Miniature direct-drive permanent magnet synchronous aerogenerator and its small-sized wind power generation system

A wind power generation system, wind power generator technology, applied in the direction of multi-output synchronous motors, synchronous motors with stationary armatures and rotating magnets, wind power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

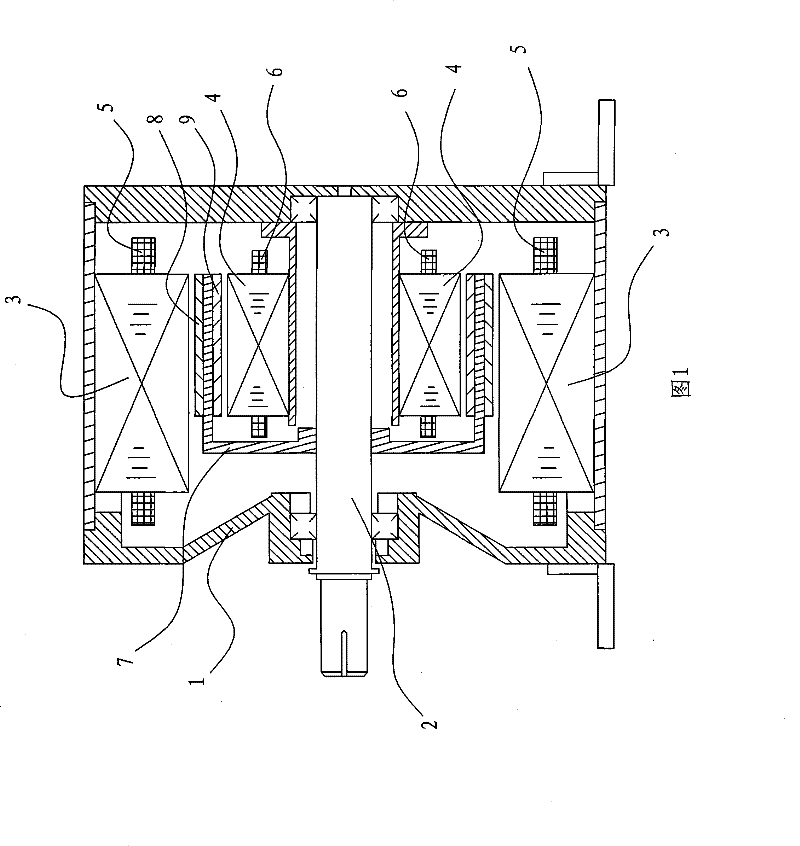

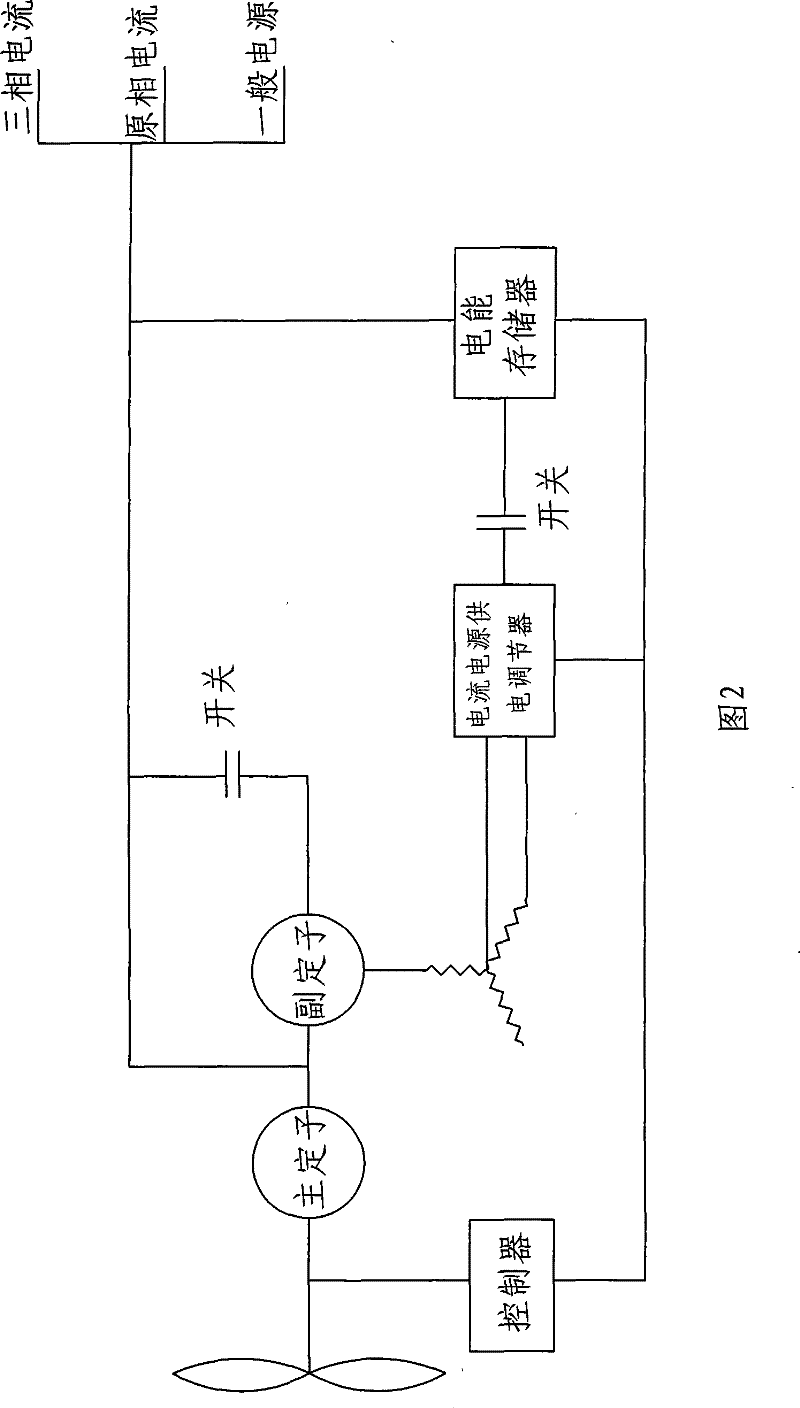

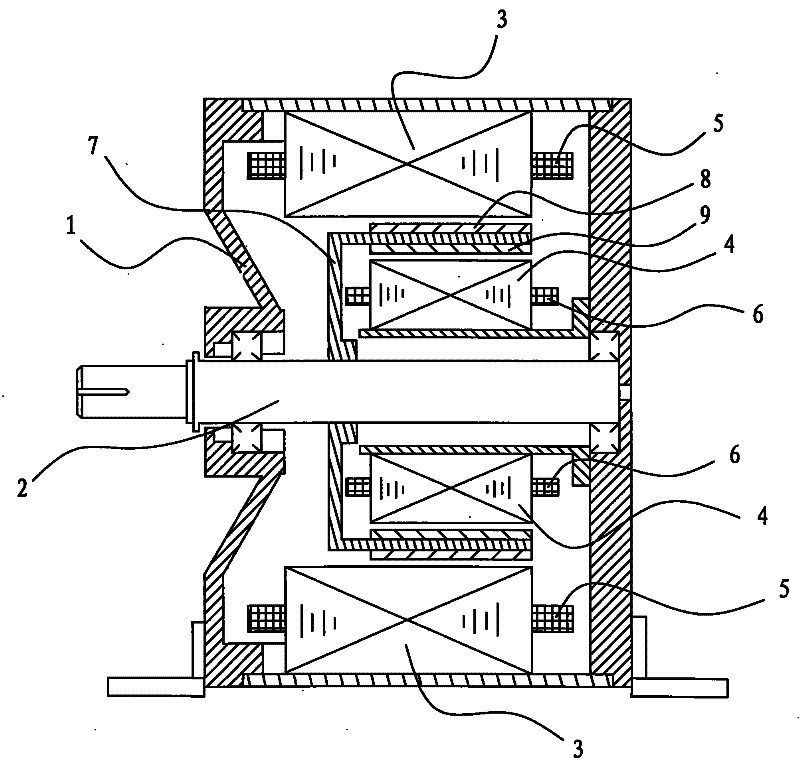

[0020] refer to figure 1 , a small direct-drive permanent magnet synchronous wind power generator of the present invention, including a casing 1, the casing 1 is installed with a rotating shaft 2 through bearings, a main stator 3 and an auxiliary stator 4 are installed and fixed in the casing 1, and there are 3 sets of main stators On the periphery of the auxiliary stator 4, the main stator 3 and the auxiliary stator 4 have a main stator winding 5 and an auxiliary stator winding 6 respectively, and a rotor 7 connected to the rotating shaft 2 is arranged between the main stator 3 and the auxiliary stator 4, and the rotor 7 There are outer permanent magnets 8 and inner permanent magnets 9 corresponding to the main stator 3 and the auxiliary stator 4 respectively, and one phase winding of the auxiliary stator winding 6 is connected to a DC power supply adjustment control terminal.

[0021] Further, as a preferred embodiment of the present invention, the motor stator and rotor ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com