Amine catalysts suitable for producing flexible polyurethane foams having low emissions and being recatalysis stable

A technology of polyurethane foam and flexible polyurethane, which is applied in the field of amine catalysts for preparing low-emission, re-catalyzed and stable flexible polyurethane foam, can solve the problem of polyurethane foam damage and the inability of flexible polyurethane foam to have flammability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

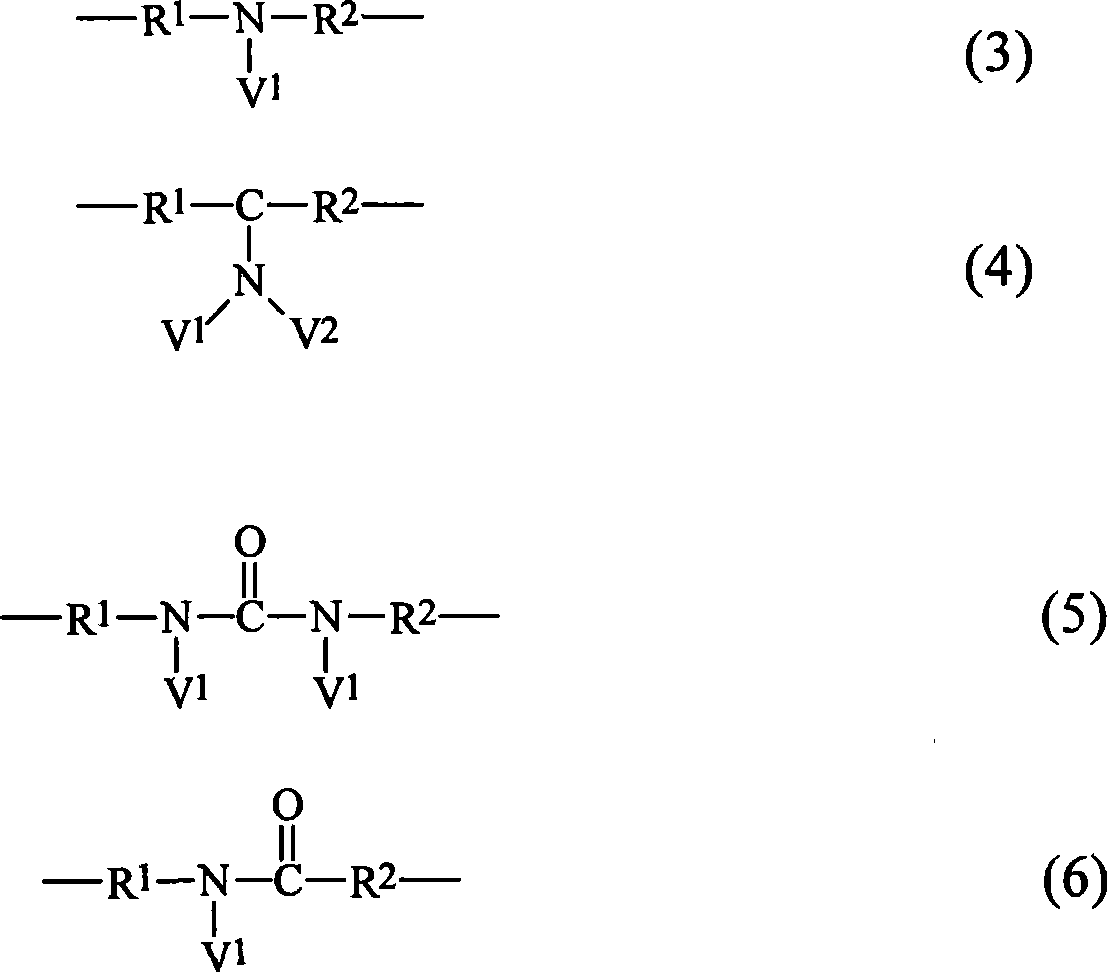

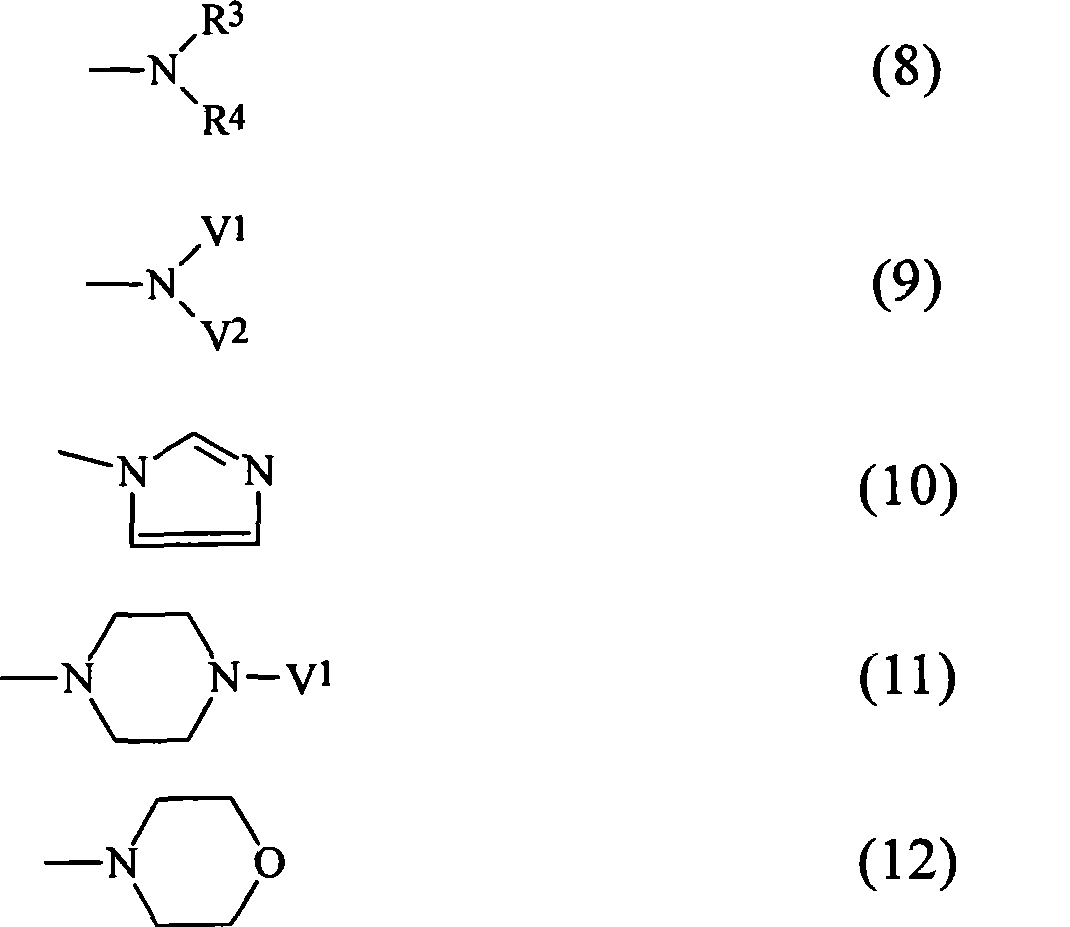

Method used

Image

Examples

preparation example Construction

[0147] Preparation of flexible polyurethane foam

[0148] 300 g of polyol were used for foaming; the other components of the formulation were scaled accordingly. Here, for example, 1.0 part of a certain component means 1 g of this substance per 100 g of polyol.

[0149] For foaming, the polyol, water, catalyst combination (=amine catalyst and organotin compound according to the invention) and silicone stabilizer are thoroughly mixed by stirring. After adding the isocyanate, the mixture was stirred with a stirrer at 3000 rpm for 7 seconds and poured into a paper-lined wooden box (bottom area 27 cm x 27 cm). Foams were thus produced which were subjected to the use tests described below.

[0150] use test

[0151] Physical Properties of Flexible Polyurethane Foam

[0152] The prepared flexible polyurethane foam was evaluated according to the following physical properties:

