Improved solar cell front electrode and its production method

A technology of a solar cell and a manufacturing method, which is applied in the field of solar energy, can solve the problems of reduced short-circuit current, large contact area, and reduced photoelectric conversion efficiency of solar cells, and achieves improved photoelectric conversion efficiency, good short-wave spectral response, and less hole recombination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

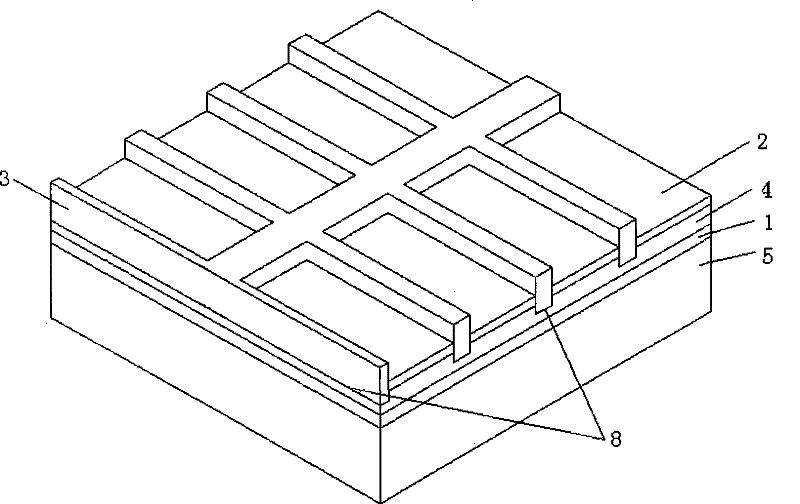

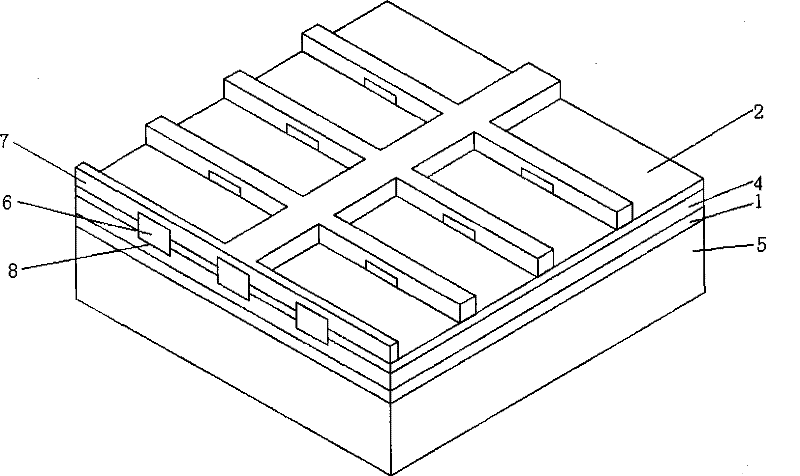

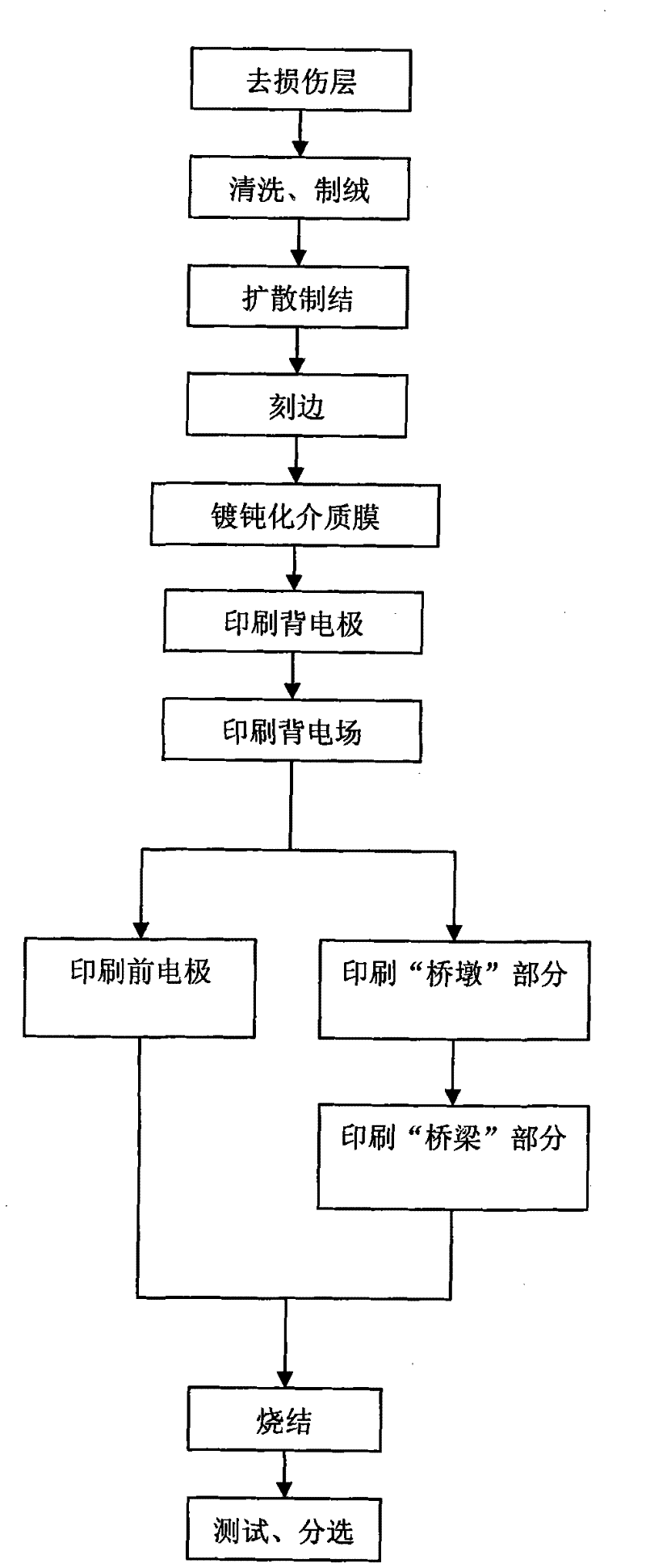

[0020] Such as figure 2 As shown, the beam bridge electrode of the present invention is composed of two parts of electrodes: one part is the pier part 6, which penetrates the passivation dielectric film 2, and the bottom forms a point contact with the emission area 4 of the solar cell; the other part is the bridge part 7, This part of the electrode is covered on the pier part 6 and the passivation medium film 2 of the solar cell, and the bottom is not in direct contact with the emission area 4 of the solar cell, and it only plays the role of connecting the pier part 6 and conducting current. In the embodiment of the present invention, the bridge pier parts 6 of the beam bridge electrodes are equidistantly distributed on the front surface of the solar cell, and the bridge part 7 of the beam bridge electrode is connected to each bridge pier part 6 distributed on the front surface of the solar cell. The beam bridge electrode is only in contact with the emitter region 4 of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com