Wet-method etching device for oxide film

An oxide thin film, wet etching technology, used in sustainable manufacturing/processing, electrical components, climate sustainability, etc. Uniformity and other problems, to achieve the effect of small concentration fluctuation range, cancellation of waiting time, and shortening of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached with the manual Figure 1-6 A preferred embodiment of the present invention will be introduced.

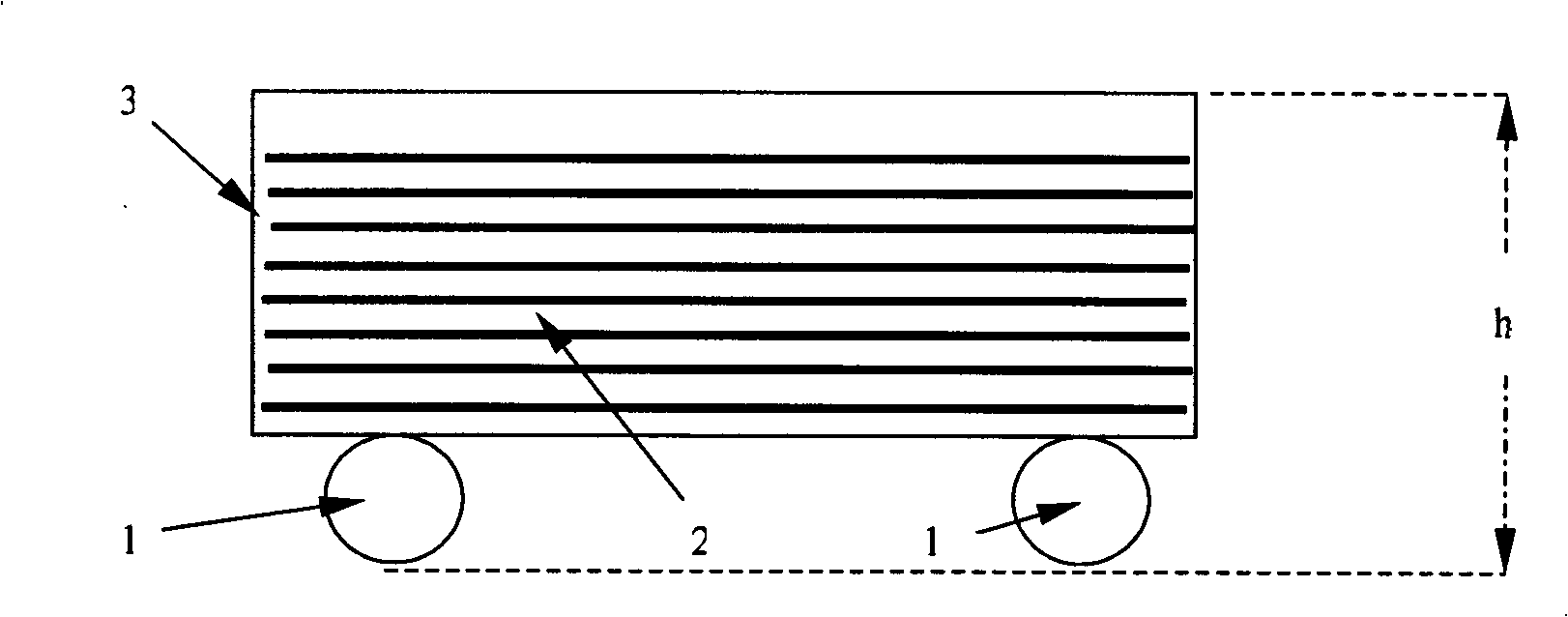

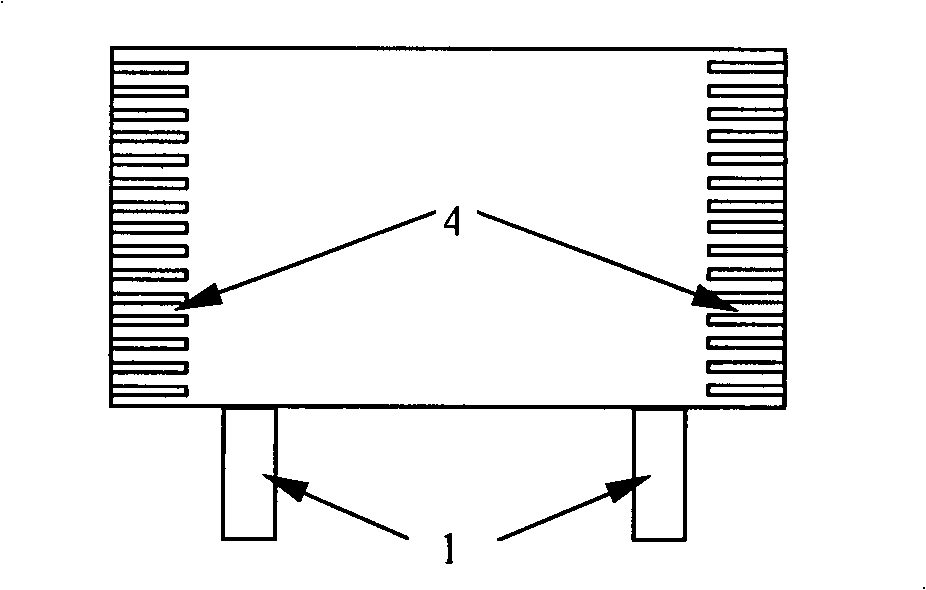

[0034] Such as figure 1 and 2 As shown, the present invention uses a dolly with 4 wheels 1 as the carrier 9 for loading the substrate 2, the height of the dolly is h, and 2 wheels are