[0153] a) Settling of the bubble after the end of the rise phase

[0154] b) Foam density (FD)

[01...

Embodiment 1

[0186]

[0187] *1 = CP 3322, available from Dow Chemical; this is a polyether triol with an OH number of 47.

[0188] *2 = BF2370, available from Evonik Goldschmidt GmbH; this is a polysiloxane-polyoxyalkylene block copolymer used as a foam stabilizer in the preparation of slab and molded flexible polyurethane foams.

[0189] *3 = 29, available from Evonik Goldschmidt GmbH; this is the tin(II) salt of ethylhexanoic acid.

[0190] The table below shows the types of amines and the foaming results.

[0191]

[0192] * = back pressure in mm of water

[0193]

[0194] Diethylaminoethoxyethanolamine is better than An important advantage of DMEE is that it does not promote recatalysis.

Embodiment 2

[0196] Foaming Results - Scattered

[0197] In order to examine the effect of the amine catalysts diethylaminoethoxyethanol and dimethylaminoethoxyethanol on foam emission, a formulation comprising the catalyst combination of the invention together with a low emission polyol was selected.

[0198]

[0199] *4 =Arcol It is available from Bayer AG; this is a low emission polyether triol

[0200] *5 = EF, available from Evonik Goldschmidt GmbH; this is tin ricinoleate.

[0201] The emission behavior of the above-mentioned foams was investigated according to the Daimler-Chrysler test method BP VWT 709 VOC measurement (30 minutes at 90° C.).

[0202] and get the following result:

[0203]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com