Air-float pool for treating wastewater from melting

A technology for wastewater treatment and air flotation tank, which is applied in flotation water/sewage treatment and other directions, and can solve the problems of poor oil removal effect, short residence time and insufficient height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

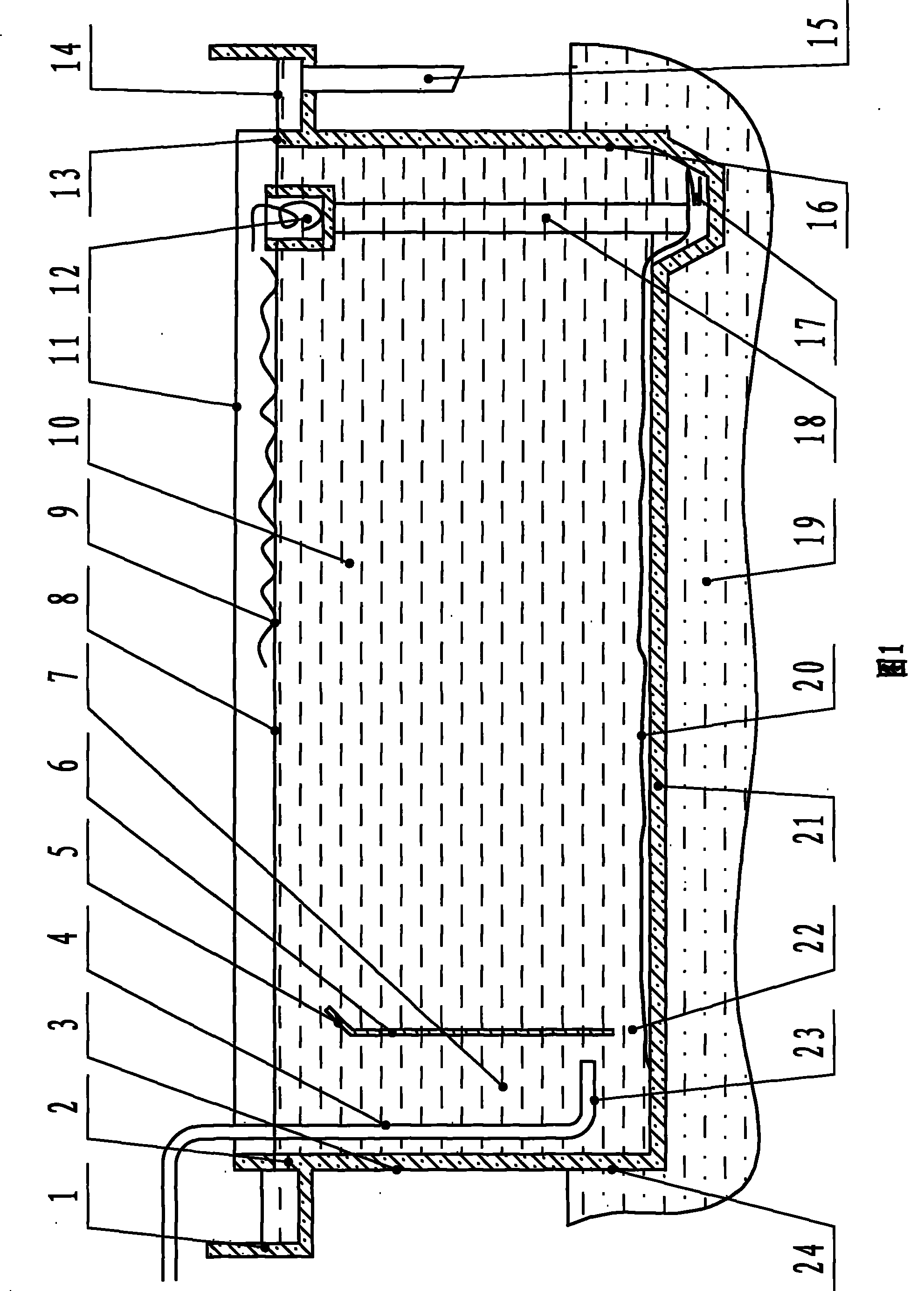

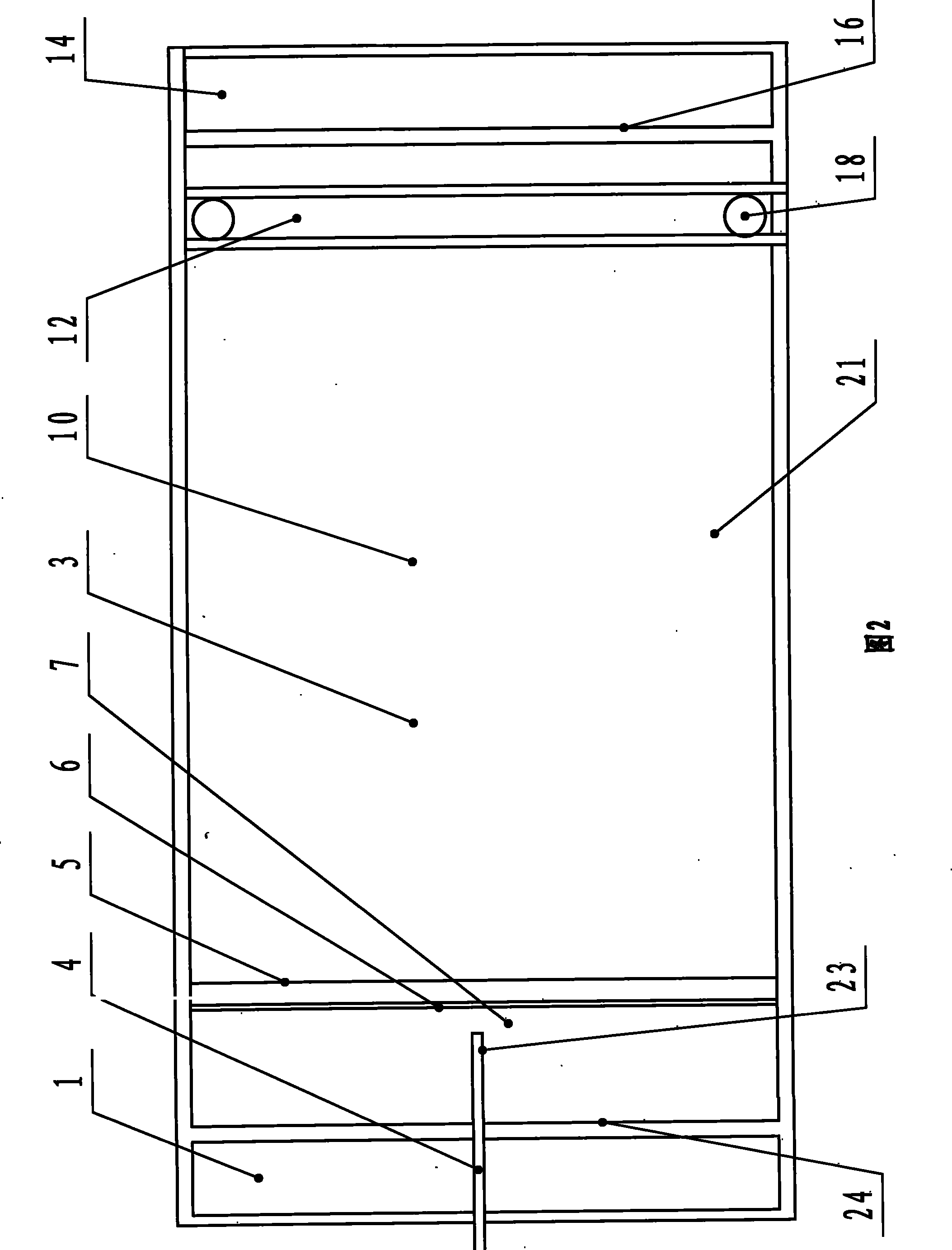

[0024] figure 1 and figure 2 The described air flotation tank for smelting wastewater treatment includes a pool body 3, a partition wall 6, an inlet channel 1, an outlet channel 14, a release device 23 and a slag discharge tank 12, and the partition wall 6 is horizontally arranged in the pool body 3 to separate the pool body 3 The inside is divided into a contact chamber 7 and a separation chamber 10. The water inlet channel 1 is arranged on the upper part of the front wall 24 of the water inlet side outside the pool body 3, and 50 water distribution holes 2 communicating with the water inlet channel 1 are distributed on the pool body 3. , the outlet channel 14 is arranged on the upper part of the rear wall 16 of the outlet side of the pool body 3 outside, and the outlet weir 13 communicating with the outlet channel 14 is arranged on the pool body 3, and the slag discharge groove 12 is arranged horizontally in the pool body 3 On the upper part of the water outlet side, a sl...

