Product reflux extraction column

A technology for extraction towers and products, applied in the field of extraction towers, can solve problems such as poor operational stability and low product purity, and achieve the effects of reducing operational instability, reducing initial concentration, and improving the purity of extracted products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order that the present invention is described in further detail, below in conjunction with accompanying drawing, the present invention is described in further detail:

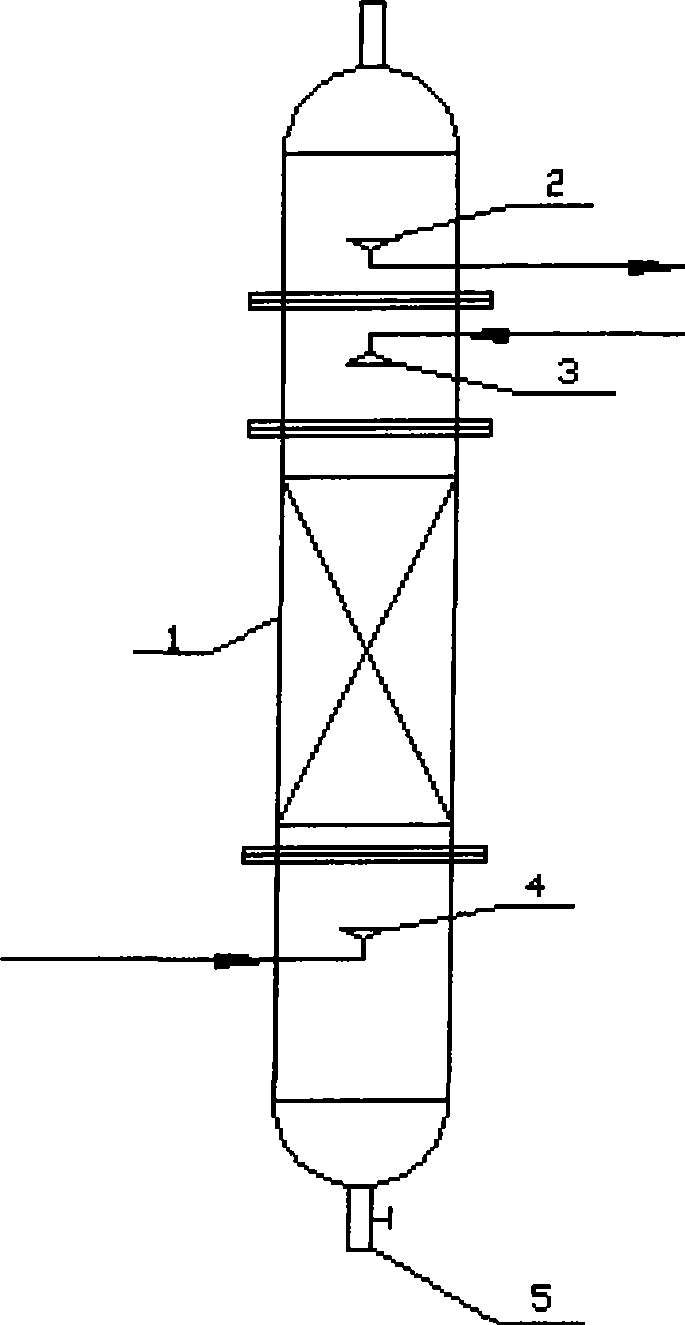

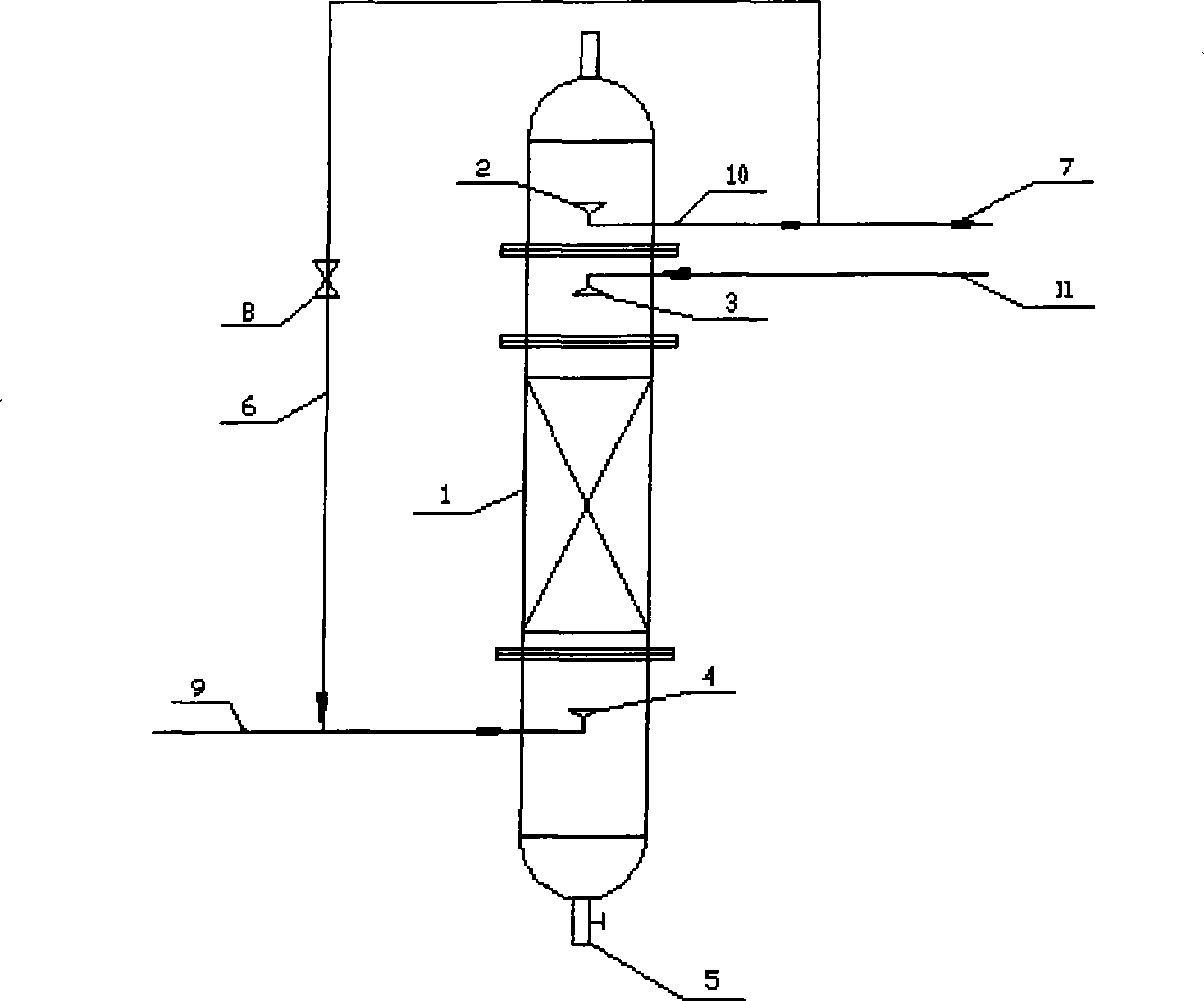

[0013] Now take the oil phase as the dispersed phase, the water phase as the continuous phase, and the oil phase to be extracted as an example, and the packing extraction tower with a tower diameter of 150 mm and a packing section height of 1200 mm is used to describe the present invention in detail, as image 3 As shown, the tower body from the top to the bottom of the tower is as follows: clarification section, with light phase outlet 2 inside; heavy phase inlet 3; extraction section 1, with several pieces of structured packing inside; settling section, with light phase distributor 4 inside And the liquid discharge port 5, the distributor adopts the shower head pressure type, and the liquid discharge port is located at the bottom of the tower. The light phase inlet pipeline is connected to the oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com