Silicon solar cell of transparent conductive film front electrode

A transparent conductive film and solar cell technology, applied in semiconductor devices, circuits, photovoltaic power generation, etc., can solve problems such as inability to convert electricity, capture photogenerated carriers, and loss of solar cell conversion efficiency, so as to increase output power and improve Effect of short-wave spectral response and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

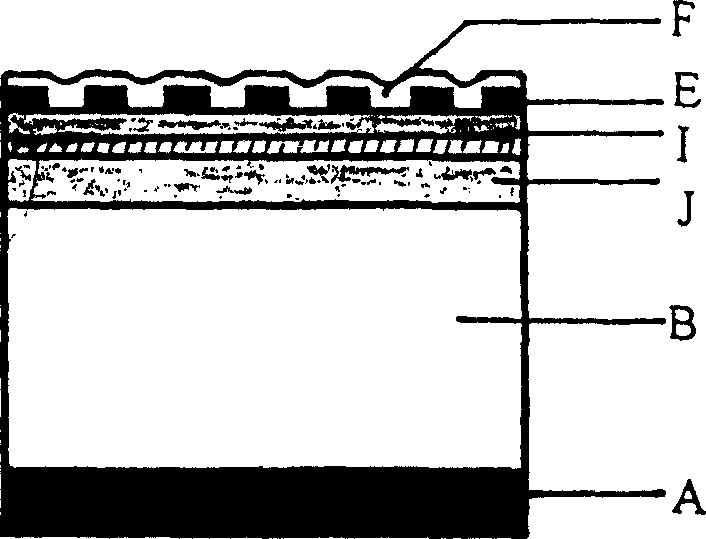

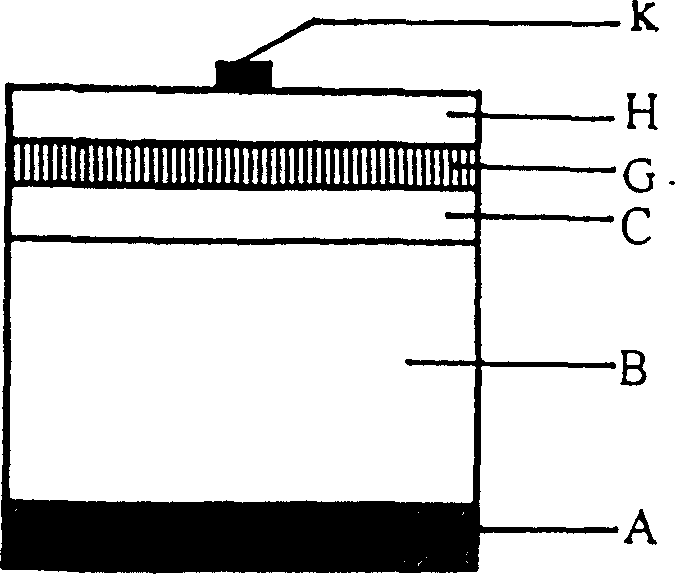

[0032] High-resistance transparent conductive film barrier layer using amorphous SnO 2 , Prepared by PECVD, high resistivity can be obtained. Generally resistivity ≥ 10 4 Ω.cm. The conductive layer of the high-conductivity transparent conductive film adopts doped SnO 2 . The specific implementation is as follows: first, a barrier layer (G) with a thickness of 5-10 nm is prepared by PECVD technology. Then prepare the conductive layer (H) of the high-conductivity transparent conductive film by the sputtering method, the low-pressure CVD method or the normal-pressure CVD method. The thickness is controlled to be 150-750 nm or thicker according to the anti-reflection conditions. Finally, the metal front electrode (K) is fabricated by screen printing, sputtering or vacuum evaporation. Generally, the density of front electrode strips is 0.5-2 strips / cm.

[0033] When amorphous SnO 2 The resistivity of the barrier layer is 10 4 Ω.cm, thickness 5nm; doped SnO 2 The conductivi...

Embodiment 2

[0035] High-resistance transparent conductive film barrier layer using amorphous SnO 2 , the conductive layer of high-conductivity transparent conductive film adopts ITO thin film, and can also use doped ZnO thin film or Cd 2 SnO 4 film. A barrier layer (G) of 5-10 nm is firstly prepared by PECVD technology. Then, the conductive layer (H) of the high-conductivity transparent conductive film is prepared by the sputtering method or the APCVD method, and the thickness is 150-750nm or thicker. Finally, the metal front electrode (K) was prepared as described in Example 1.

[0036] When amorphous SnO 2 The resistivity of the barrier layer is 10 4 Ω.cm, the thickness is 5nm; the conductivity of the conductive layer of the ITO transparent conductive film is 1.5×10 4 (Ω.cm) -1 , when the thickness is 600nm, the conversion efficiency is about 35% higher than that of the grid-shaped front electrode.

Embodiment 3

[0038] High resistance transparent conductive film barrier layer SnO 2 Polycrystalline film is used, and the conductive layer of high-conductivity transparent conductive film adopts doped SnO 2 thin film or ITO film, or doped ZnO thin film, Cd 2 SnO 4 film. Firstly, an undoped high-resistance transparent conductive film barrier layer (G) is prepared by low-pressure CVD or normal-pressure CVD. Since its resistivity is between 5-10Ω.cm, its thickness is controlled at about 100nm. Then, according to the technique described in Example 1 or Example 2, a conductive layer (H) of a high-conductivity transparent conductive film is produced, with a thickness of 150-750 nm, or thicker. That is, SnO can be prepared by sputtering method, low pressure CVD method or normal pressure CVD method 2 Polycrystalline thin film transparent conductive film conductive layer; or use sputtering method, normal pressure CVD method to prepare ITO film; or use other methods to prepare doped ZnO thin fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com