Iron member detecting method and device of constant magnetic deironing device by sound wave

An acoustic wave detection device and acoustic wave detection technology are applied in chemical instruments and methods, analysis of solids using sonic/ultrasonic/infrasonic waves, magnetic separation, etc. Simple, extended service life, low mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

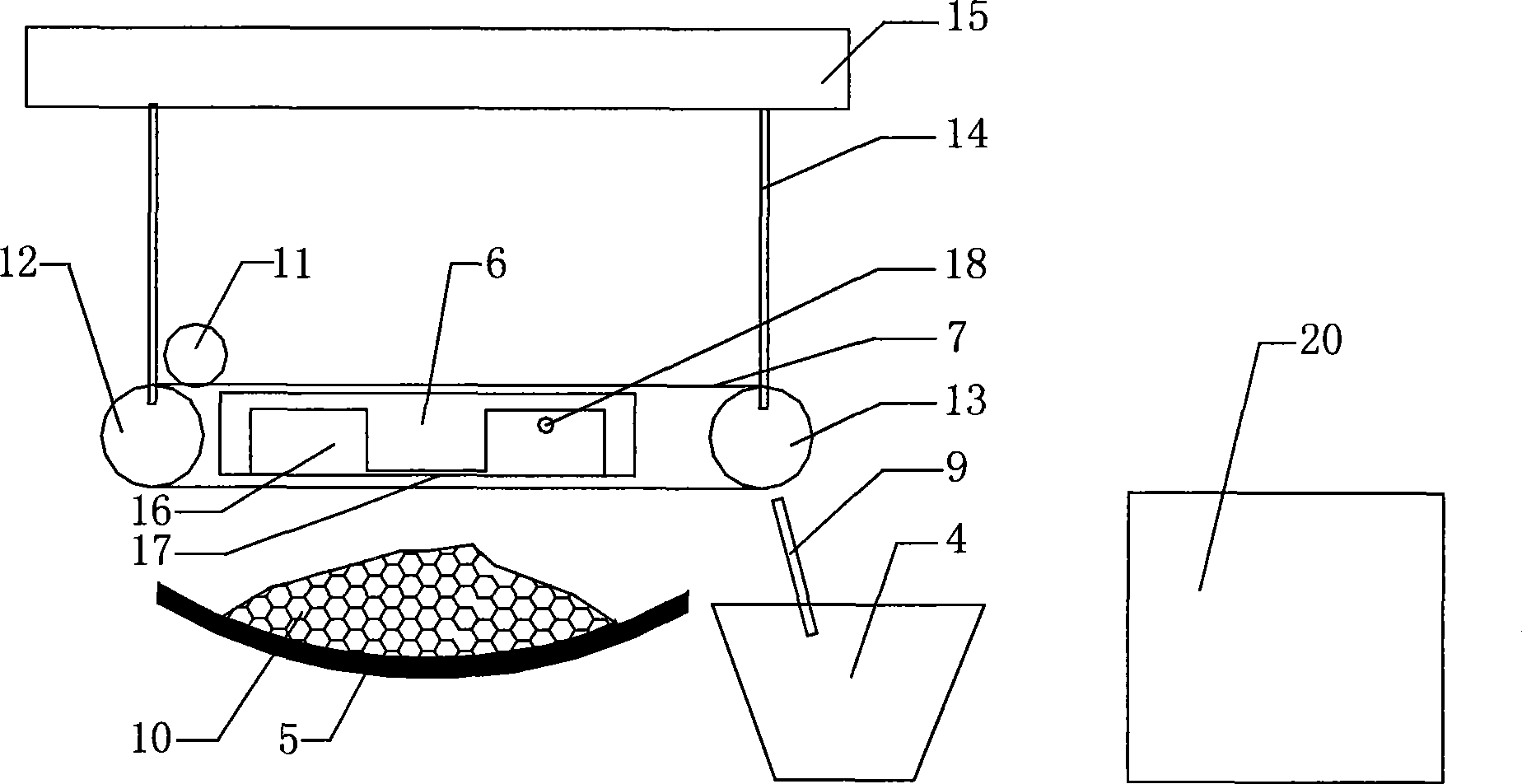

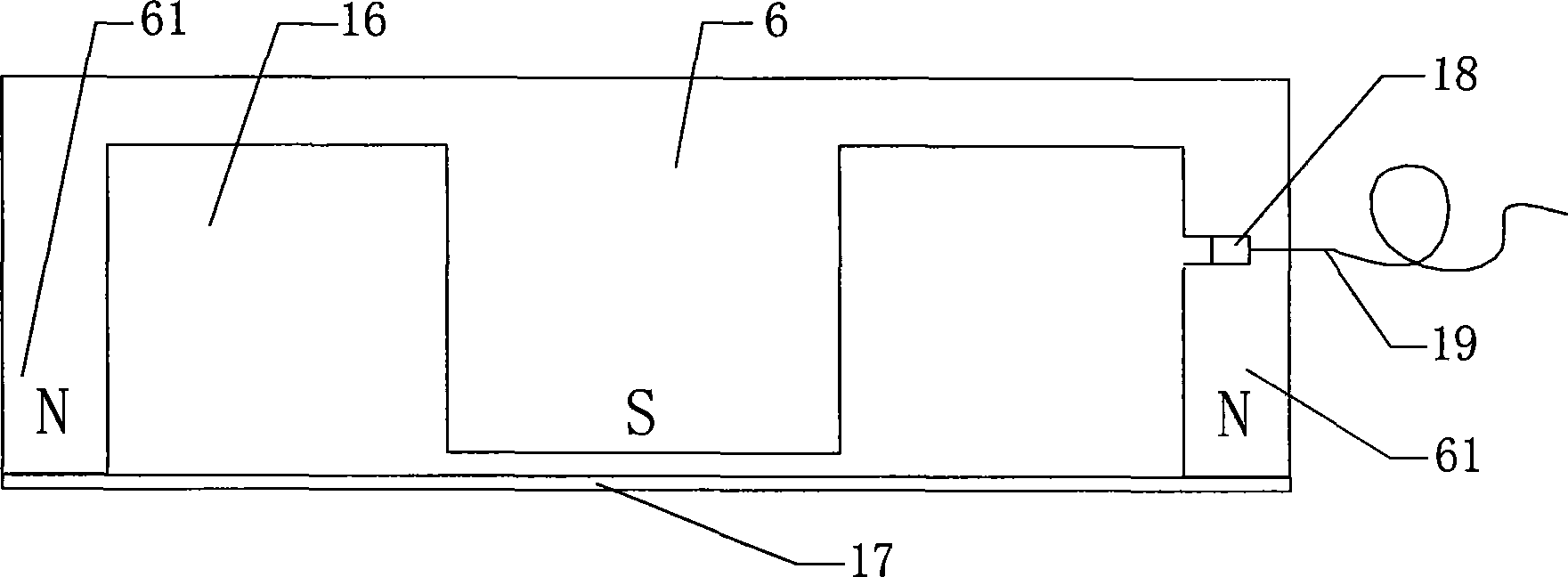

