Star type and spiral combined coal supply apparatus

A feeding device and screw feeding technology, applied in lighting and heating equipment, combustion methods, block/powder supply/distribution, etc., can solve the problems of coking at the feeding port, difficult to grasp the length of the material plug, and difficult to form the material plug, etc. Achieve the effect of prolonging service life, shortening residence time and reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

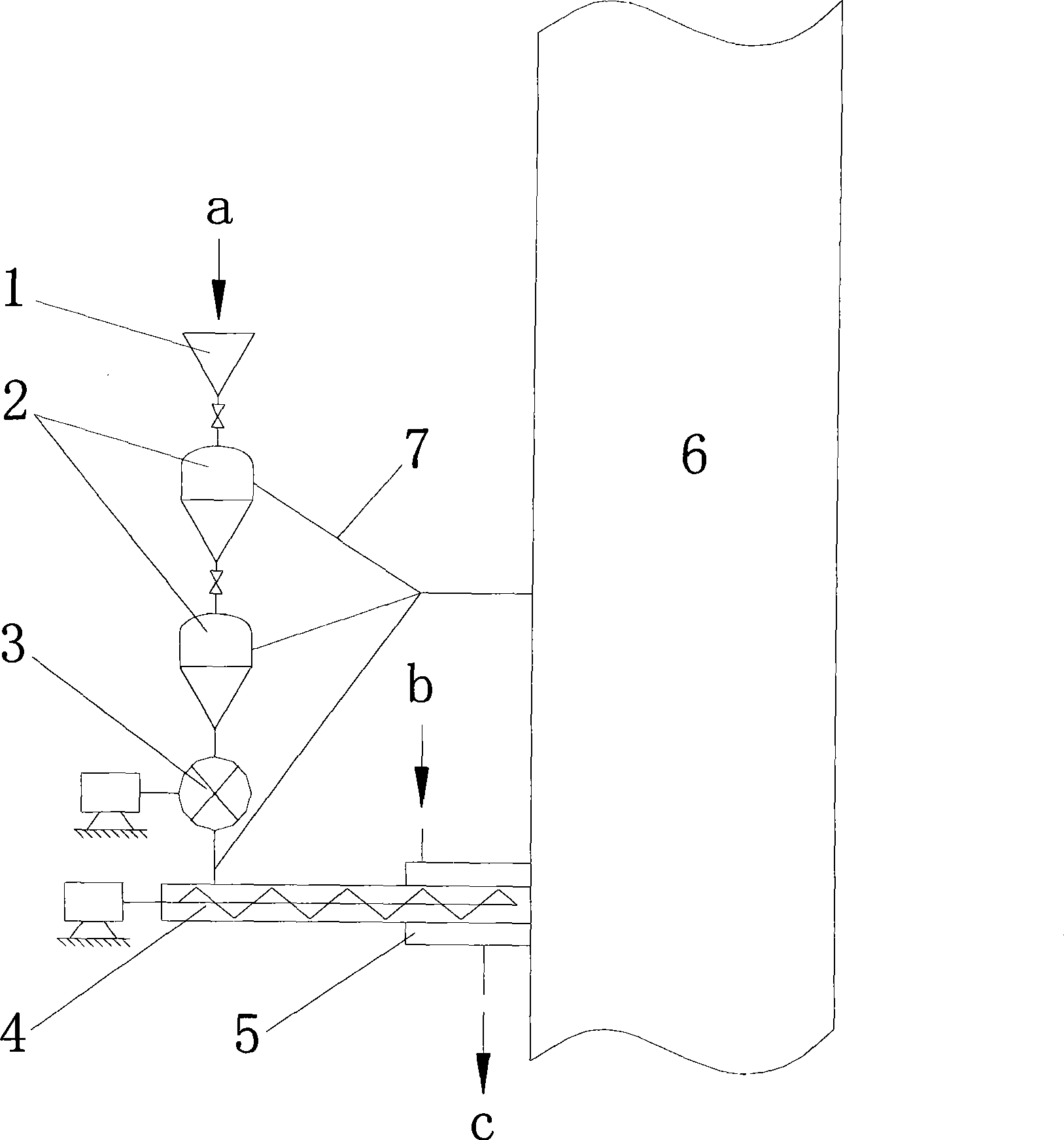

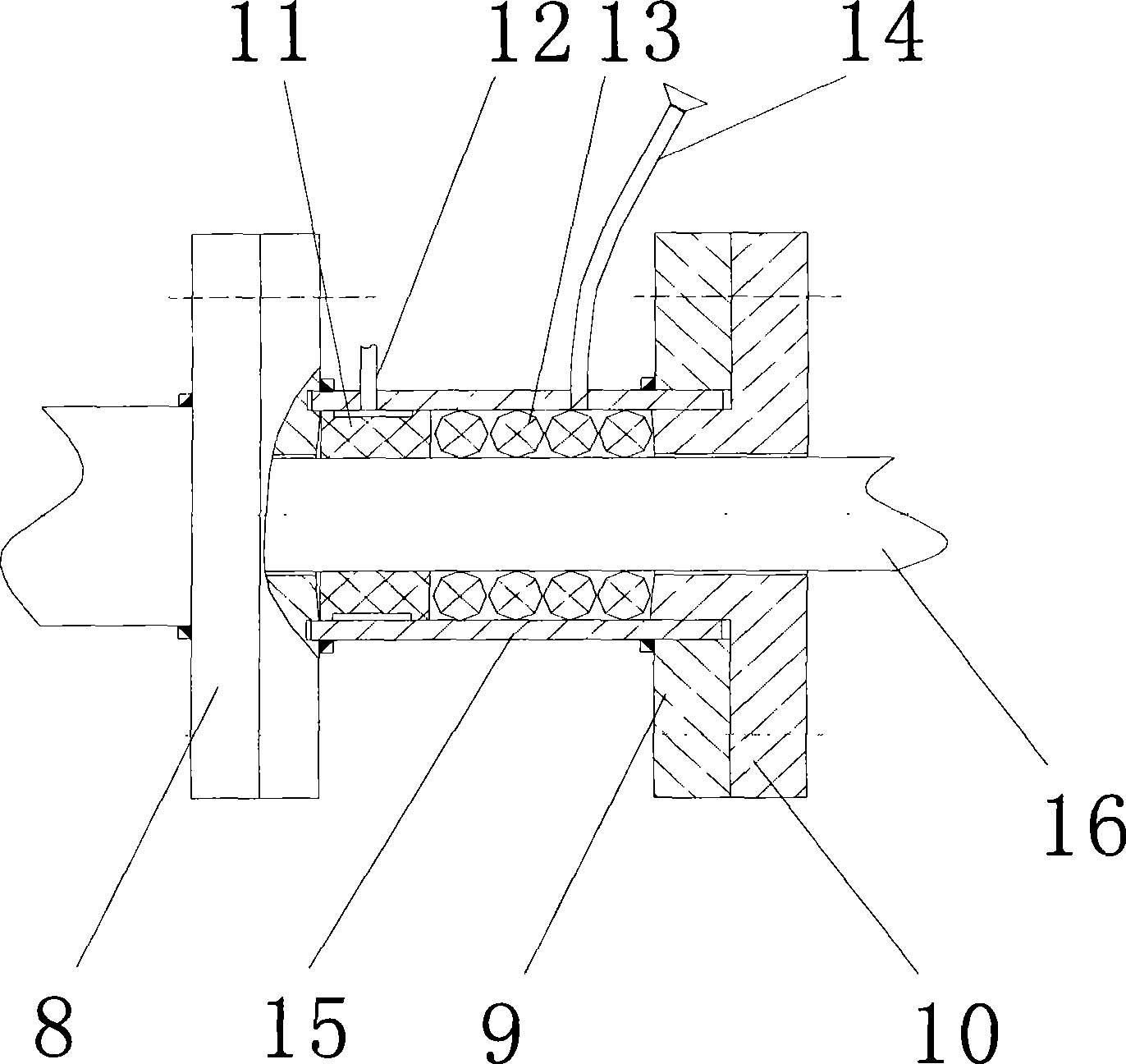

[0018] The device is composed of a star feeding device and a spiral feeding device connected in series; the lower part of the feeding hopper 1 is connected with a double lock hopper device 2, and the lower part of the double lock hopper device 2 is connected with a star feeding device 3, the outlet of the star feeding device 3 and the screw The inlet of the feeding device 4 is connected; the outlet of the screw feeding device 4 is connected with the furnace 6; the water-cooling jacket 5 is arranged on the metal pipe shell at the outlet of the spiral feeding device 4, the furnace 6 is connected with the double lock bucket device 2, the star feeding device 3, the spiral A pressure balance pipe 7 is provided between the feeding device 4.