respectively equipped on both sides of the bottom of the dolly, and 50 film substrates 2 are stacked on the upper part. And it is fixed by the substrate clamp 4, so that the substrate 2 will not fall during the movement of the dolly. The control unit is connected to the rear side 3 of the trolley through a transmission device to control the movement of the trolley.

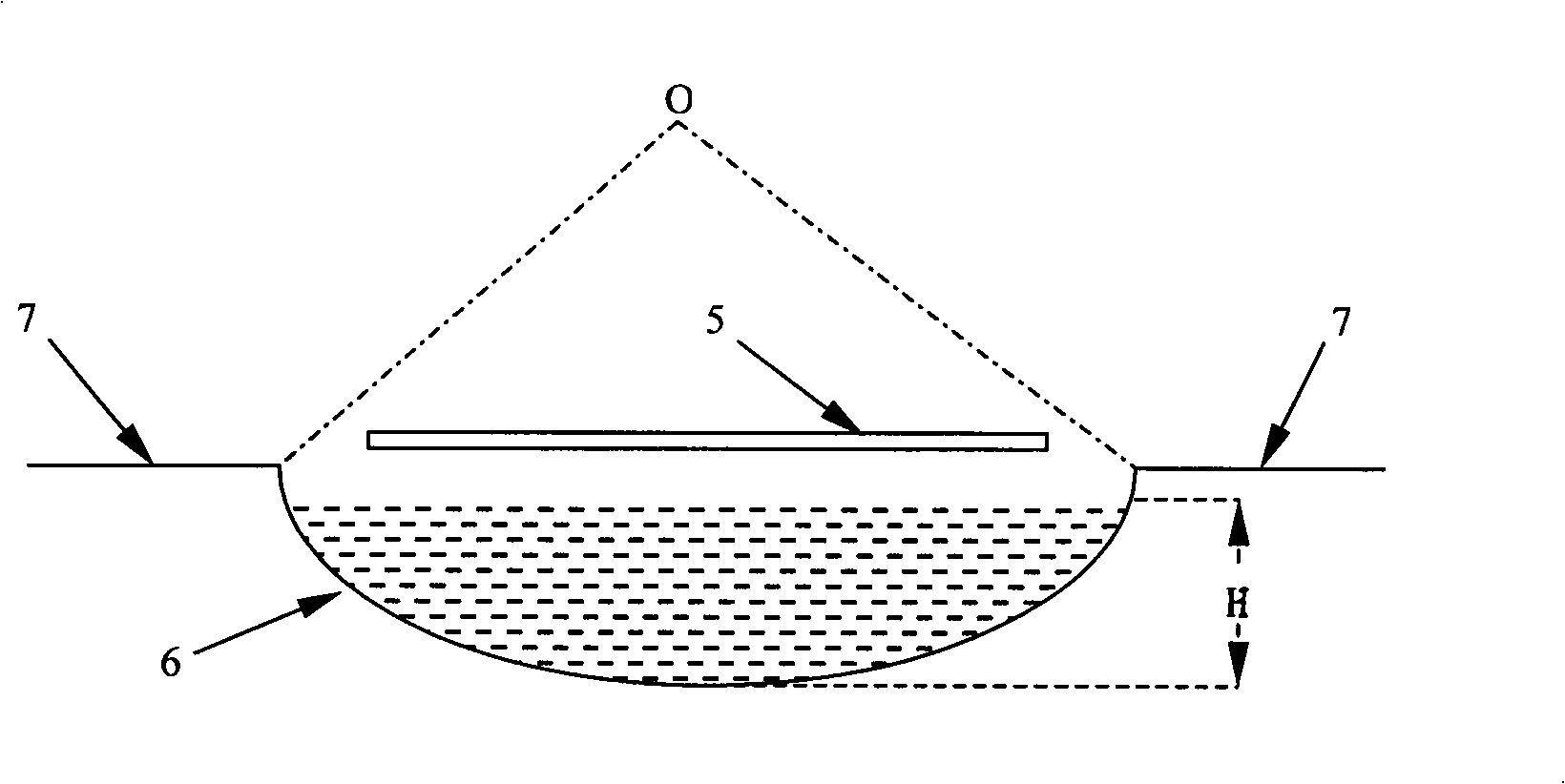

[0035] Such as image 3 As shown, the arc bottom etching groove 8 with point O as the center of the circle has a depth of H, and H is greater than h, and the acid solution can completely immerse the trolley. Two arc-shaped rails 6 are arranged along the arc at the bottom of the etching groove 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com