Heat treatment method and heat treatment apparatus

A heat treatment method and technology of a heat treatment device are applied in the field of ensuring uniformity of processing, which can solve the problem of difficulty in increasing the number of mounted blocks, and achieve the effects of enhancing uniformity of processing, increasing spacing and ensuring the number of mounted blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

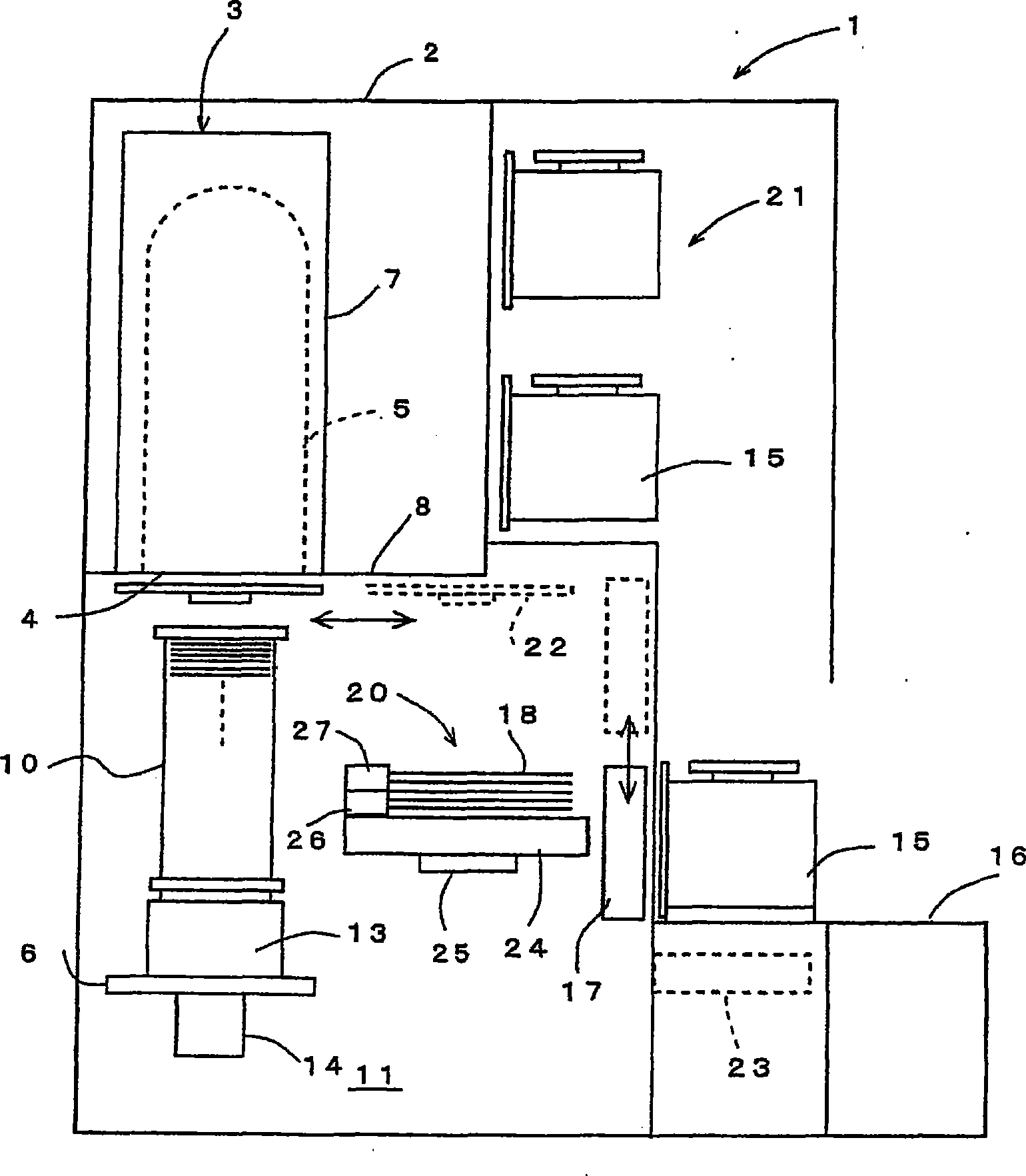

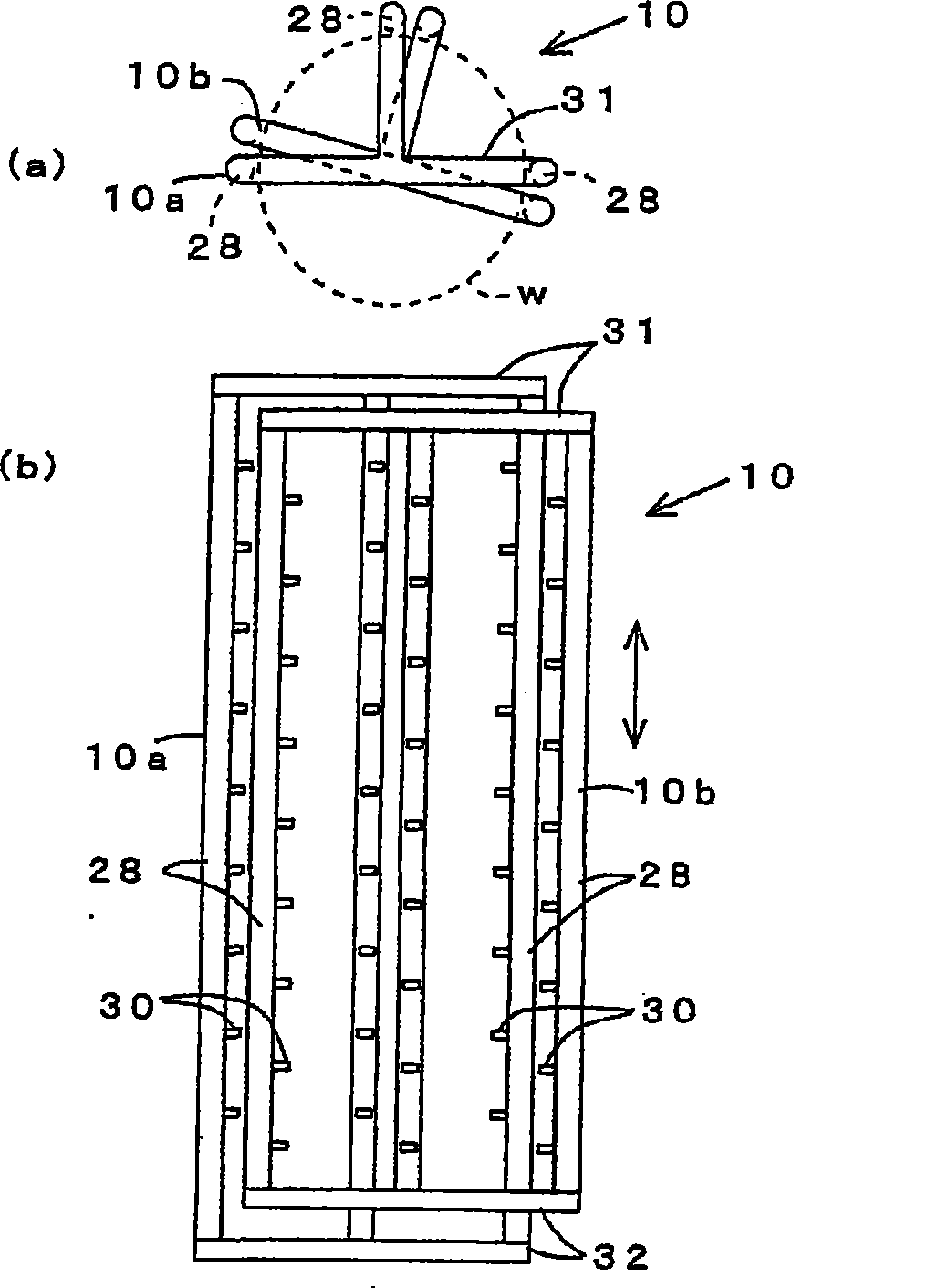

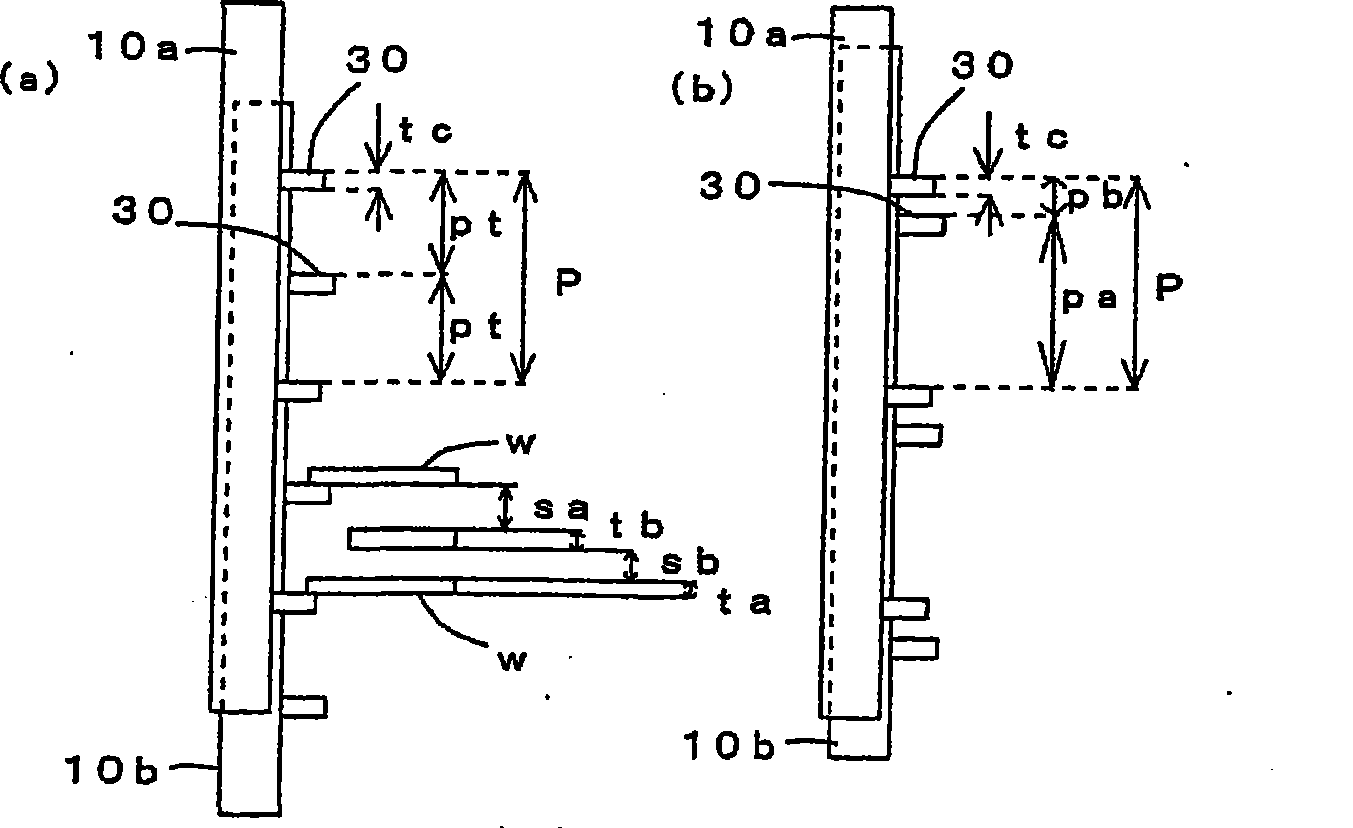

[0064] Below, the best mode for carrying out the present invention will be described in detail with reference to the drawings. figure 1 A longitudinal sectional view schematically showing a heat treatment apparatus according to an embodiment of the present invention, figure 2 It is a figure which schematically shows an example of a board|substrate holder, (a) is a top view, (b) is a front view.

[0065] exist figure 1 Among them, 1 is a vertical heat treatment device, and the heat treatment device 1 has a frame body 2 forming an outer shell. A vertical heat treatment furnace 3 is arranged above the frame body 2, wherein the heat treatment furnace 3 is used to accommodate a plurality of substrates to be processed, such as thin disc-shaped semiconductor wafers w, and to perform predetermined treatments, such as CVD treatment, on them. Wait. This heat treatment furnace 3 mainly comprises: the vertically long treatment container of lower part as furnace mouth 4 openings, such ...

no. 2 approach

[0094] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings. Figure 13 It is a longitudinal sectional view schematically showing a heat treatment apparatus according to an embodiment of the present invention, Figure 14 This is an explanatory diagram schematically illustrating an example in which two wafers are supported with their back faces facing each other using a support ring, Figure 15 It is a front view schematically showing the state in which two wafers are held on the wafer boat in the vertical direction and at a predetermined interval using the support ring, Figure 16 is a diagram representing a support ring, Figure 16 (a) is an overall schematic perspective view, Figure 16 (b) is an enlarged perspective view of main parts.

[0095] exist Figure 13 Among them, 101 is a vertical heat treatment device, and the heat treatment device 101 has a frame body 102 forming an outer shell. A verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com