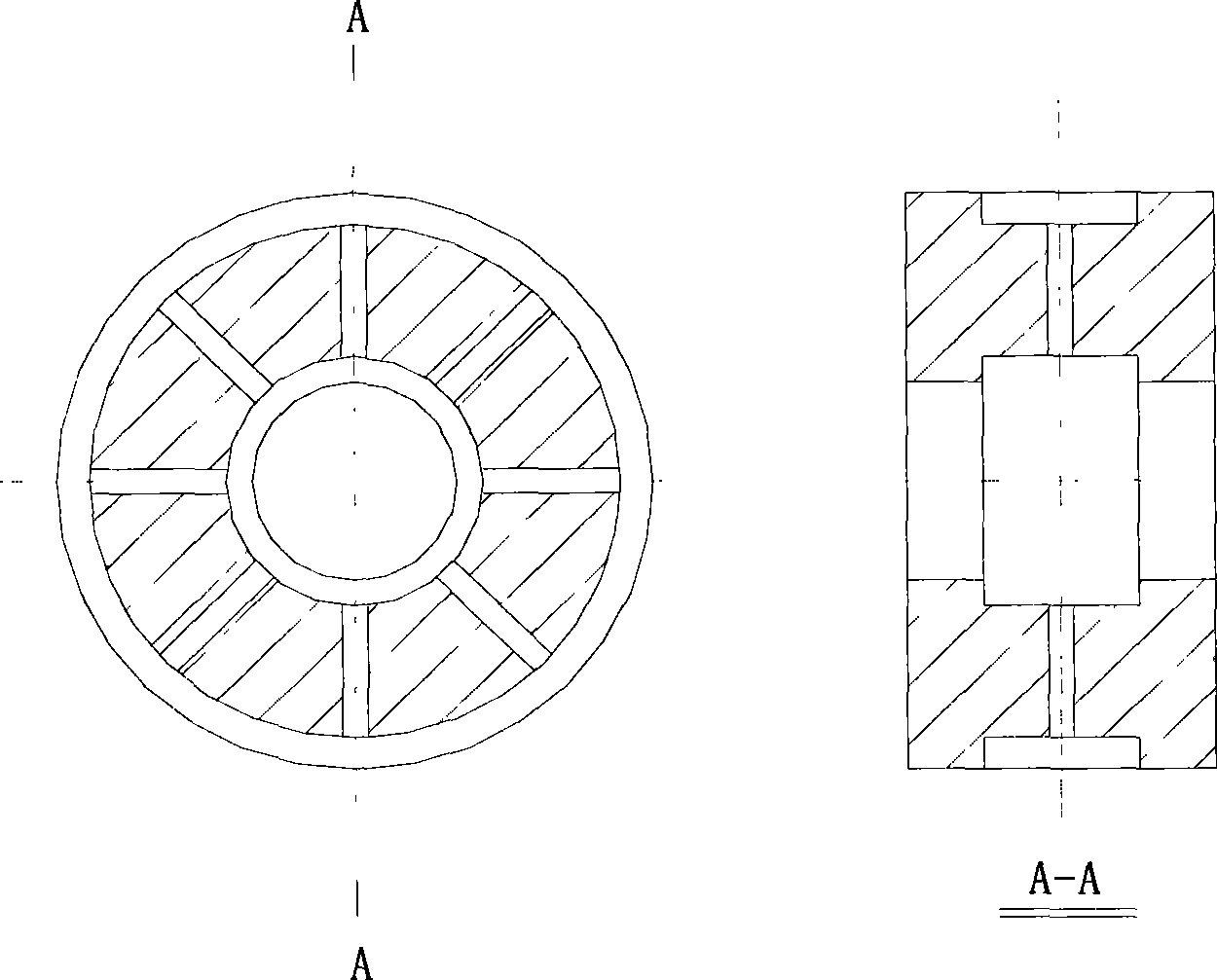

[0019] The sealing at the rotating shaft 16 of the star-shaped feeding device 3 and the screw feeding device 4 adopts an air-cushion and packing hybrid sealing device, which is arranged between the outer casing 15 and the rotating shaft 16 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com