Titanium dioxide compound film optoelectronic pole and its production method

A technology of composite thin film and titanium dioxide is applied in the field of dye-sensitized solar cell materials to achieve the effects of reducing cost, improving photoelectric conversion performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

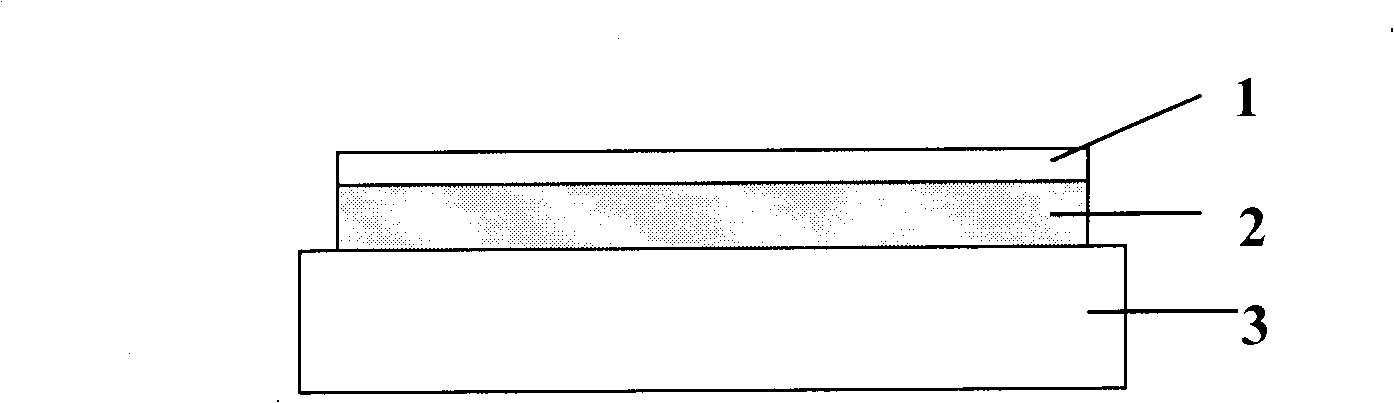

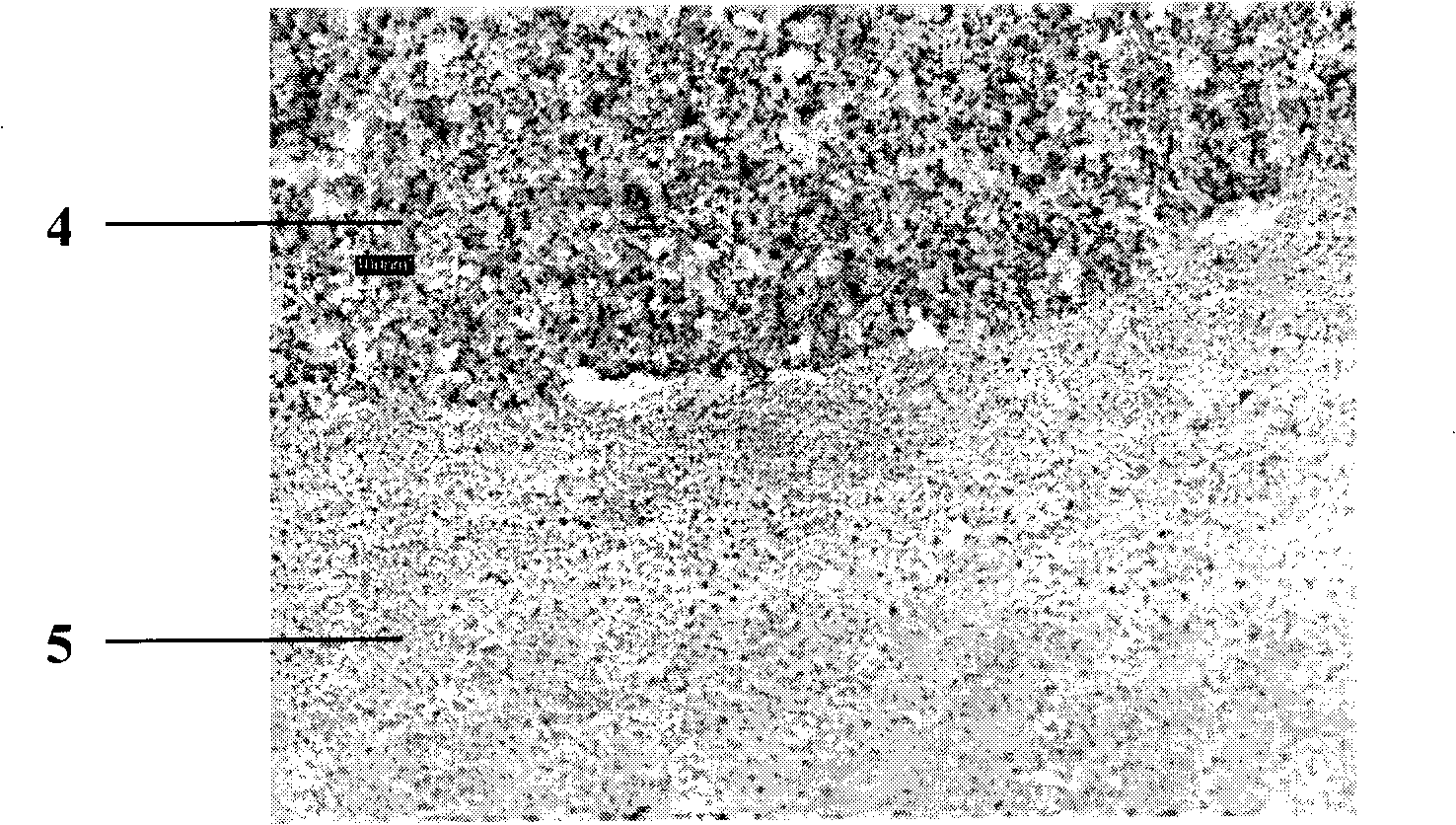

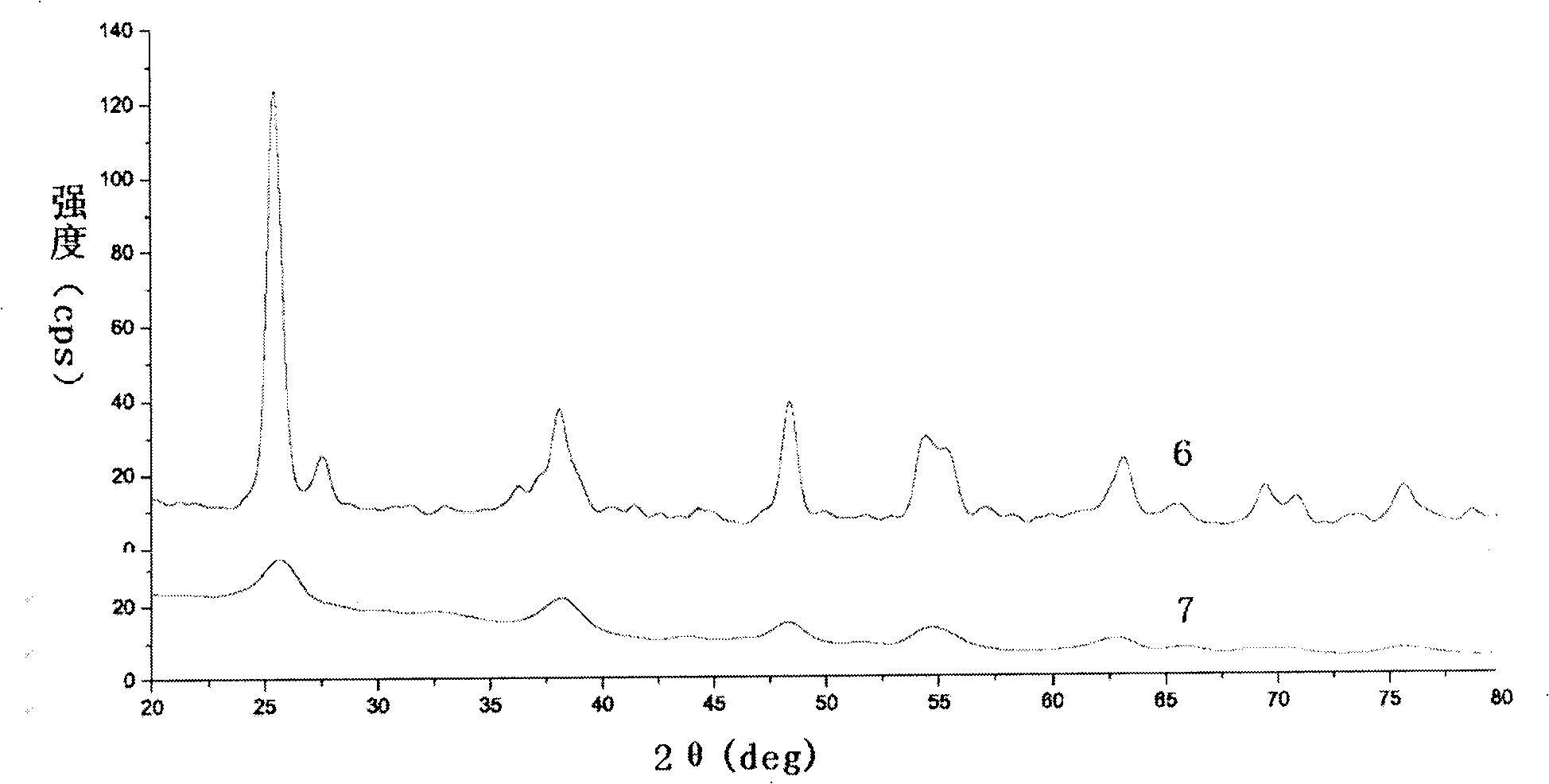

[0023] A titanium dioxide composite film photoelectrode is composed of a conductive substrate and a titanium dioxide composite film. Wherein, the conductive substrate is commercially available FTO conductive glass. The titanium dioxide composite film is composed of a layer of low-crystallinity TiO2 interconnected by spherical particles with a particle size of about 10-50 nm. 2 Mesoporous film and a layer of anatase TiO interconnected by nanocrystals with a particle size of 20-50nm 2 Composed of mesoporous films, the thickness of the composite film is 15 μm. Its low crystallinity TiO 2 Mesoporous Thin Film Layer and Anatase Nanocrystalline TiO 2 The thickness ratio of the mesoporous thin film layer is 1:0.5.