Embodiment 2

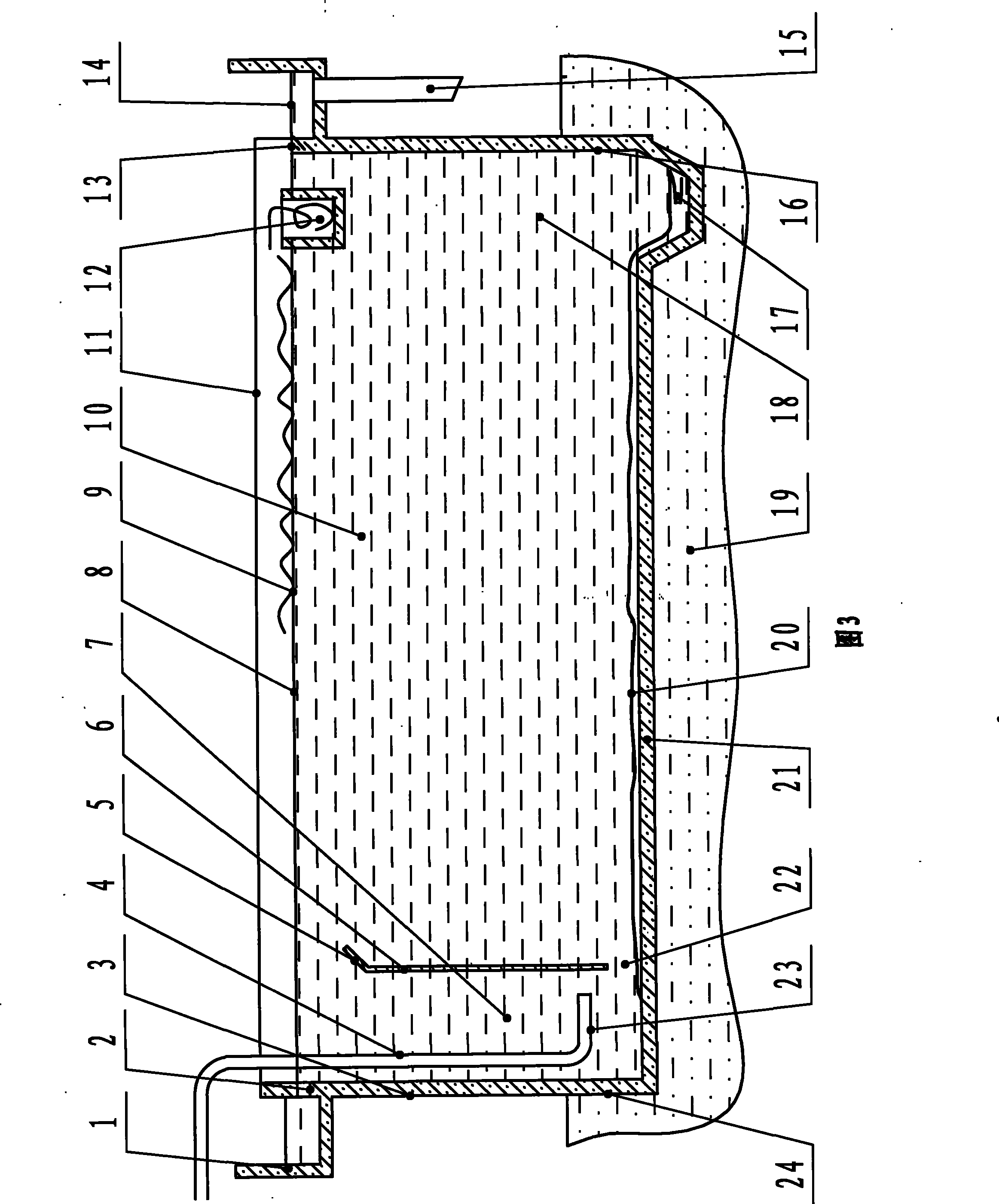

[0028] The structure of this embodiment see image 3 and Figure 4 , The difference between this embodiment and Embodiment 1 is that the two ends of the slag discharge tank 12 extend outside the pool body 3, and the slag discharge pipe 25 connected with the slag discharge pipe 12 is arranged outside the pool body 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com