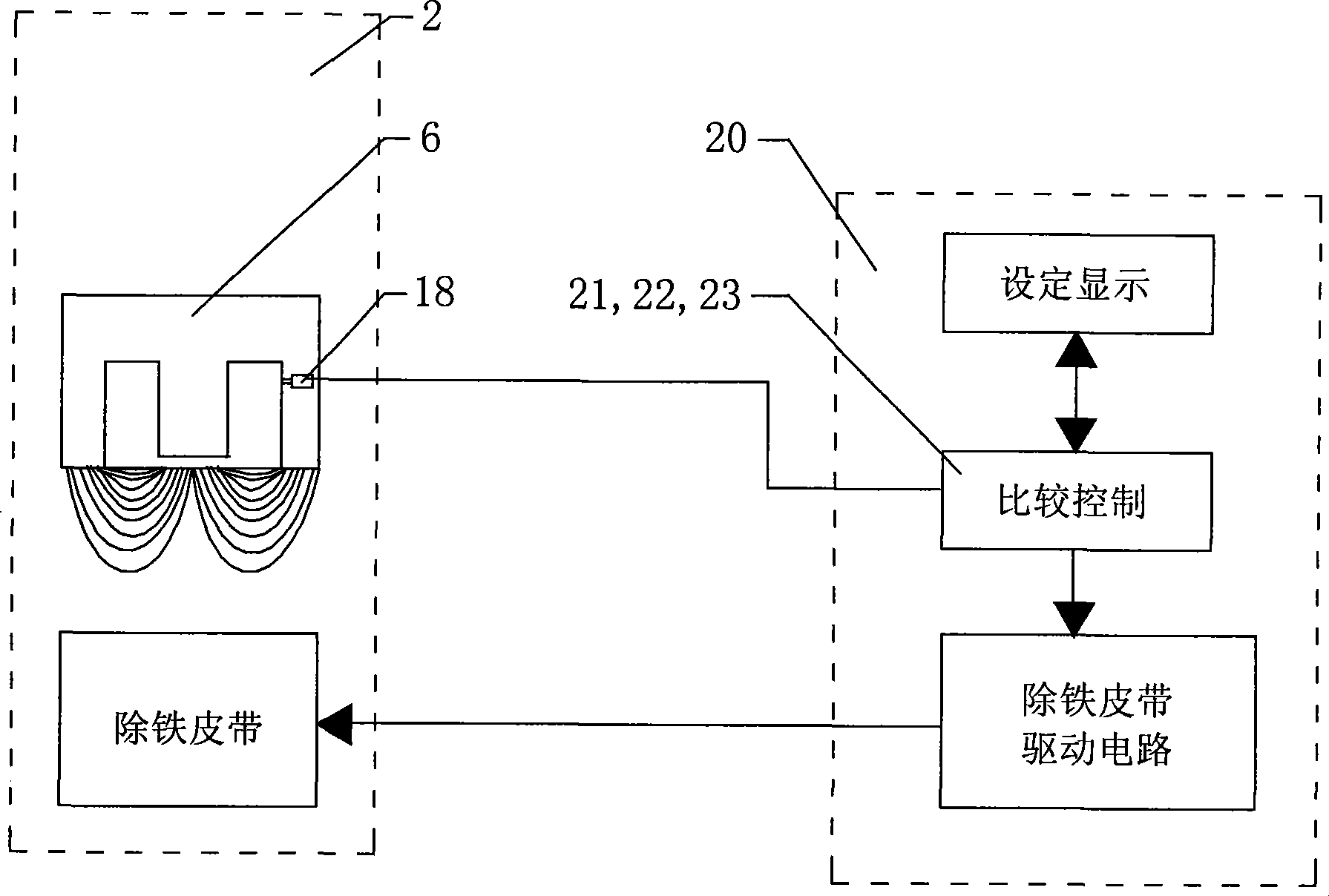

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , a constant magnetic iron remover adopts a device for detecting iron parts by sound waves, mainly consisting of an iron remover control box (controller) 20, a belt type constant magnetic iron remover 2 with sound wave detection, and a discarded iron hopper 4. Three parts Equipment composition. The belt-type constant magnetic iron remover 2 with acoustic wave detection includes a constant magnet 6, a non-magnetic separator 17, an acoustic wave detection device 18, a circular iron removal belt 7, an iron removal belt drive motor 11, an iron removal belt drive roller 12, an iron removal belt Iron belt support roller 13.

[0028] Constant magnet 6 is made up of middle magnet and surrounding constant magnet yoke 61, and constant magnet yoke 61 is a magnetizer, as iron plate, forms constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com