Two-sides arc-welding device based on welding wire diffluence and welding method thereof

An arc welding and welding wire technology, applied in arc welding equipment, electrode support devices, welding equipment, etc., can solve the problems of welding seam overburning and welding penetration, narrow welding parameter range, shallow arc welding penetration, etc., and achieve small welding deformation. , The effect of narrow heat shadow area and large weld penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

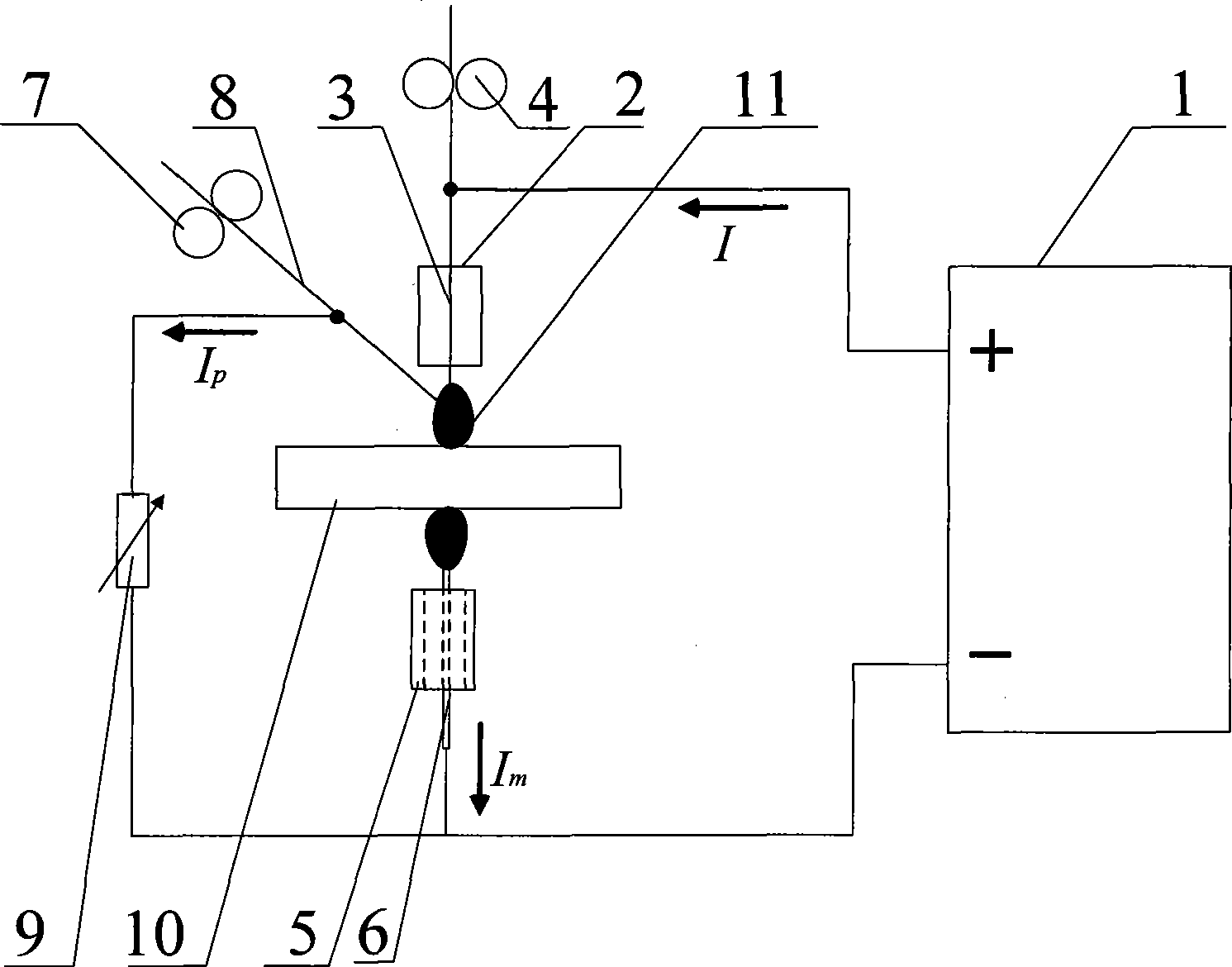

[0025] combine figure 1 , it is an embodiment of melting electrode-non-melting electrode double-sided arc welding based on welding wire shunting. This embodiment consists of welding power supply 1, melting electrode welding torch I2, welding wire 3, wire feeder 4, non-melting electrode welding torch II5, It consists of tungsten electrode 6, wire feeder 7, filler wire 8 and sliding rheostat 9, etc. It includes a melting pole welding torch I2, and the other is a non-melting pole welding gun II5. Before welding, the melting pole welding gun 2 and the non-melting pole welding gun 5 are symmetrically placed on the upper and lower sides of the workpiece 10 respectively, and the electric terminal of the melting pole welding gun I2 It is connected to the positive pole of the welding power source 1, and the non-melting electrode welding gun II5 is connected to the negative pole of the welding power source 1, and the filler wire 8 is sent into the arc 11 and the molten pool formed by th...

