Working fluid phase changing enthalpy difference sea water temperature difference power machine

A technology of phase change enthalpy and working medium, which is applied in the direction of mechanical power generation mechanisms, machines/engines, mechanical equipment, etc., and can solve problems such as difficult to use, complex formulas, and complex thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

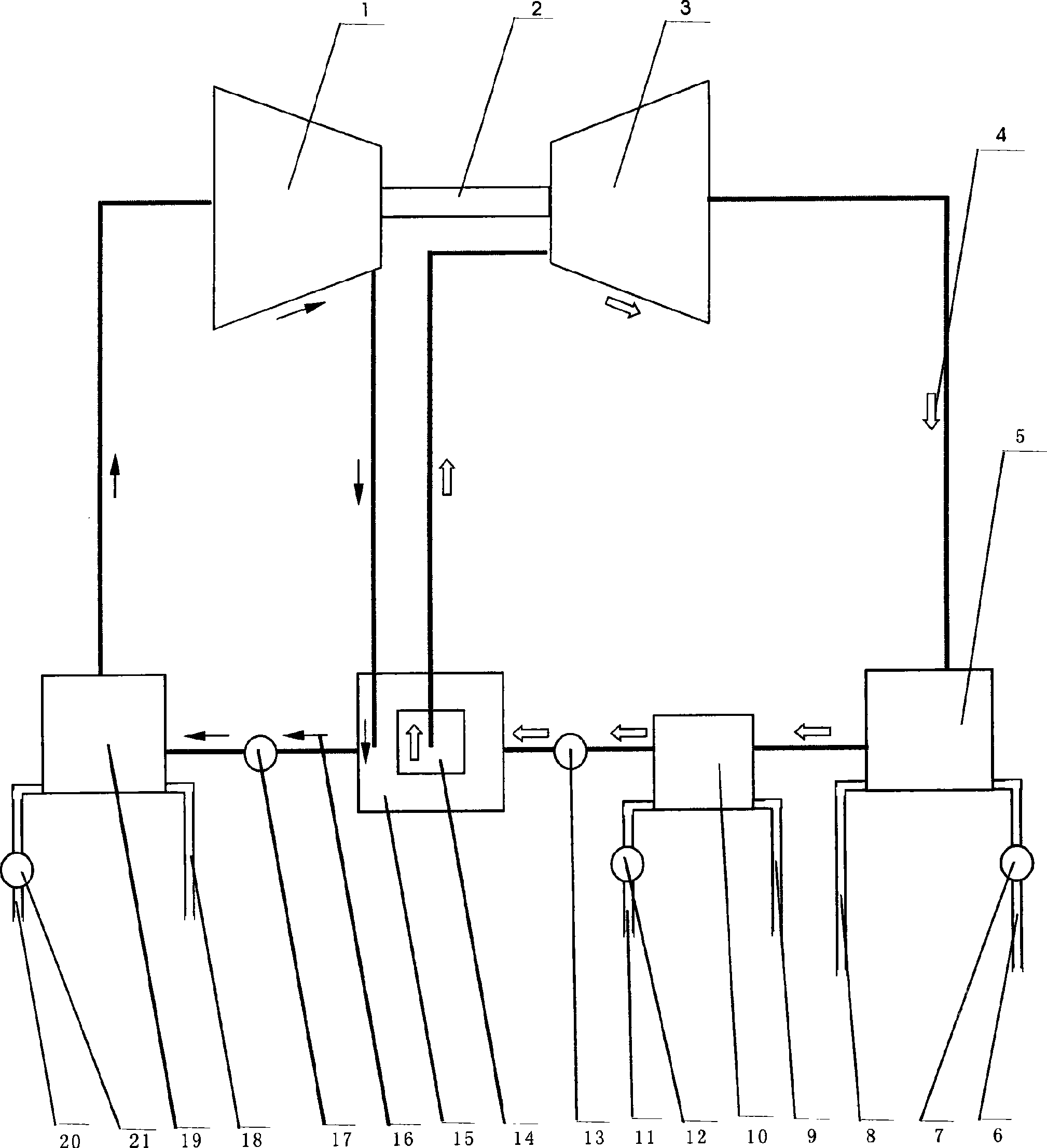

[0020] Embodiments of the present invention are: the high-speed centrifugal compressor [1], the steam turbine [3] are connected and fixed to a main shaft [2], and the high-speed centrifugal compressor [1] and the outer layer of the counter-flow heat exchanger are connected in sequence [15], infusion pump [17], and evaporator [19] are connected into a closed system, and the steam turbine [3], condenser [5], heater [10], infusion pump [13], counterflow heat The inner layer of the exchanger [14] is connected into another closed system. The counterflow heat exchanger is composed of inner and outer layers, the inner layer of the counterflow heat exchanger [14] and the outer layer of the counterflow heat exchanger [15]. The middle of the inner and outer layers is The metal wall with good thermal conductivity, the inner layer of the counter-flow heat exchanger [14] and the outer layer of the counter-flow heat exchanger [15], the circulating flow direction of the working fluid in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com