Vehicle running monitoring system based on optical fibre grating

A fiber grating and vehicle operation technology, which is applied in transportation and packaging, railway car body parts, and optical devices to transmit sensing components, etc. Falling off or failure and other problems, to achieve the effect of reducing the use cost of the system, convenient installation and maintenance, and strong anti-electromagnetic interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

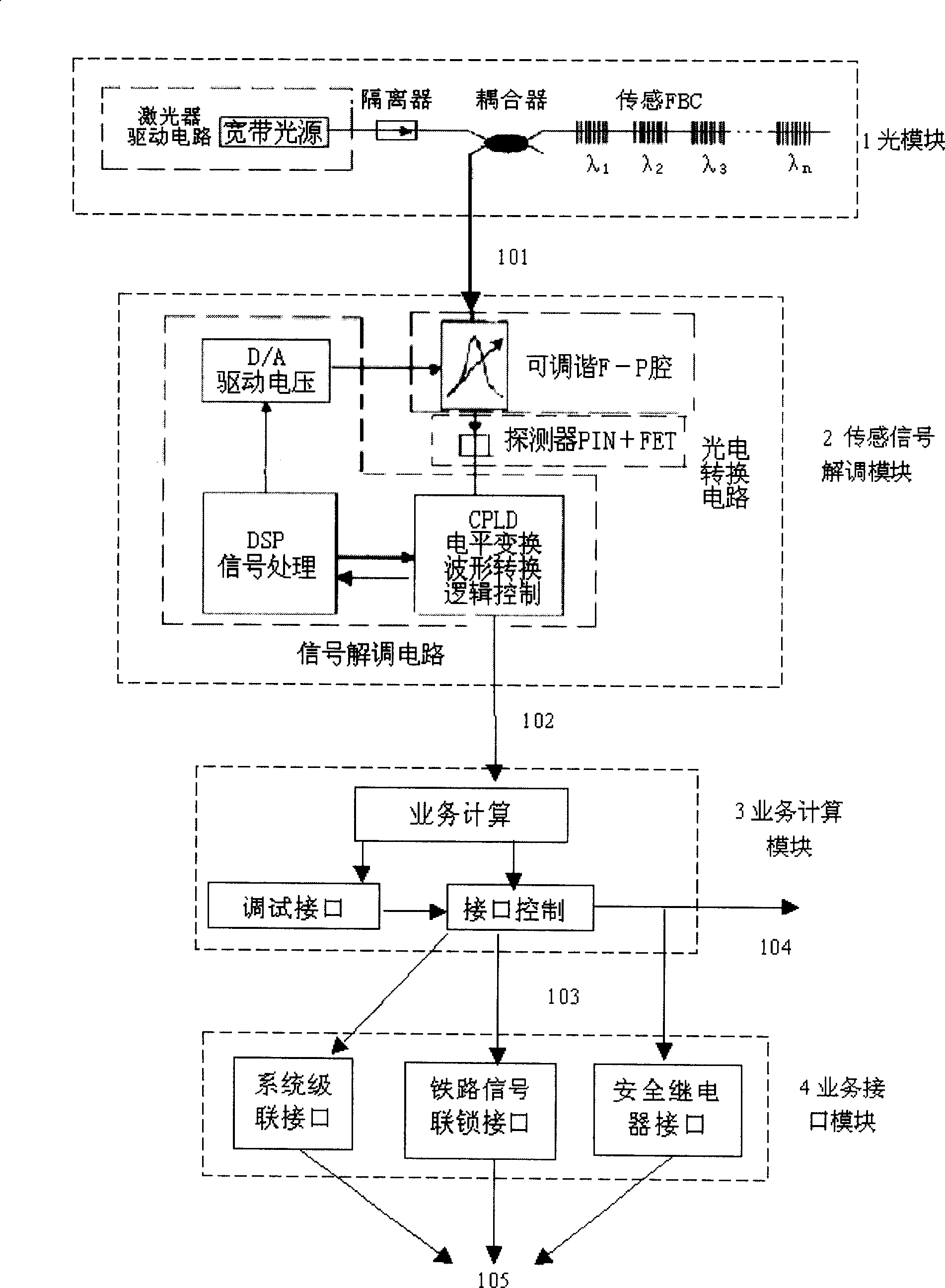

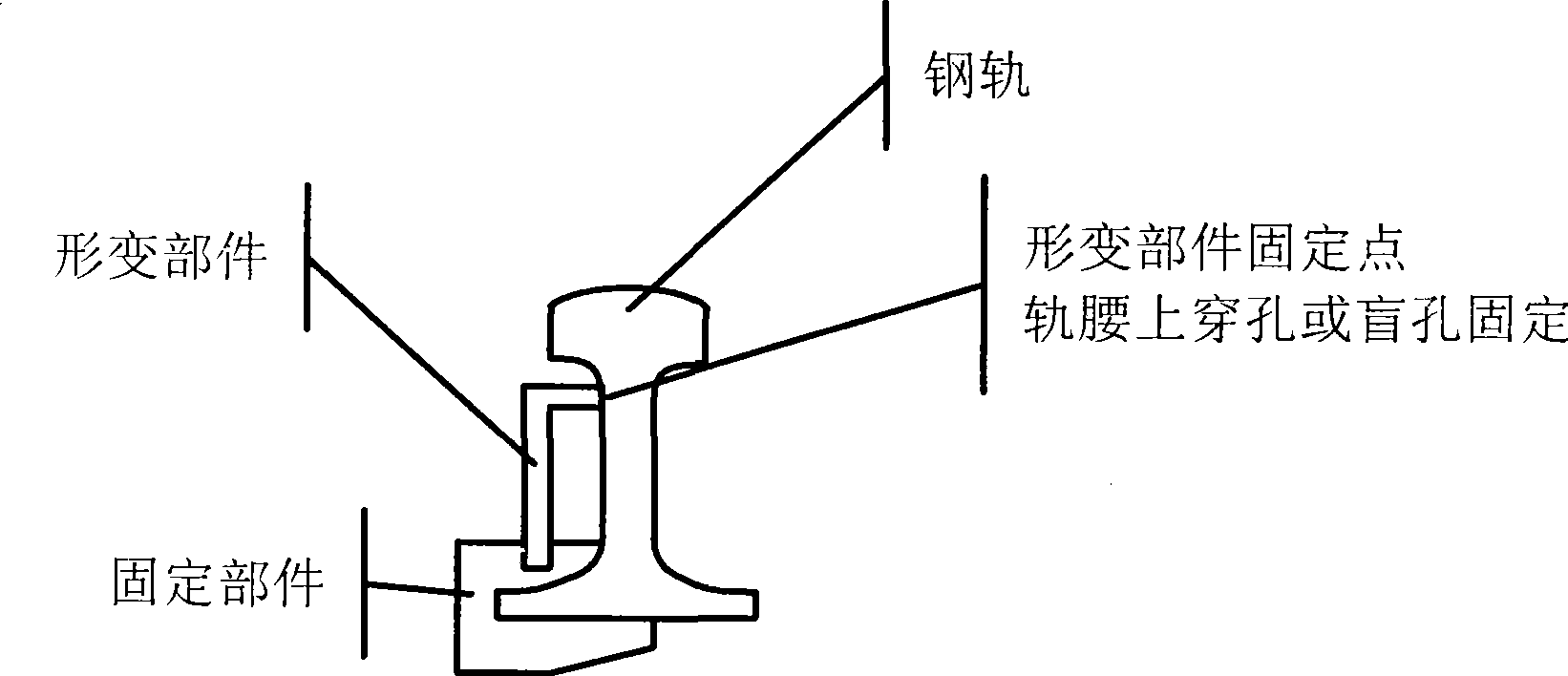

[0053] Embodiment 1: Track occupancy monitoring based on vehicle operation monitoring system

[0054] Track occupancy monitoring is a very important business in the field of railway signaling, which requires extremely high safety and reliability. For this kind of business application, the inventor thinks that for the security protection of the outdoor part, the optical ring protection and optical path redundancy can be used simultaneously or separately. The composition of the measurement interval requires at least two axle counting measurement points. For the specific arrangement of sensors in the measurement points and the axle counting calculation method, please refer to the "vehicle axle counting method based on rail deformation / stress parameters" filed by the inventor. The composition of the indoor subsystem is as follows: figure 1 As shown, among them, the sensing signal demodulation module 2 and the business computing components of the business computing module should a...

Embodiment 2

[0055] Embodiment 2: Realize hump length measurement based on vehicle operation monitoring system

[0056] In the hump grouping control signal, the free length data of the grouping line is very important for the safety of automatic and semi-automatic grouping operations. Traditional length measurement technology is based on traditional techniques such as track circuit impedance variation or radar length measurement. Utilizing the axle counting method provided in the "vehicle axle counting method based on rail deformation / stress parameters" filed by the inventor in another application, the hump length measurement using the fiber grating sensor can be realized.