specific Embodiment approach 2

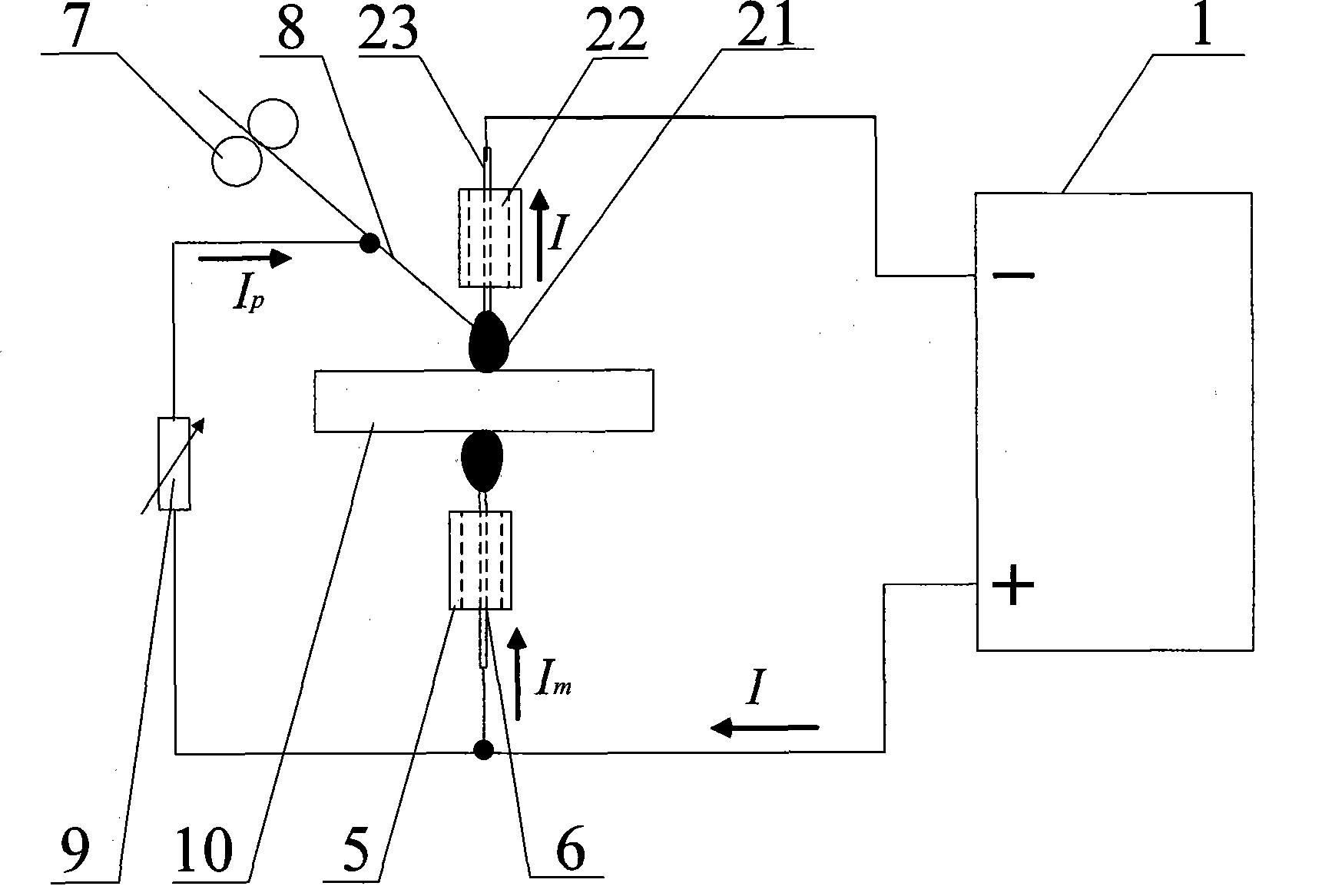

[0032] In conjunction with Fig. 3, it is the embodiment of non-melting pole-non-melting pole double-sided arc welding based on welding wire shunting. Pole 6, wire feeder 7, filler wire 8 and sliding rheostat 9 and so on. It includes two non-melting pole welding guns, i.e. non-melting pole welding gun I22 and non-melting pole welding gun II5. The electric terminal of the welding torch I22 is connected to the negative pole of the welding power source 1, the electric terminal of the non-melting electrode welding torch II5 is connected to the positive electrode of the welding power source 1, and the filling welding wire 8 is fed into the non-melting electrode welding torch I22 by the wire feeder 7. In the arc 21 or the molten pool, the filler wire 8 is connected to the positive pole of the welding power source 1 through the sliding rheostat 9, and plays the role of shunting and preheating the welding wire 8.

[0033] The welding steps of the non-melting pole-non-melting pole doub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com