Car engine cooling system heat radiator plate-type rubber seal strip assembly and manufacturing process thereof

A technology for automobile engines and rubber sealing strips, which is applied to household components, other chemical processes, other household appliances, etc., can solve the problems that restrict the development of the automobile industry, increase the cost of automobile production, rubber tear strength, elongation at break and tear Strength, compression deformation, high temperature aging resistance, and coolant aging resistance cannot meet the requirements, so as to achieve good sealing, improve tear strength, and good tear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

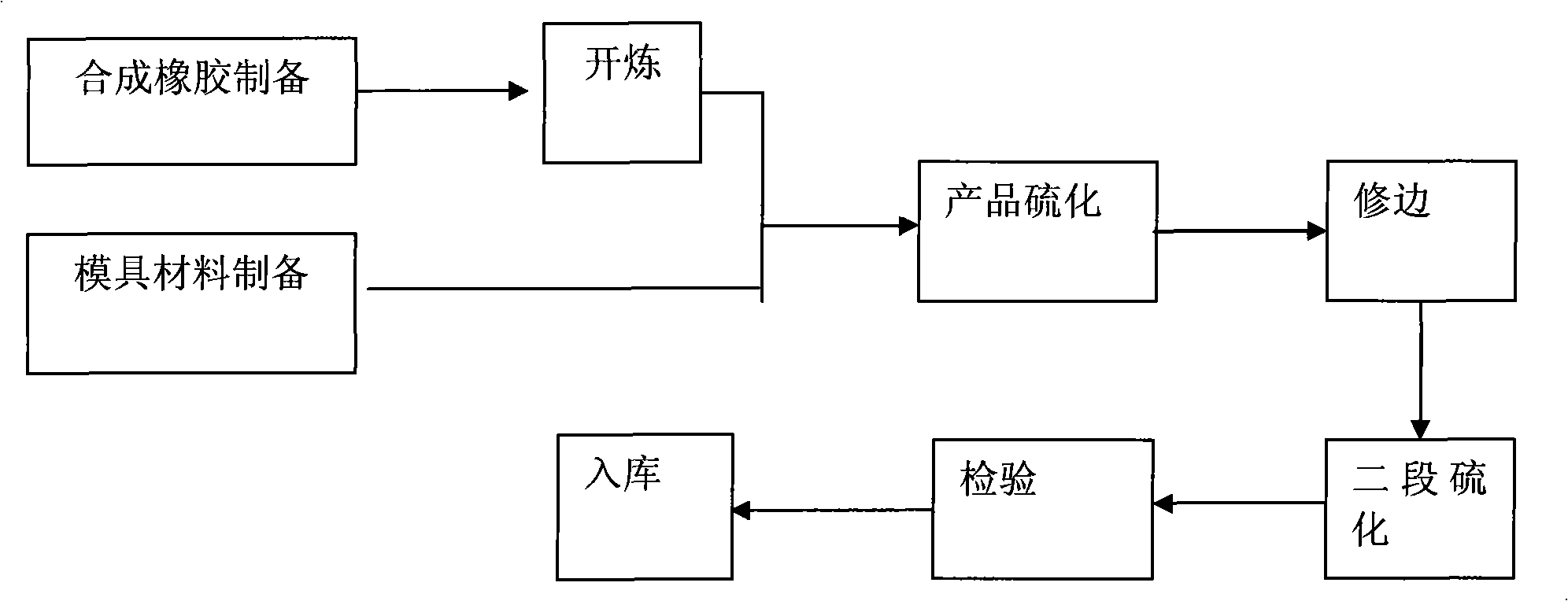

Image

Examples

Embodiment 1

[0025] The weight ratio of each raw material component of synthetic rubber is:

[0026] EPDM: 90 Carbon Black: 50

[0027] Paraffin oil: 20 Indirect zinc oxide: 4

[0028] Antiaging agent MBZ: 1.0 Lubricant WB42: 2

[0029] Vulcanizing agent double 2.5: 2.5 Accelerator Activator-70P: 1.0

Embodiment 2

[0031] The weight ratio of each raw material component of synthetic rubber is:

[0032] EPDM: 100 Carbon Black: 55

[0033] Paraffin oil: 25 Indirect zinc oxide: 5

[0034] Antiaging agent MBZ: 1.5 Lubricant WB42: 3

[0035] Vulcanizing agent double 2.5: 3.0 Accelerator Activator-70P: 1.5

Embodiment 3

[0037] The weight ratio of each raw material component of synthetic rubber is:

[0038] EPDM: 110 Carbon Black: 65

[0039] Paraffin oil: 30 Indirect zinc oxide: 6

[0040] Antiaging agent MBZ: 2.0 Lubricant WB42: 4

[0041] Vulcanizing agent double 2.5: 3.5 Accelerator Activator-70P: 2.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com