Electric machine control method and device in hybrid motor

A hybrid vehicle and motor control technology, applied in hybrid vehicles, electric vehicles, motors, etc., can solve problems such as system instability and unstable voltage regulator operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

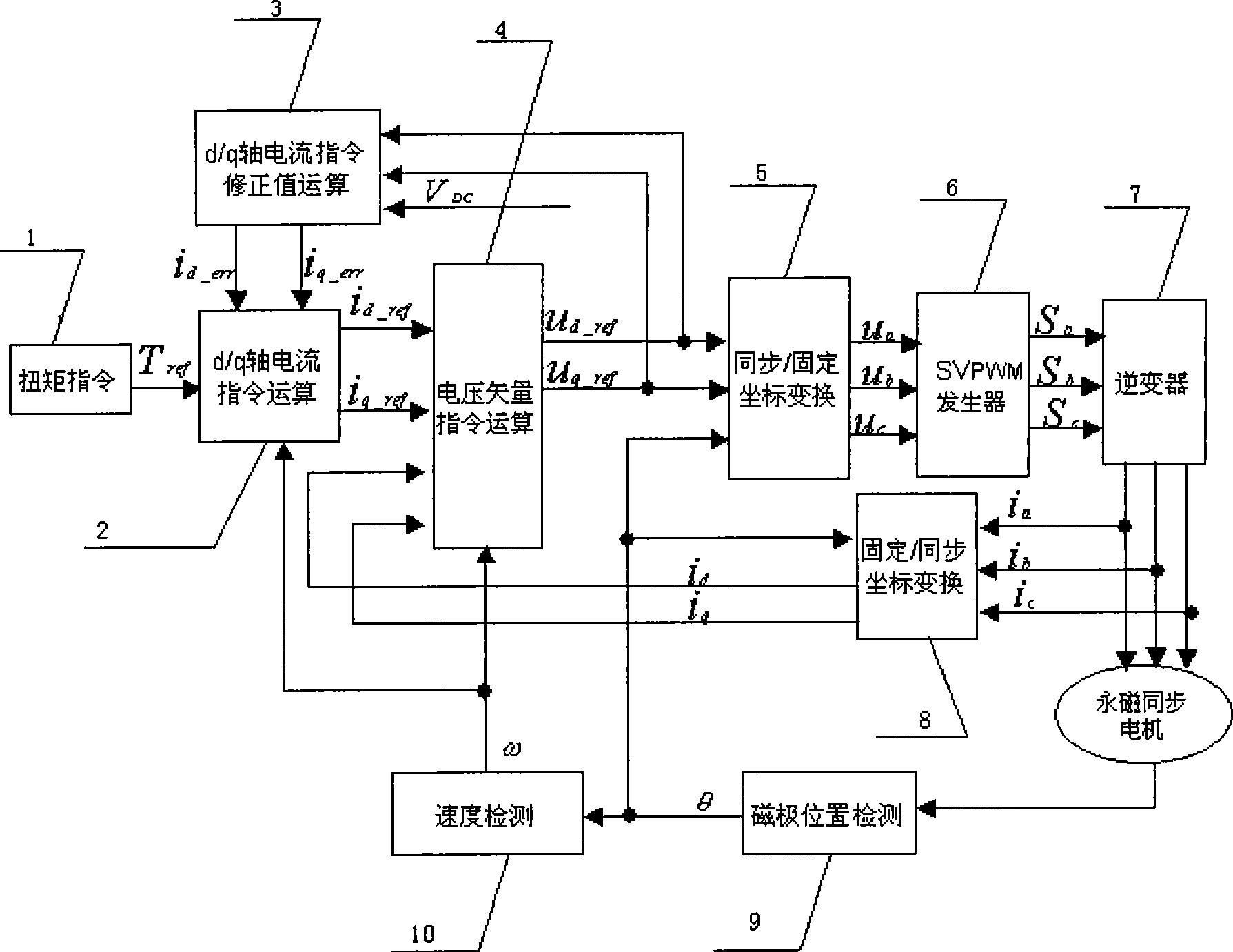

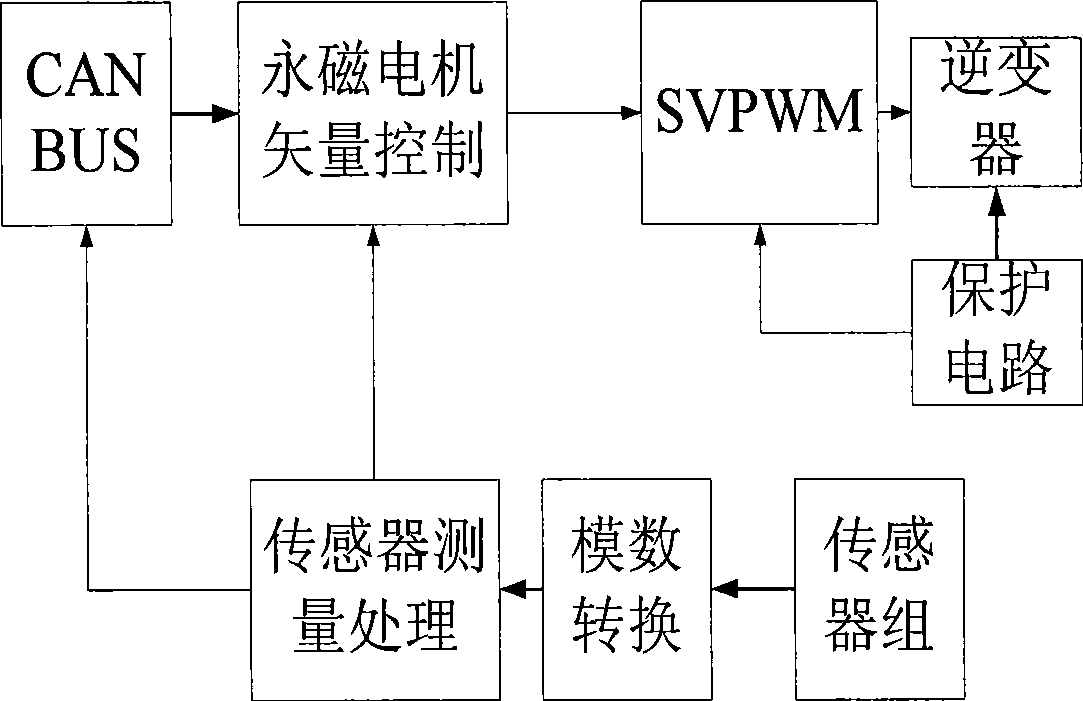

[0035] figure 1 It is a schematic block diagram of the permanent magnet synchronous motor control device in a hybrid electric vehicle. The motor adopts a vector control method, and different control methods are adopted for the motor according to the running state of the vehicle.

[0036] The main function of this motor in hybrid power is: to stop the engine when the car is stationary, and to start the engine when it needs to be started; to provide auxiliary torque for the engine to reduce the engine load during the running of the car; to be able to regenerate in other cases Braking can effectively charge the battery on the car. There are four modes of operation of the motor:

[0037] (1) Speed mode: According to the speed command of the vehicle controller, the motor is controlled to meet the speed requirement, and the engine is started to run.

[0038] (2) Torque mode: After successful startup, it operates in torque mode, providing auxiliary torque drive and regenerative b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com