A kind of preparation method of high-efficiency solar cell

A solar cell, high-efficiency technology, applied in the field of solar cells, can solve the problem of high cost, achieve the effect of reducing cost consumption, saving cost consumption, and reducing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

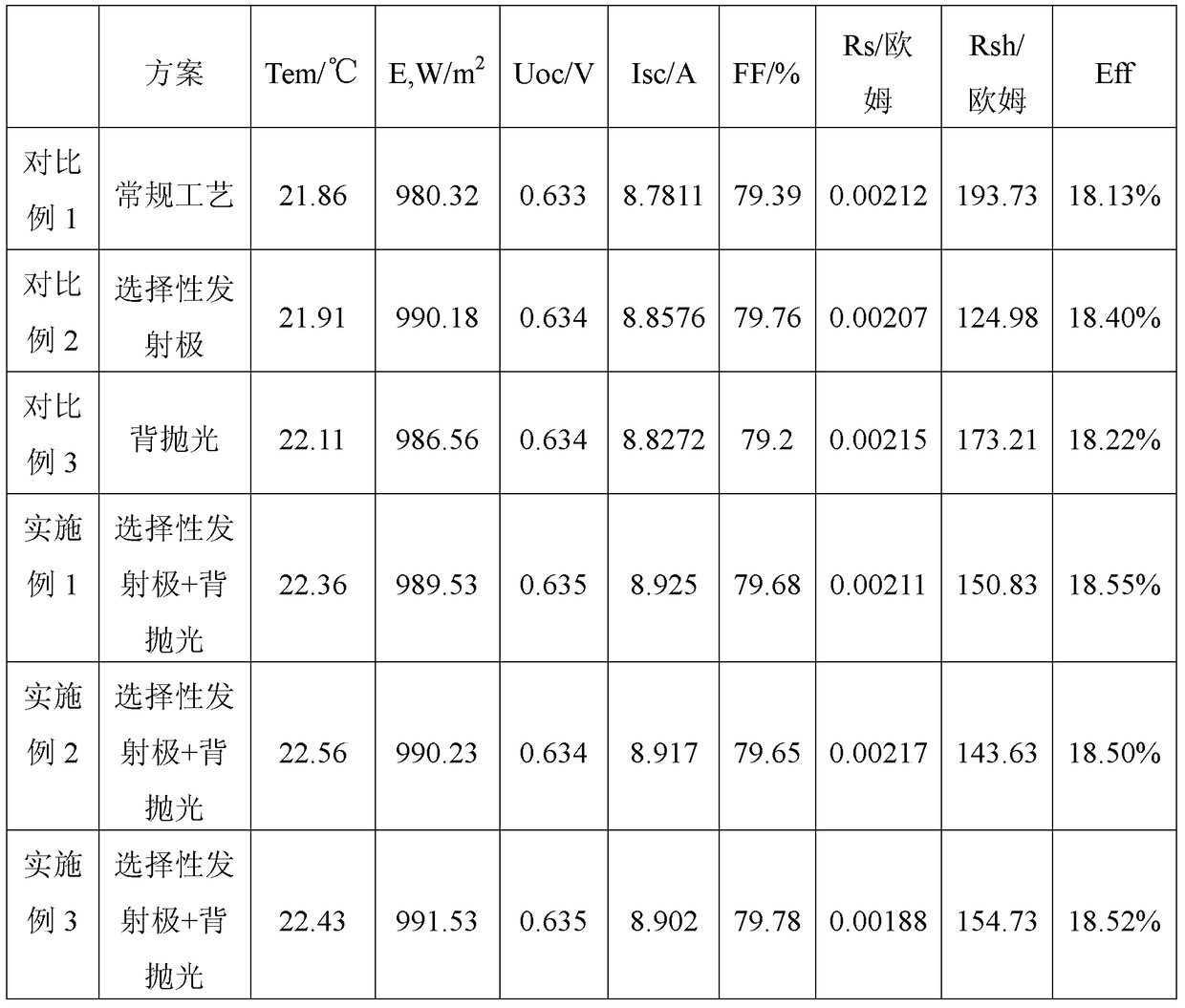

Embodiment 1

[0033] After cleaning and texturing the raw silicon wafers, one-sided low-resistance diffusion is carried out in a phosphorus oxychloride atmosphere, and the resistance after diffusion is controlled at 50Ω / ◇; the diffusion side of the silicon wafers is placed in an alkali tank chain back polishing machine. The feeding end of the material passes through an alkali tank containing a KOH aqueous solution with a concentration of 60 °C and a mass percentage of 20% at a rate of 1.5 m / min, and the backside is polished in the KOH aqueous solution for 8.0min. The residual alkali is washed in the pure water tank of water, and the upper and lower surfaces of the silicon wafer are dried in the drying section, and the silicon wafer is smoothly taken out from the blanking end.

[0034] To make a selective emitter:

[0035] a. Put the back-polished silicon wafer into the INK printer to print ink on the electrode grid line area of the silicon wafer as a mask, and dry it.

[0036] b. Put the...

Embodiment 2

[0043] After the raw silicon wafer is cleaned and textured, one-sided low-resistance diffusion is carried out in a phosphorus oxychloride atmosphere, and the resistance after diffusion is controlled at 55Ω / ◇; the diffusion side of the silicon wafer is placed in an alkali tank chain back polishing machine. The feeding end of the silicon wafer passes through an alkali tank containing a KOH aqueous solution with a concentration of 80 ℃ and a mass percentage of 10% at a rate of 2.2m / min, and the backside is polished in the KOH aqueous solution for 5.5min. After the backside polishing is completed, the silicon wafer is filled with pure water. The residual alkali is washed in the pure water tank, and the upper and lower surfaces of the silicon wafer are dried in the drying section, and the silicon wafer is smoothly taken out from the blanking end.

[0044] To make a selective emitter:

[0045] a. Put the back-polished silicon wafer into the INK printer to print ink on the electrode ...

Embodiment 3

[0053] After cleaning and texturing the raw silicon wafers, one-sided low-resistance diffusion is carried out in a phosphorus oxychloride atmosphere, and the resistance after diffusion is controlled at 52Ω / ◇; the diffusion side of the silicon wafers is placed in an alkali tank chain back polishing machine. The feeding end of the silicon wafer passes through an alkali tank containing a NaOH aqueous solution with a concentration of 70°C and a mass percentage of 35% at a rate of 1.8m / min, and the backside is polished in the NaOH aqueous solution for 6.67min. After the backside polishing is completed, the silicon wafer is filled with pure water. The residual alkali is washed in the pure water tank, and the upper and lower surfaces of the silicon wafer are dried in the drying section, and the silicon wafer is smoothly taken out from the blanking end.

[0054] To make a selective emitter:

[0055] a. Put the back-polished silicon wafer into the INK printer to print ink on the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com