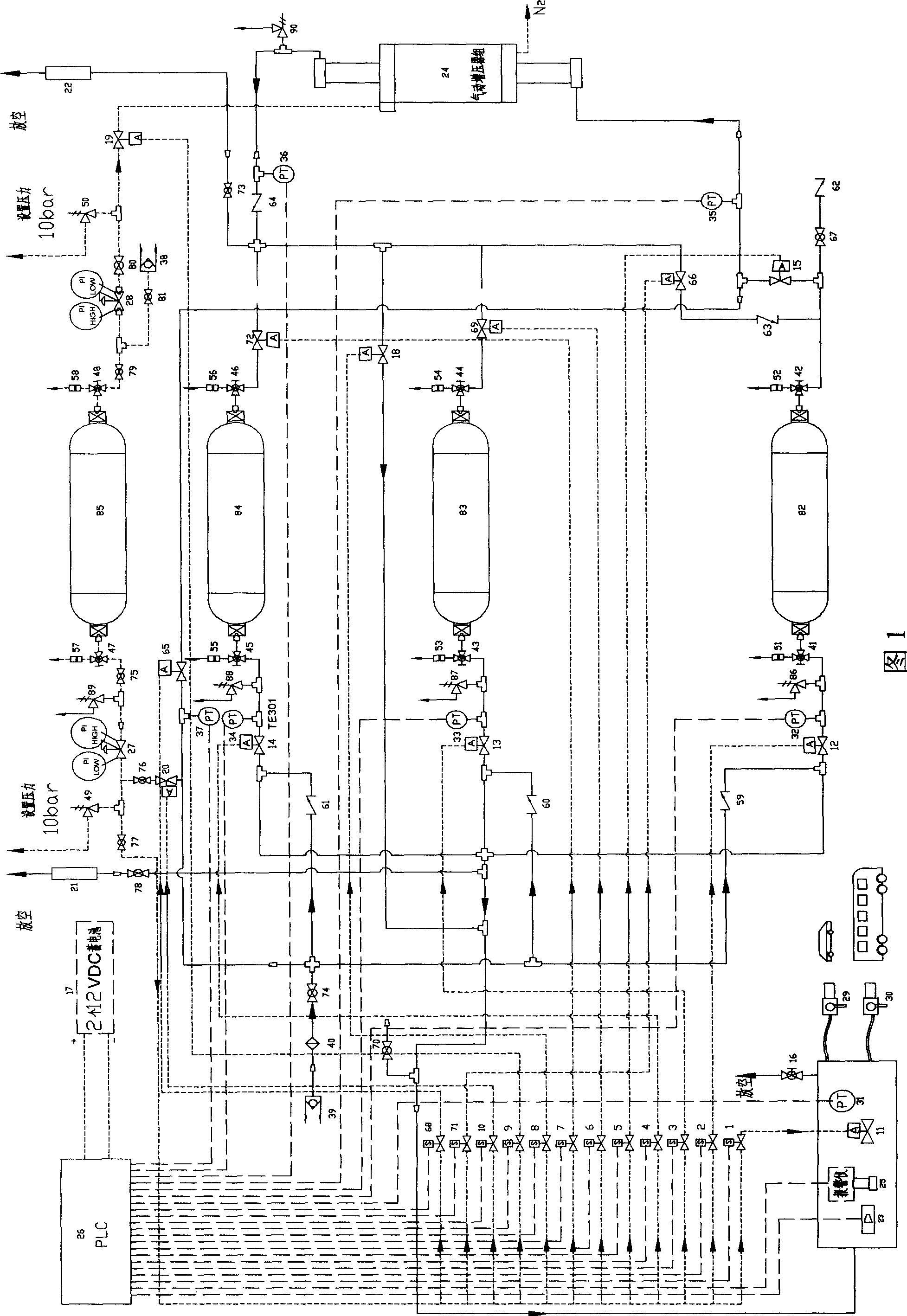

[0034] According to the present invention, the sub-station of the hydrogen refueling station is composed of a tractor head, a semi-trailer, and a detachable integrated skid that can be fixed on the semi-trailer. The skid-mounted parts are composed of a gas loading system, a high-pressure gas storage system, a hydrogen pressurization system, a hydrogen unloading system, a high-pressure hydrogen filling system, a control system and an auxiliary system.

[0035] When designing a fixed hydrogen refueling station (parent station), in order to meet the filling capacity during the peak filling period, the compressor is usually required to have a large boosting capacity. During most of the day, the utilization rate of the compressor in the parent station is low, and there is a surplus of pressurization capacity. The sub-station (sub-station) of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com