Method and structure for thin film photovoltaic materials using semiconductor materials

A photovoltaic and semiconductor technology, applied in the direction of layered products, etc., can solve problems such as poor efficiency, poor reliability, long-term use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

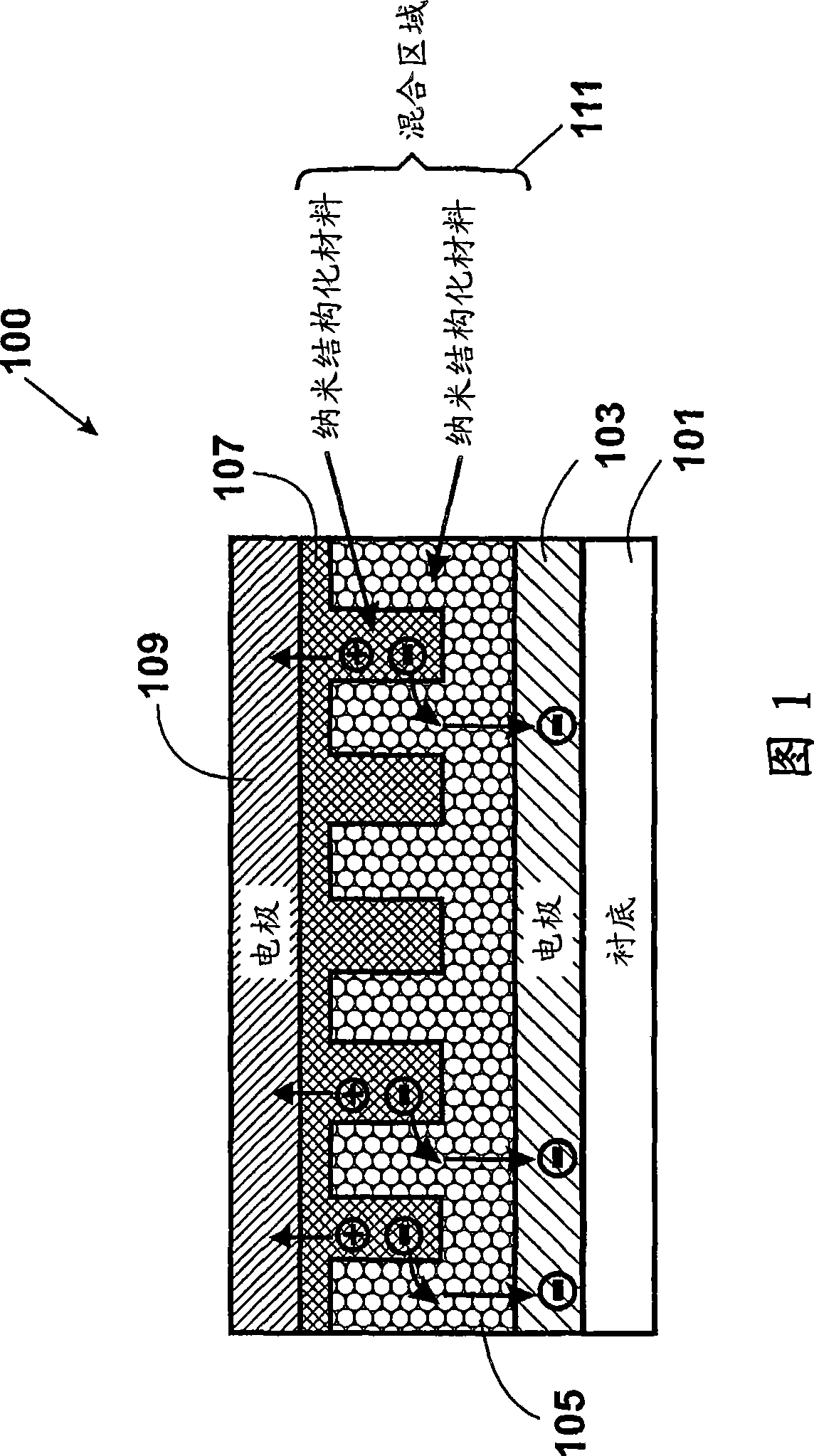

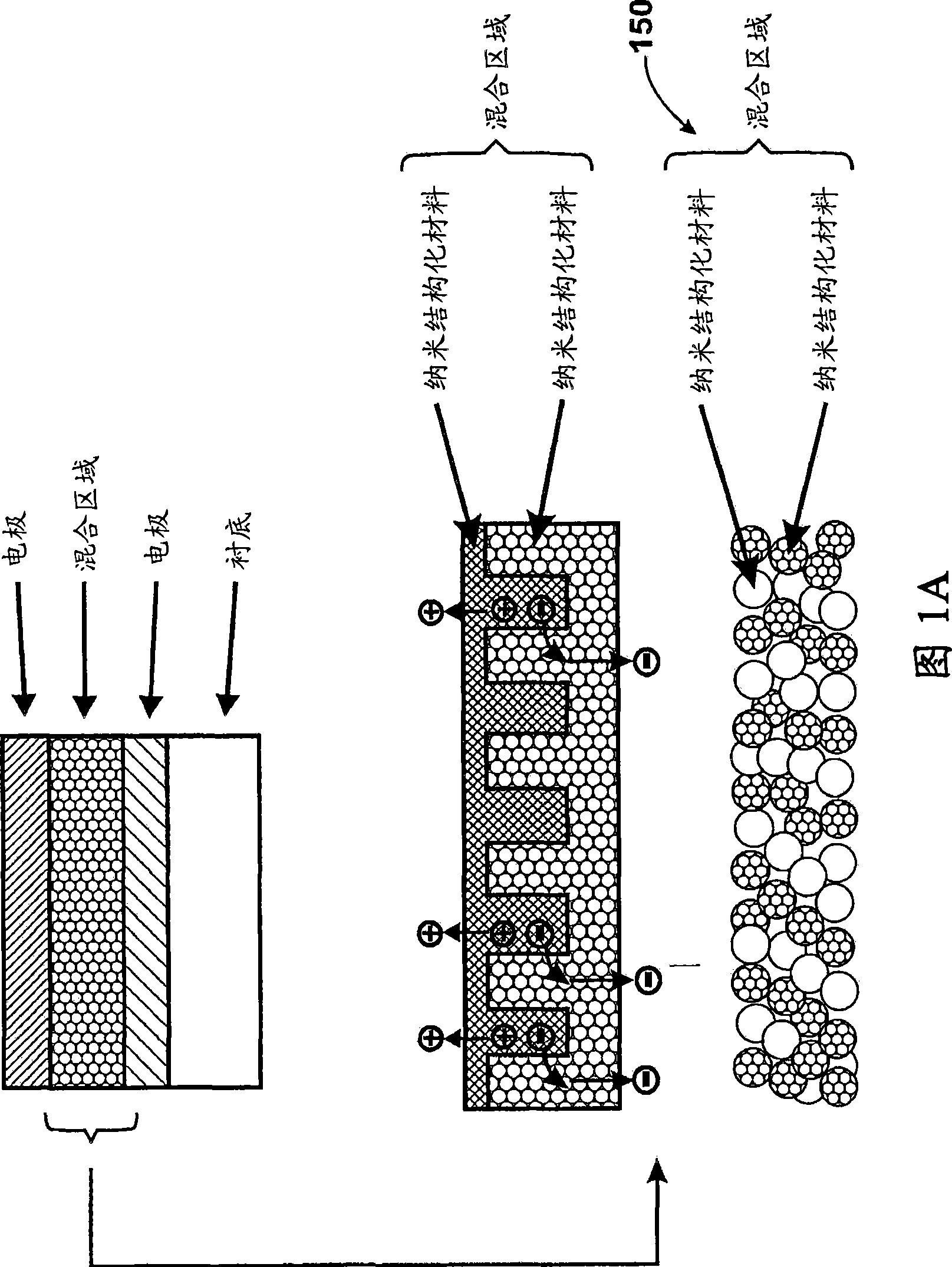

[0390] The substrate can be any optically transparent material such as glass, quartz glass, plastic, etc., on which the transparent conductive electrode (TCE) is deposited, which can employ various vacuum methods such as sputtering, evaporative deposition, and solution deposition. Examples of TCE are indium tin oxide (ITO), aluminum doped zinc oxide (ZnO:Al) and fluorine doped tin oxide (SnO 2 :F). In these examples we used ZnO:Al.

[0391] A nanoparticle (NP) layer of the first material is then deposited on the TCE. The thickness of the film can be from about 50 nm to about 1000 nm. This is performed using colloidal suspensions of NPs and various types of solution deposition methods such as spin coating, spray coating, inkjet printing, dip coating, doctor blade coating, electrophoresis, electrochemical deposition, etc. The deposited first material can be a metal oxide such as ZnO, TiO 2 , SnO 2 , WO 3 , Fe 2 o 3 Wait. In addition, the first material can make metal su...

Embodiment 2

[0395] In another embodiment of Example 1, NPs of the first material and NPs of the second material are deposited together in a similar pattern to the deposition of NPs of the first material in Example 1. As in Example 1, the two materials are then sintered for a specified time and temperature, or by applying pressure.

Embodiment 3

[0397] Start with TCE coated on the Example 1 substrate. Films of electron transporting hole blocking material (ETHBM) are deposited to a thickness of about 100 nm to about 1000 nm using vacuum techniques such as sputtering or evaporative deposition or solution deposition techniques. ETHBM can be metal oxides such as ZnO, TiO 2 , SnO 2 , WO 3 , Fe 2 o 3 etc., can be undoped or n-doped. The nanocomposite membranes described in Example 1 were then processed on the ETHBM. Finally, a top electrode is deposited on the nanocomposite film. The top electrode can be deposited by methods such as sputtering, evaporative deposition, screen printing, painting, thin film lamination, and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com