Foam spray fire extinguisher

A fire extinguisher and foam technology, applied in the field of special foam spray fire extinguishers, can solve the problems of main transformer safety threats, maintenance and management troubles, temperature-sensing cables being stepped on, etc., and achieve the effects of simple structure, convenient installation and maintenance, and easy observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

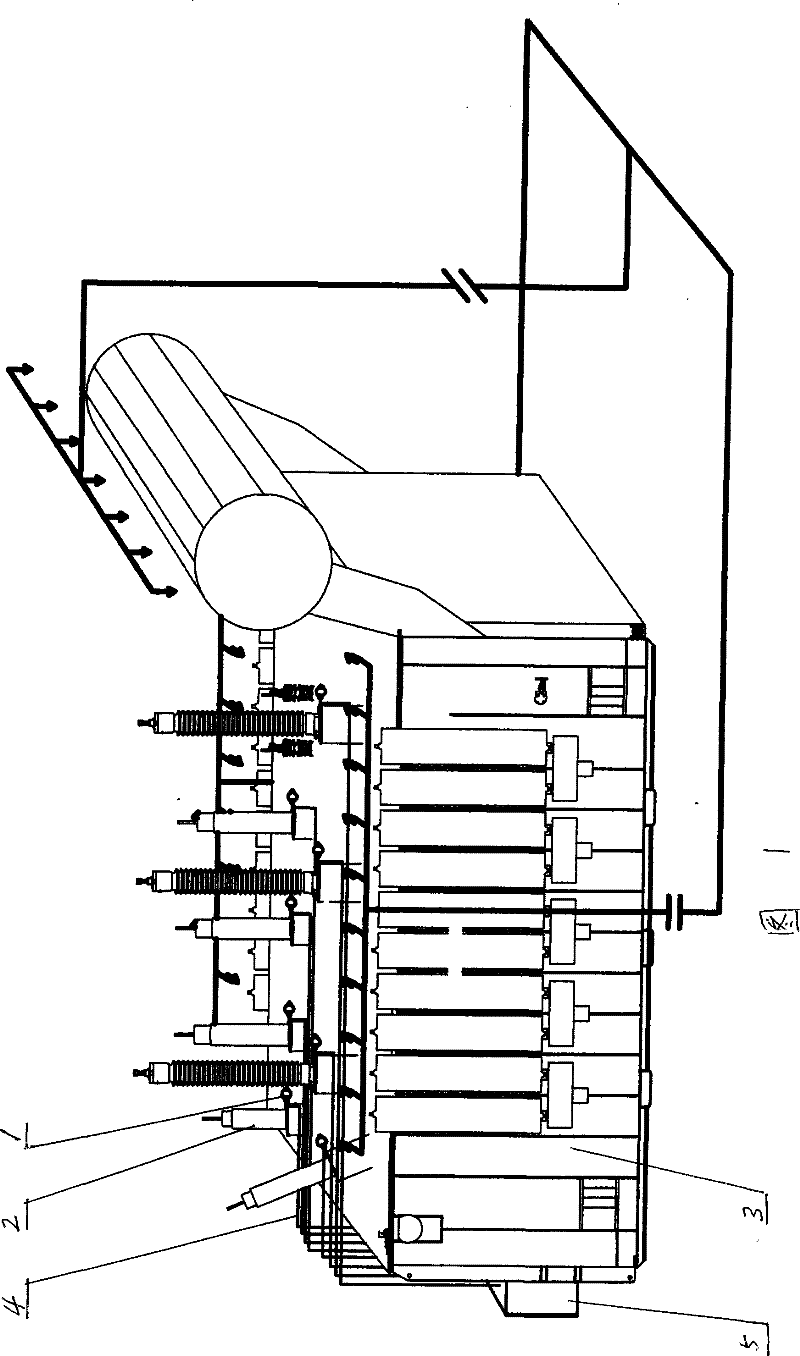

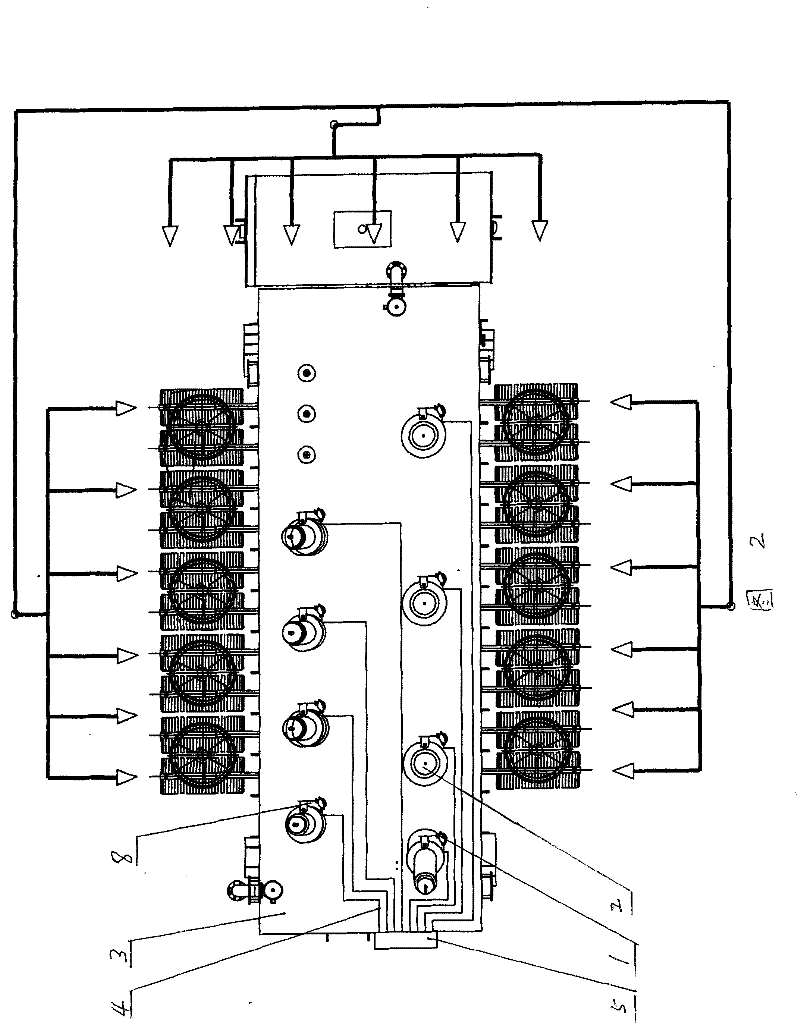

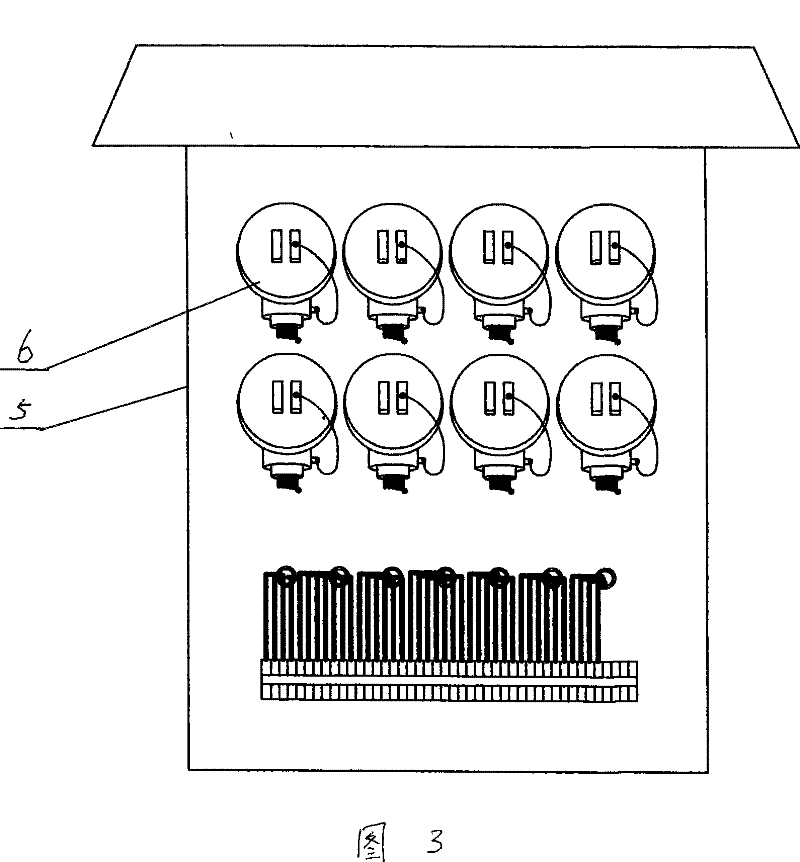

[0016] As shown in Figure 1, Figure 2, and Figure 3, the eight temperature probes 1 of this foam spray fire extinguisher are installed horizontally at the connection between the high-voltage bushing 2 and the main transformer 3, and each temperature probe 1 is connected by a temperature compensation line 4 and a temperature sensor. The temperature changer 6 in the change box 5 is connected. As shown in Figure 2 and Figure 4, the temperature probe 1 is installed in the spherical waterproof safety cover 7, and the stainless steel connecting piece 8 is welded outside the spherical waterproof installation cover 7, and is installed and fixed on the root of the high-voltage bushing 2 of the main transformer 3 by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com