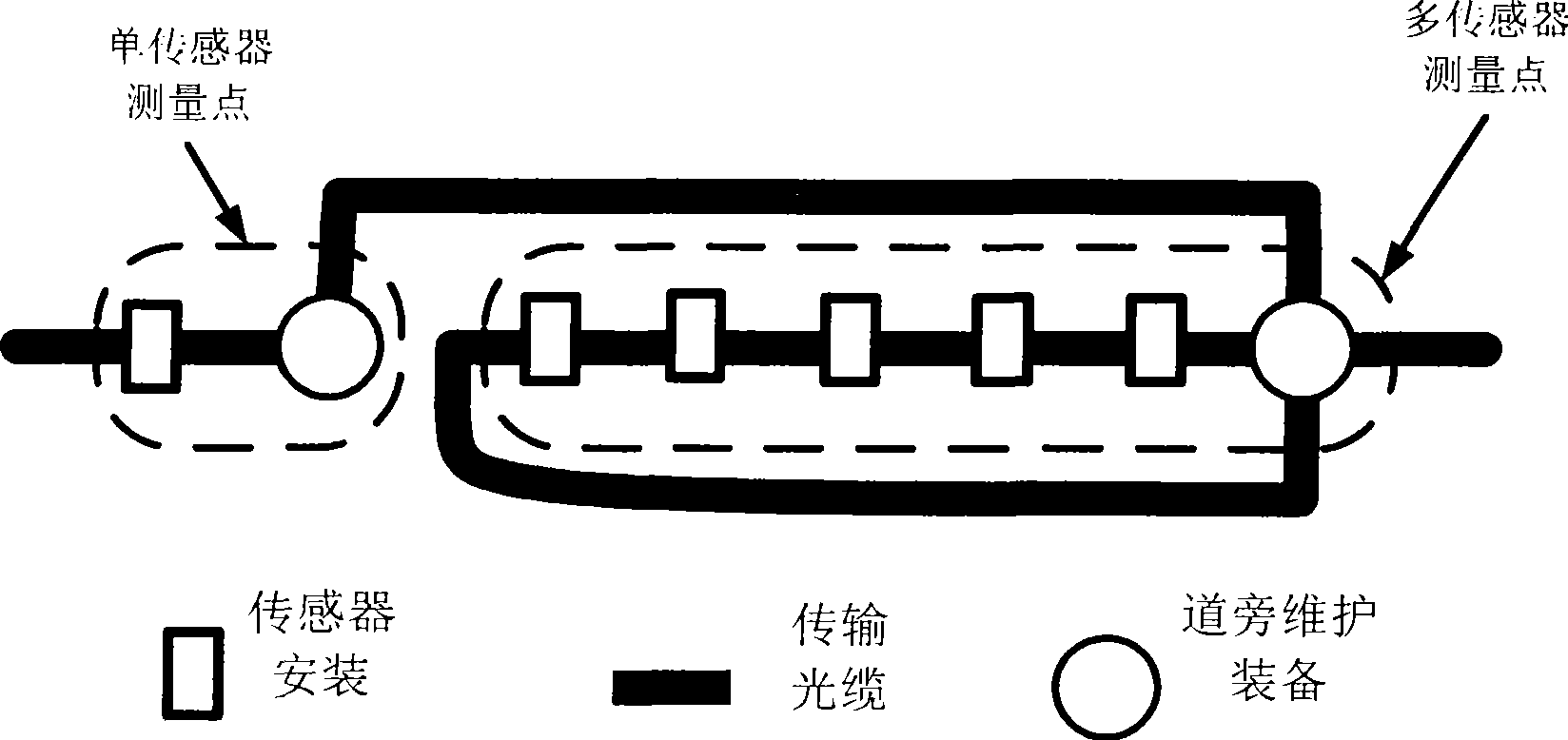

[0057] The axle counting point arrangement for hump length measurement is very similar to Image 6 or Figure 7 In the way shown, the measuring points here are the axle counting measuring points; the adjacent railway line is the marshalling line; the interval between two axle counting measuring points on the same mars...

Embodiment 3

[0059] Embodiment 3: Realize train speed measurement based on vehicle operation monitoring system

[0060] In this embodiment, the composition of the indoor subsystem adopts figure 1In the structure shown, the interface of the business interface module 4 can be determined according to the needs of the business organization. The layout and specific calculation method of the outdoor subsystem can refer to the "Vehicle Speed Measurement Method Based on Rail Deformation / Stress Parameters" filed by the inventor. To put it simply, when using a single measurement point for speed measurement, firstly arrange the deformation / stress sensor on the measurement point, measure the time interval for each wheel set of the train passing through the measurement point, and obtain the distance between each wheel set by comparing the car model and the bogie model. The length interval between them, divide the corresponding length interval by the time interval to get the speed of the train passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com