Borehole allocation method on large marine shafting ground

A marine shafting and boring technology, which is applied in the field of hole matching and boring, can solve the problems of not being able to fully meet the needs of processing, long-term occupation of machine tools, and overall length, so as to avoid digging, improve production efficiency, and reduce tool loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

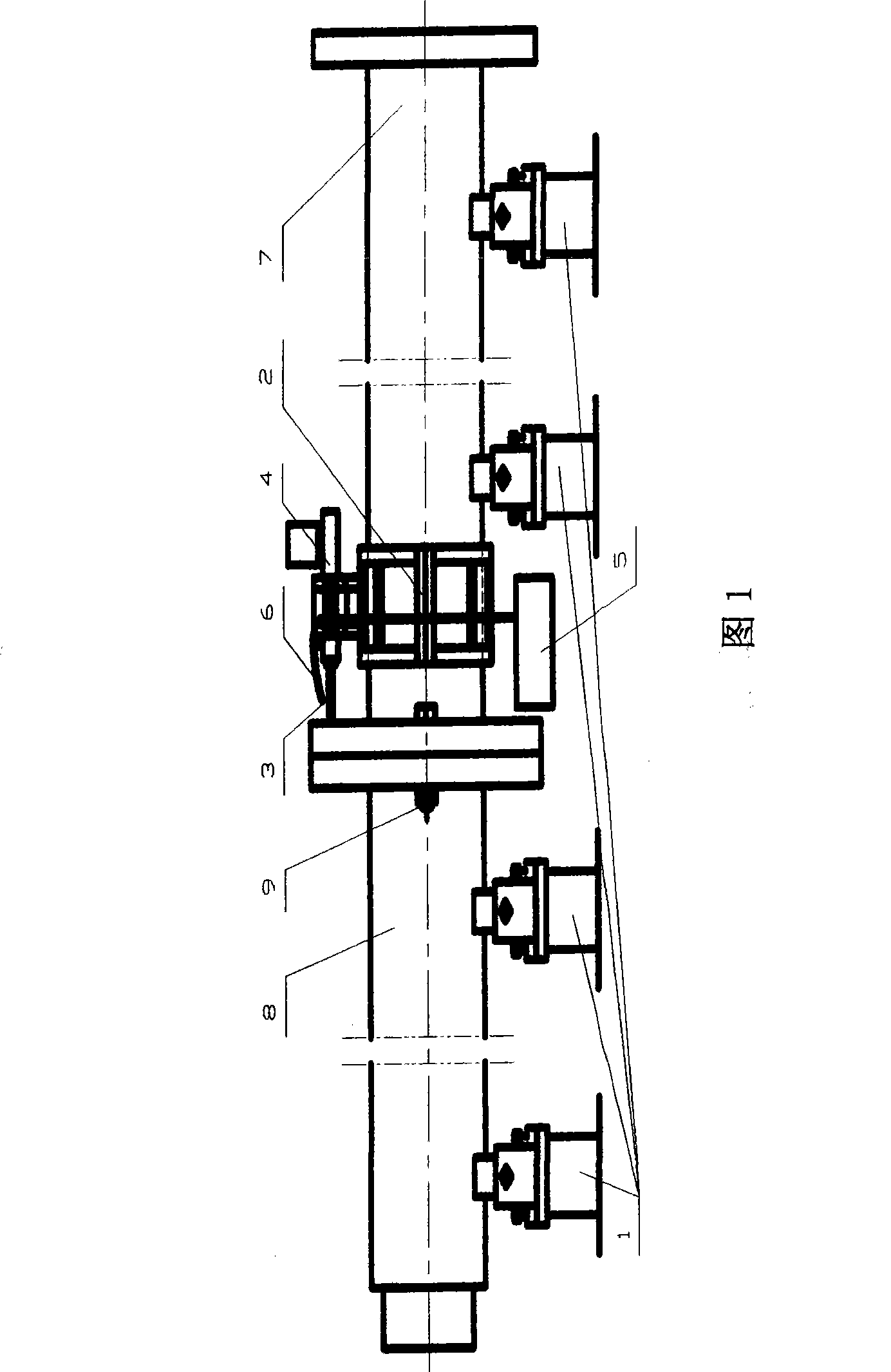

[0015] With reference to Fig. 1, concrete steps of the present invention are:

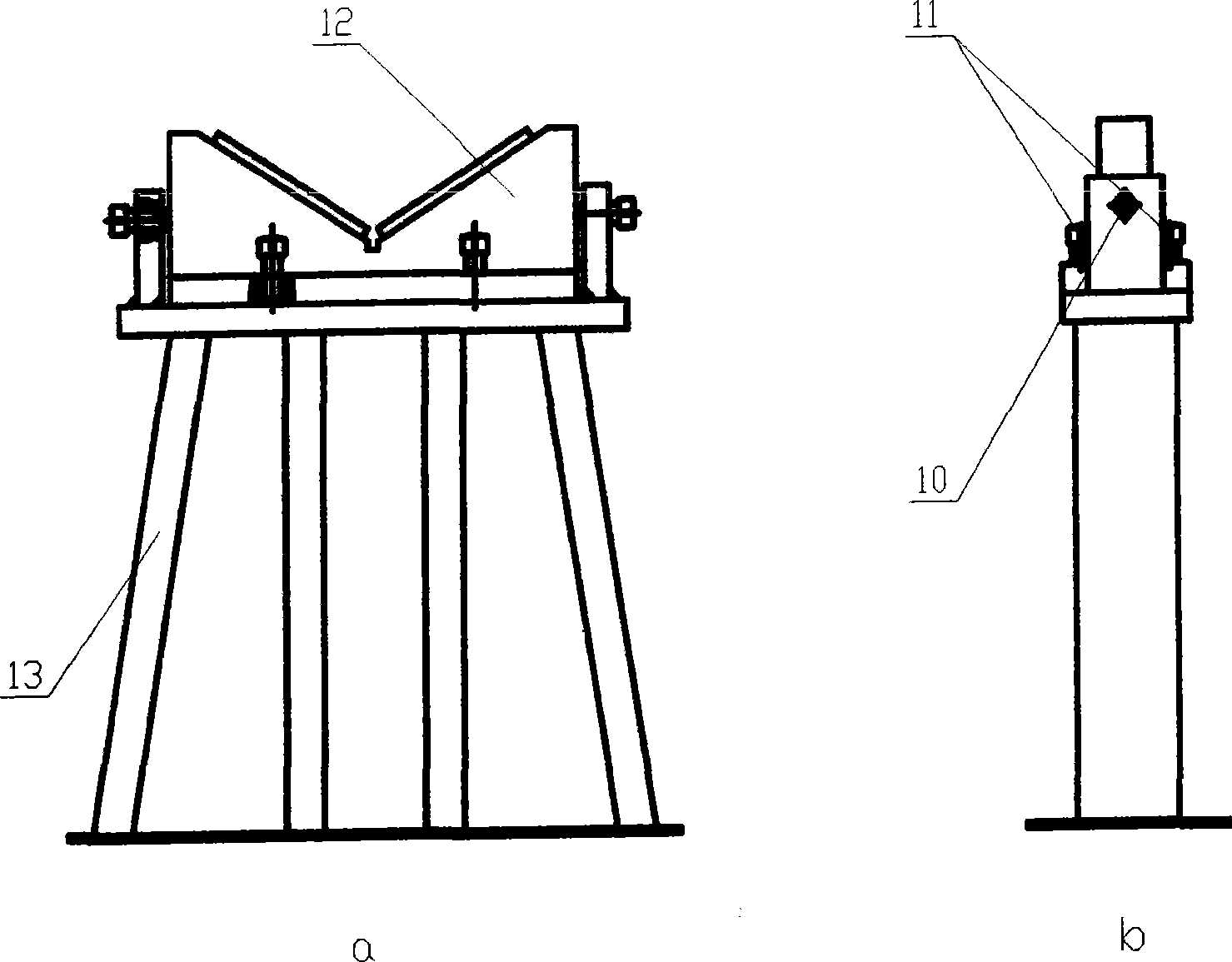

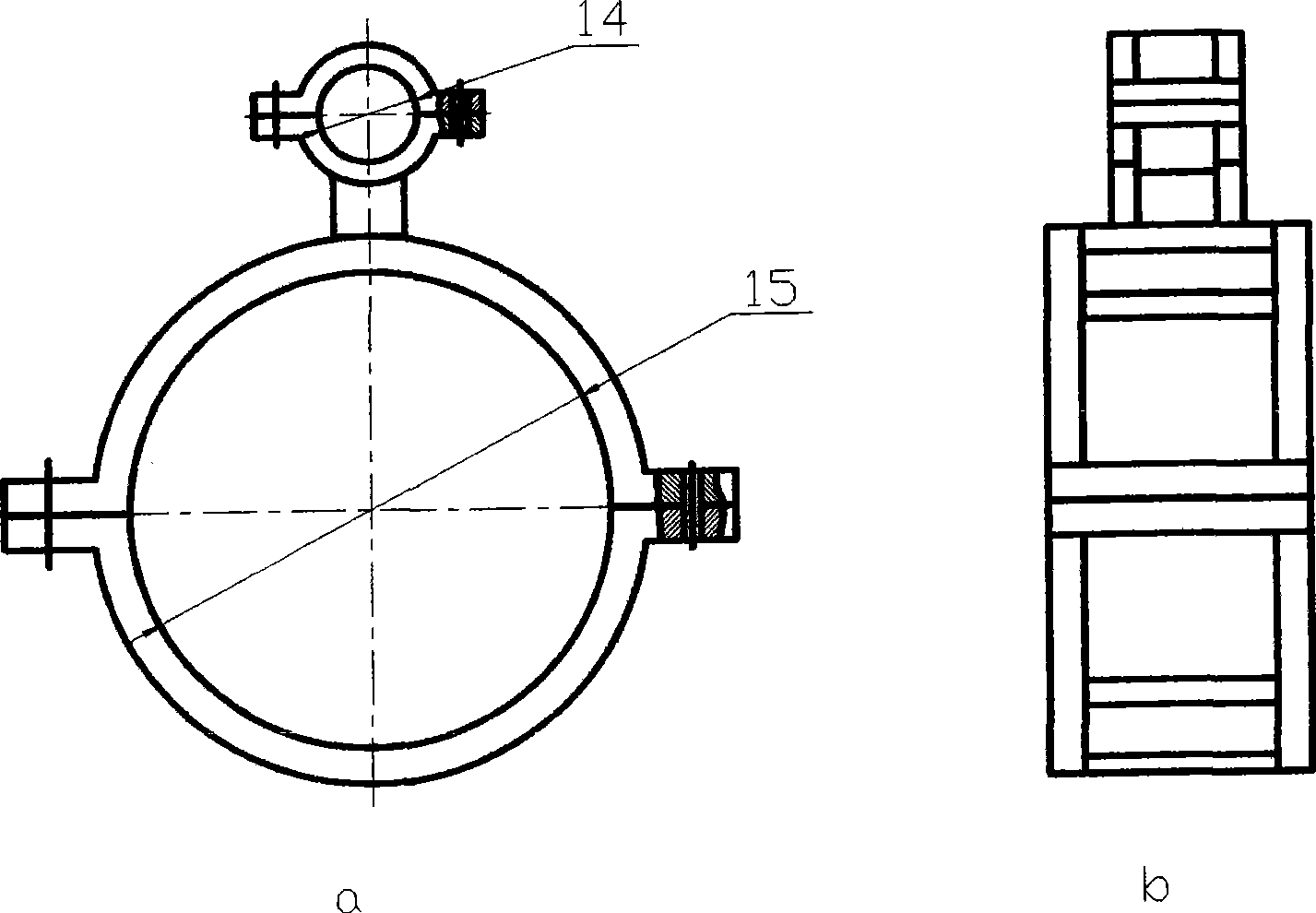

[0016] 1) First, drill and bore the flange holes of the propeller shaft 8 and the intermediate shaft 7 on a CNC boring and milling machine to a difference of 3-4 mm from the finish, and place four adjustable brackets 1 on a flat field according to the actual position of the bearing position ;

[0017] 2) Adjustable bracket 1 is covered with a cowhide pad, and lubricated with an appropriate amount of engine oil, and the propeller shaft 8 is hoisted onto the adjustable bracket 1 to prevent the surface of the finishing shaft from being scratched; use a spirit level to adjust the level, and hoist the intermediate shaft 7 to the adjustable bracket 1, make the intermediate shaft 7 stick to the two flanges of the propeller shaft 8, adjust the positions of the two shafts so that the two flanges are close to each other, and use the dial indicator to detect the upper busbar and the upper busbar of the propel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com