Full-equilibrium single cylinder diesel

A diesel engine and balance technology, applied in the direction of pressure lubrication of lubricating pump, inertia force compensation, lubrication of valve accessories, etc., can solve the problem of second-order reciprocating inertia force balance, single-cylinder diesel engine has large vibration and noise, and affects users. Comfort and other issues, to achieve the effect of compact structure, improved manufacturability, and reduced vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

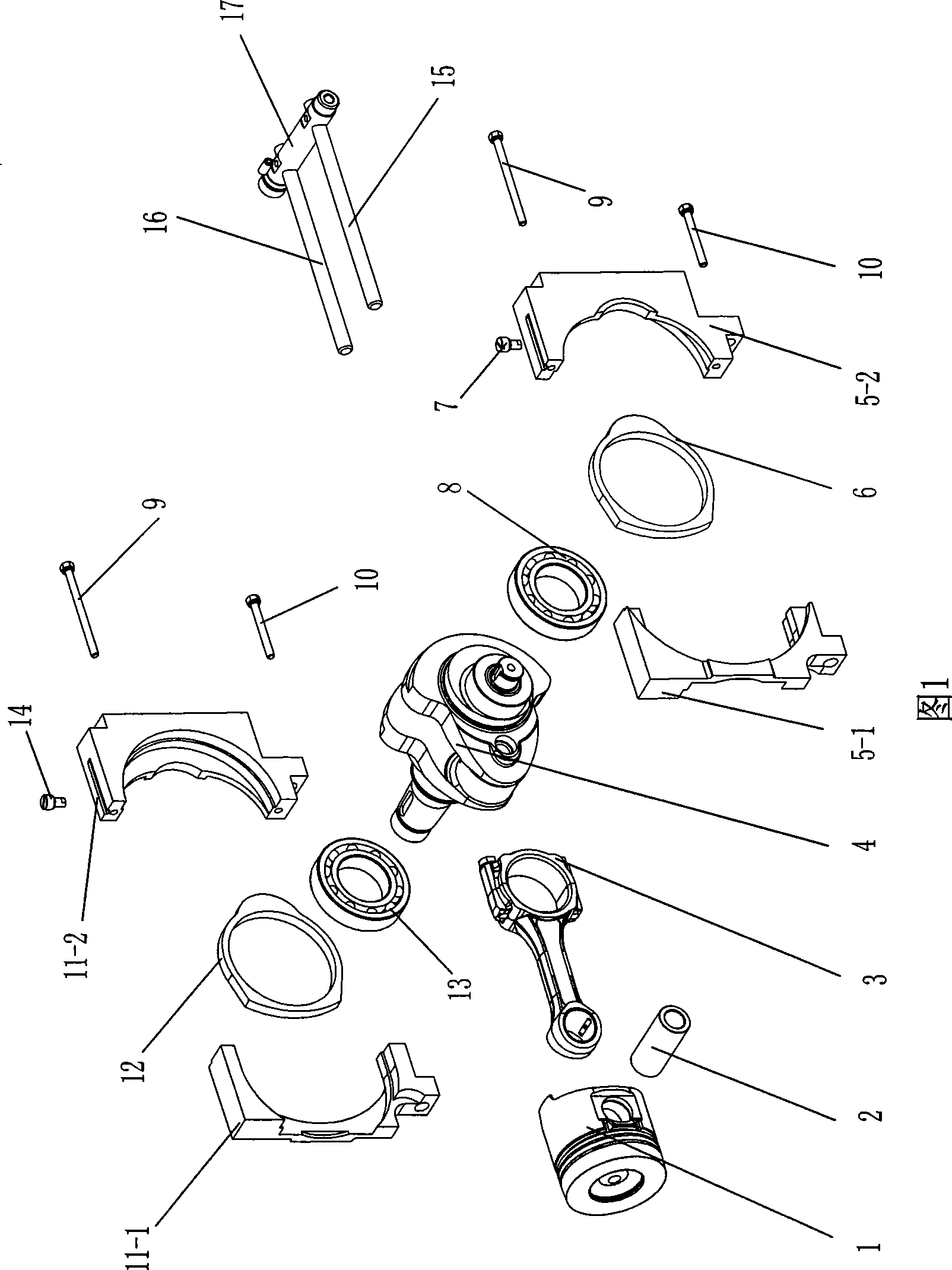

