Trussed-beam steel beam reinforcing structure

A reinforced structure and truss-type technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems of high steel consumption and little improvement in bearing capacity, so as to improve bearing capacity and section moment of inertia I value , Reinforcement effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

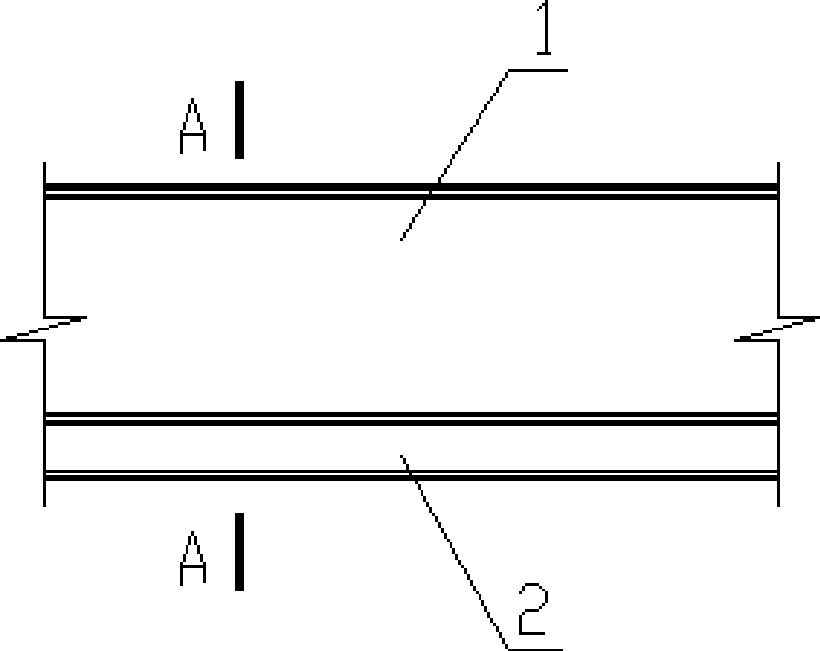

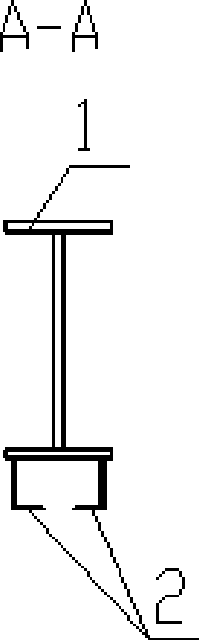

[0017] Embodiments of the present invention: when adopting the method of the present invention to reinforce existing steel beams, it can be carried out according to the following methods and steps:

[0018] First, determine the moment of inertia of the section to be increased by calculation, and pay attention to the net height of the bottom of the newly added truss 3 to meet the requirements of use. If not, the height of the newly added truss 3 can be adjusted to meet the requirements;

[0019] Second, according to the above calculation results, determine the cross-sectional size of the truss mid-web member 5, lower chord member 6 and upright column 7. The web member 5 and lower chord member 6 are connected by equilateral double-angle steels and connected by slabs 4. The center distance between slabs is 500mm. The thickness of the patch plate is 8mm, the specification of the angle steel should be determined according to the calculation, the thickness of the spliced gusset pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com