Method for preparing niobium pentoxide nano stick

A niobium pentoxide and nanorod technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of complex reaction process and expensive equipment, and achieve the effect of simple and easy method and large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

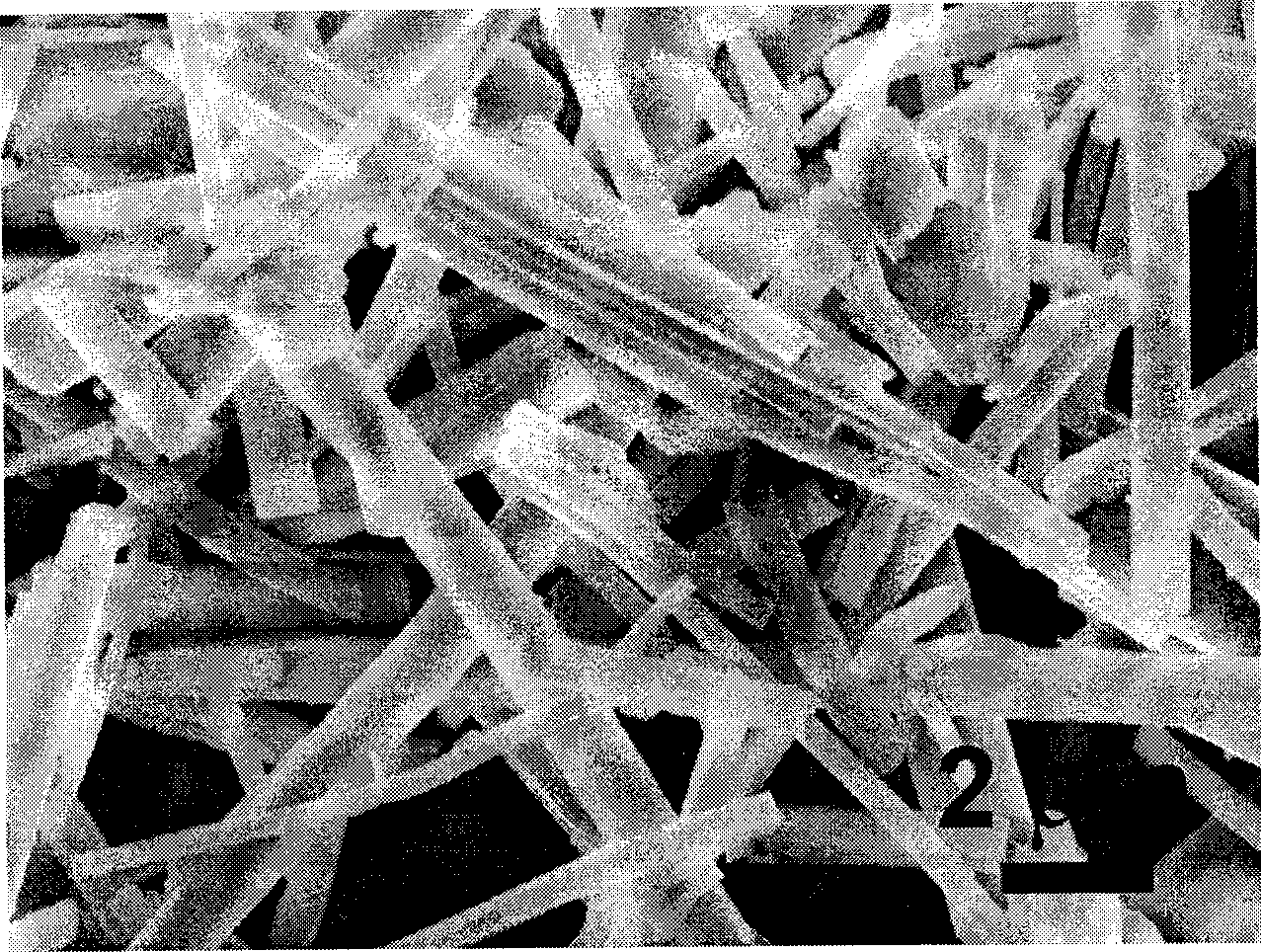

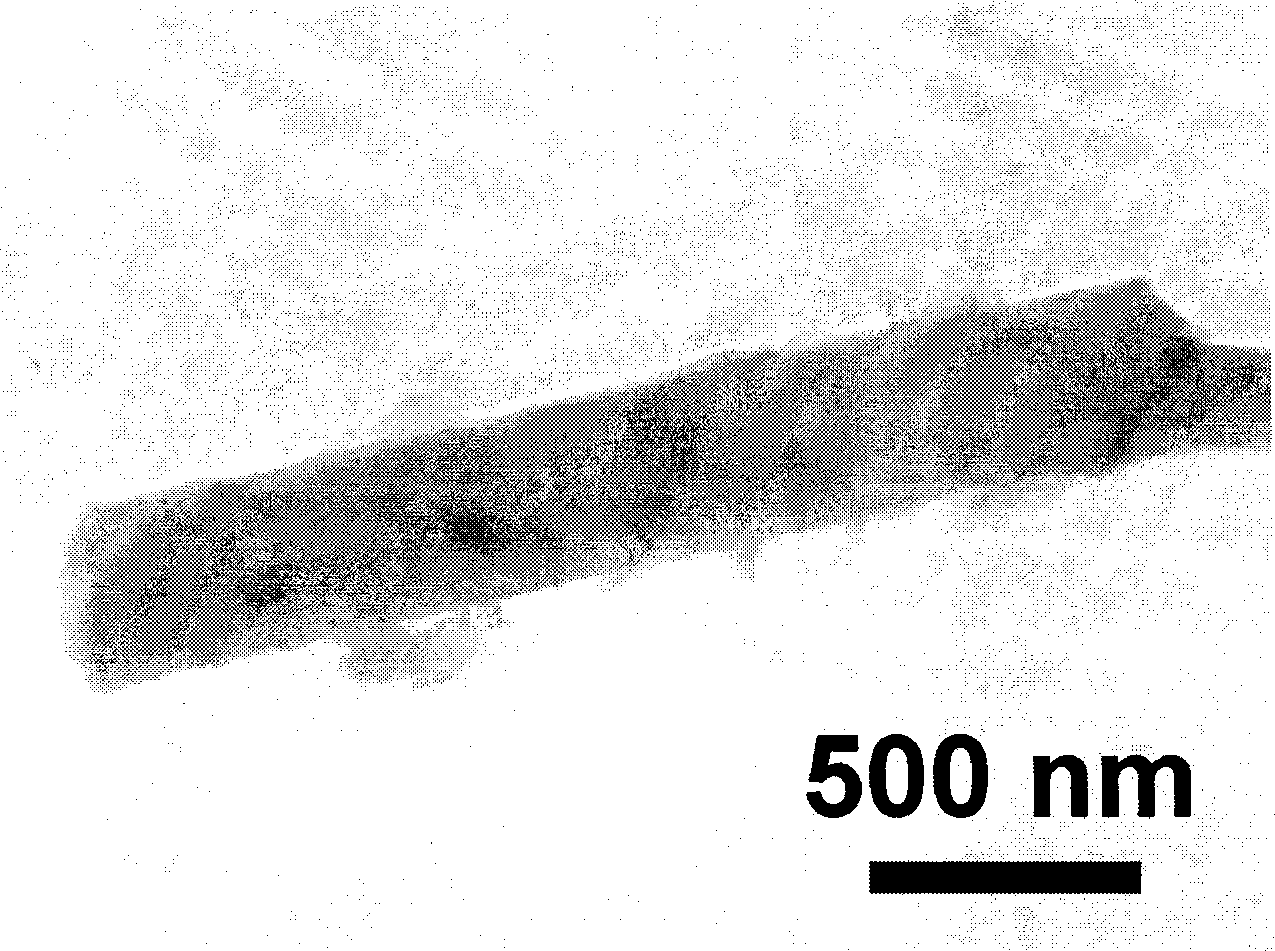

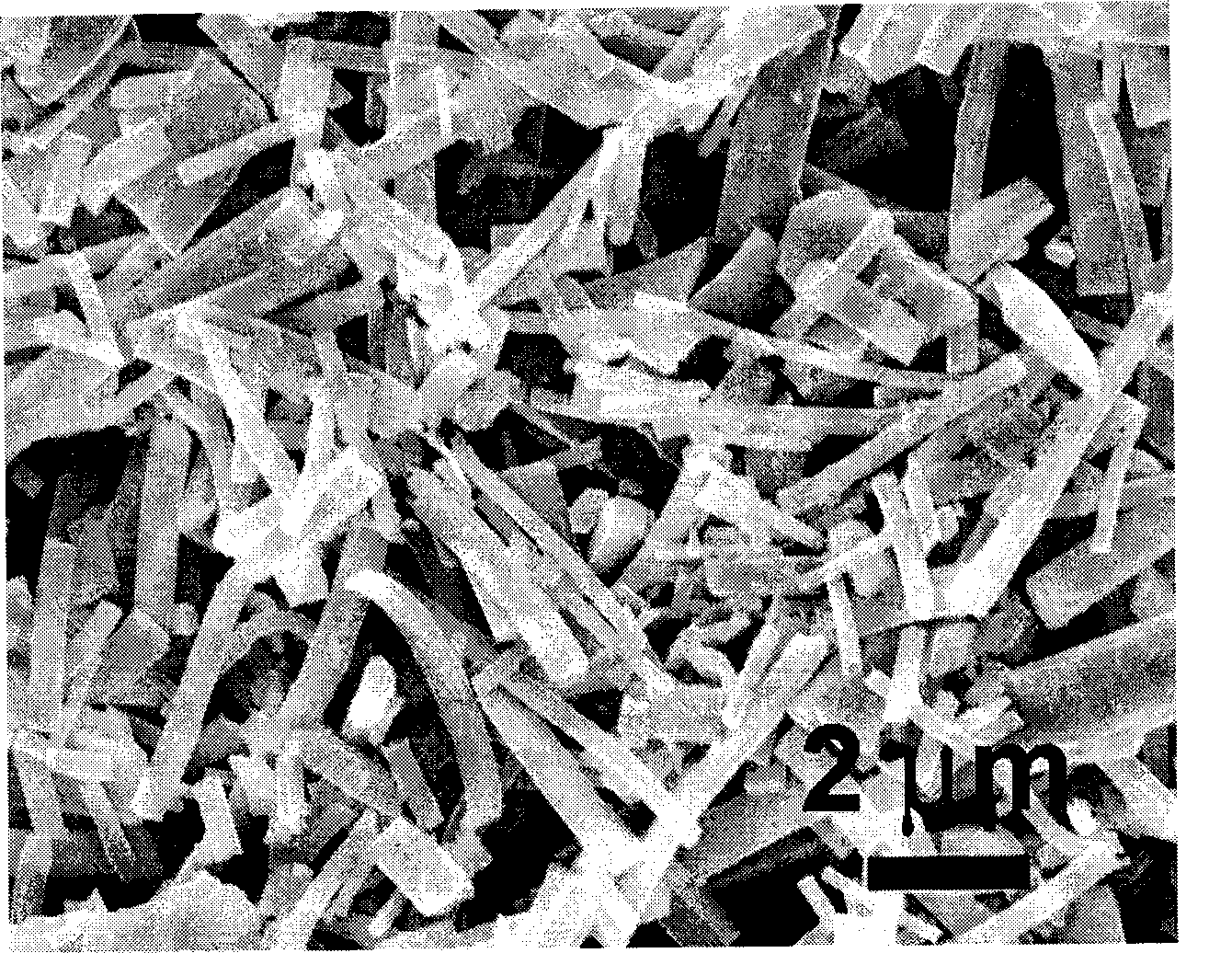

[0008] Embodiment 1: The preparation method of niobium pentoxide nanorods in this embodiment is as follows: 1. After mixing calcium niobate nanorods and hydrochloric acid with a concentration of 0.01~1mol / L according to the molar ratio of 1:10~20 Stir for 30 to 120 minutes, then centrifuge the obtained product and rinse it with deionized water for 3 to 5 times to obtain niobic acid nanorods; 2. Anneal the niobic acid nanorods in air at a temperature of 600 to 750°C for 1 to After 3 hours, niobium pentoxide nanorods were obtained.

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of hydrochloric acid in step 1 is 0.02-0.5 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 in that the concentration of hydrochloric acid in step 1 is 0.12-0.4 mol / L. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com