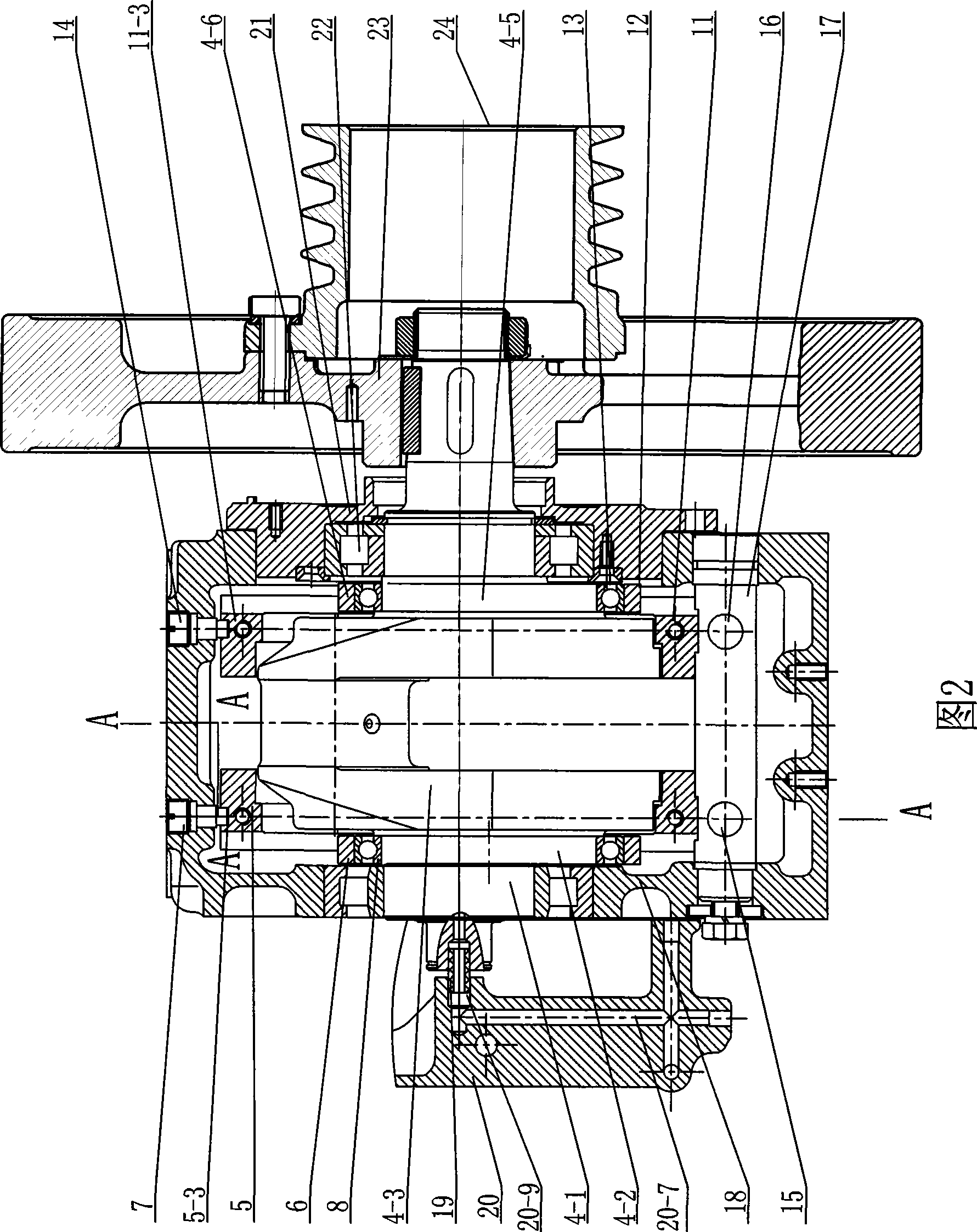

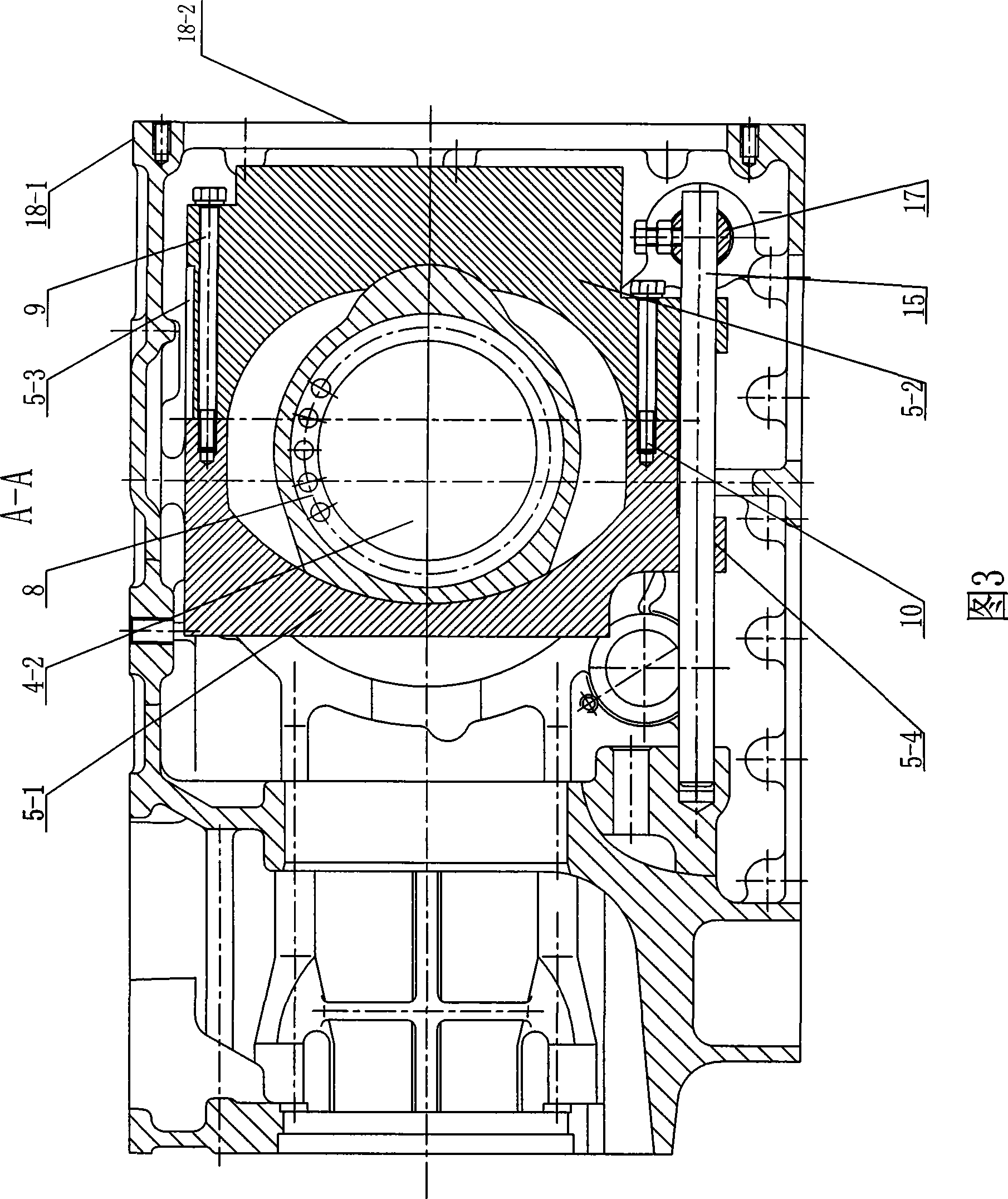

[0021] The fully balanced single-cylinder diesel engine of the present invention includes a body 18 and a crank connecting rod mechanism, as shown in FIGS. -6 are symmetrically provided with a front eccentric journal 4-2 and a rear eccentric journal 4-5, and the front main journal 4-1 and the rear main journal 4-6 of the crankshaft 4 are installed on the body 18 and the rear main journal 4-6 through two main bearings 22 respectively. On the bearing cover 21, the flywheel 23 and the belt pulley 24 are installed on the crank 4-3, the distance from the right end surface 18-2 of the body 18 to the central axis of the crankshaft is 160-170 mm, and the middle right part of the top wall 18-1 of the body is closed. There are reinforcing ribs on the closed plate to improve the mechanical performance of the body. The big end of the connecting rod 3 is connected with the crank 4-3, and the small end of the connecting rod 3 is connected with the piston 1 through the piston pin 2, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com