Process for production of a profile strip

A technology of profiles and plastic profiles, applied in furniture accessories, crafts for producing decorative surface effects, decorative arts, etc., can solve the problems of expensive and complex profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

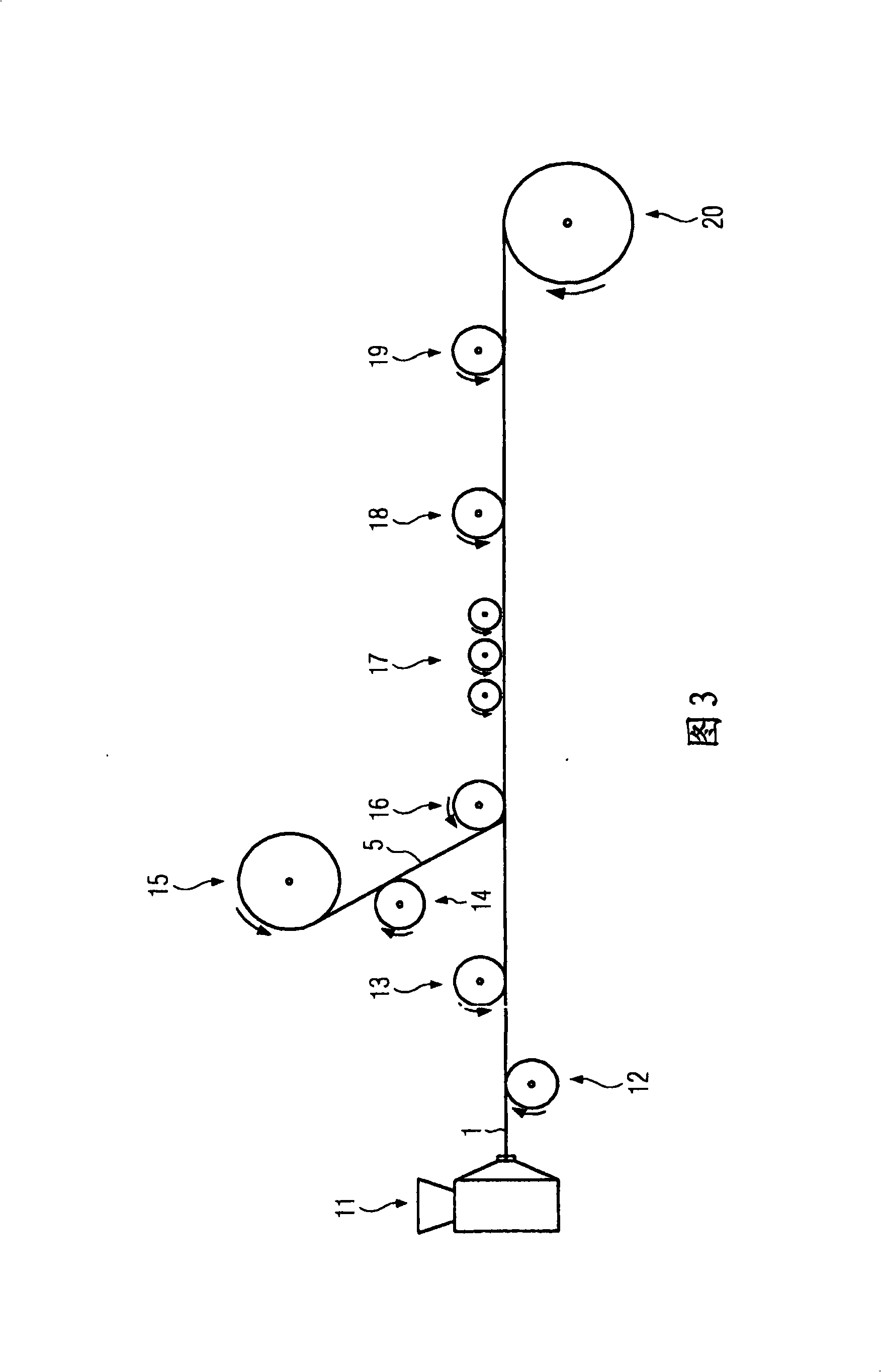

Method used

Image

Examples

Embodiment Construction

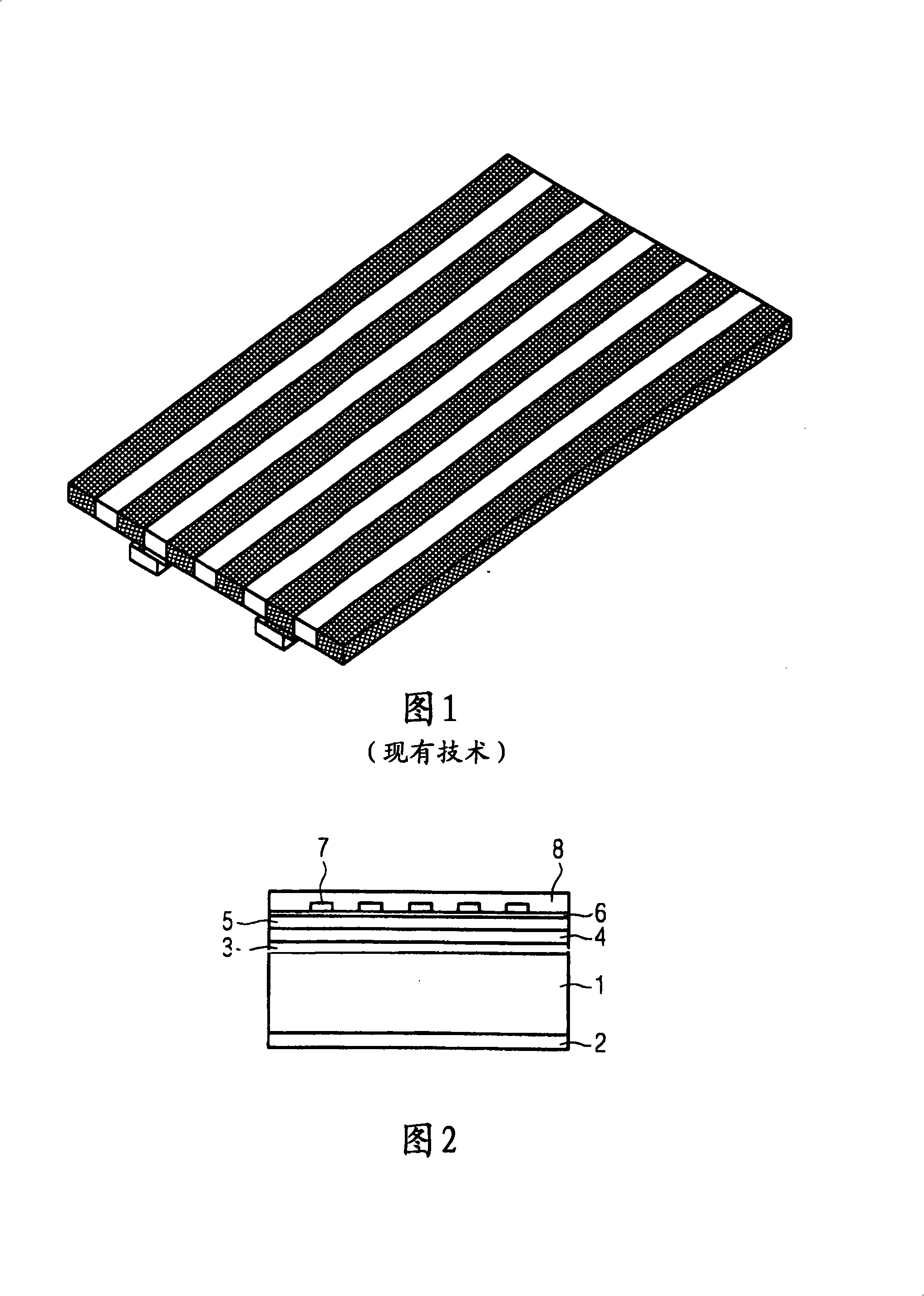

[0028] In the following description, positional terms such as "upper", "lower", "top", "bottom" etc. are used which refer to the intended assembled state of the profile strip. During intended use, the profile strip is used to fasten it to a foundation with the bottom side referenced 2 so that the top side referenced 8 forms the outer surface of the profile strip.

[0029] The profile strip according to the invention or produced according to the invention will be described in detail with reference to FIG. 2 . The cross-section in FIG. 2 is only used to visualize the layer structure of the profile strip. The view of Figure 2 is not to scale and not limiting. In practice the profile strips produced according to the invention have a thickness of in particular approximately 0 to 4 mm (millimeters), preferably 1.5 mm. The width of the profile strip produced according to the invention can vary depending on the purpose of use and is in particular between 10 and 70 mm.

[0030] A pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com