[0024] A preparation method of a titanium dioxide composite film photoelectrode, the specific steps are as follows:

[0025] (1) Preparation of low crystallinity TiO 2 Mesoporous film

[0026] Low crystallinity TiO composed of spherical particles with a particle si...

Embodiment 2

[0030] A titanium dioxide composite thin film photoelectrode, the same as embodiment 1, is characterized in that: the thickness of the composite thin film is 12 μm, low crystallinity TiO 2 Mesoporous thin film layer: anatase nanocrystalline TiO 2 The thickness ratio of the mesoporous thin film layer is 1:1.

[0031] The specific steps of a preparation method of a titanium dioxide composite thin film photoelectrode are as follows:

[0032] (1) Preparation of low crystallinity TiO 2 Mesoporous film

[0033] With embodiment 1. Features: Drying at 150°C for 10 minutes, calcining at 450°C for 30 minutes, low crystallinity TiO 2 The thickness of the mesoporous film is 6 μm.

[0034] (2) Preparation of titanium dioxide composite thin film photoelectrode

[0035] With embodiment 1. The characteristics are: drying at 100°C for 5 minutes, calcining at 450°C for 30 minutes, anatase nanocrystalline TiO 2 The thickness of the mesoporous film is 6 μm, and the low crystallinity TiO ...

Embodiment 3

[0037] A titanium dioxide composite film photoelectrode, the same as embodiment 1, is characterized in that: the thickness of the composite film is 14 μm, low crystallinity TiO 2 Mesoporous thin film layer: anatase nanocrystalline TiO 2 The thickness ratio of the mesoporous thin film layer is 1:0.4.

[0038] The specific steps of a preparation method of a titanium dioxide composite thin film photoelectrode are as follows:

[0039] (1) Preparation of low crystallinity TiO 2 Mesoporous film

[0040] With embodiment 1. Features: Drying at 150°C for 10 minutes, calcining at 450°C for 30 minutes, low crystallinity TiO 2 The thickness of the mesoporous film is 10 μm.

[0041] (2) Preparation of titanium dioxide composite thin film photoelectrode

[0042] With embodiment 1. The characteristics are: drying at 100°C for 5 minutes, calcining at 450°C for 30 minutes, anatase nanocrystalline TiO 2 The thickness of the mesoporous film is 4 μm, low crystallinity TiO 2 Mesoporous Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com