Method for temperature manipulation of a melt

A melt and purification method technology, applied in the field of clarification and/or purification of melt, clarification and/or purification device, and glass products, can solve problems such as difficulty in starting, heat loss of electrodes, etc., and reduce the risk of flashover , reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

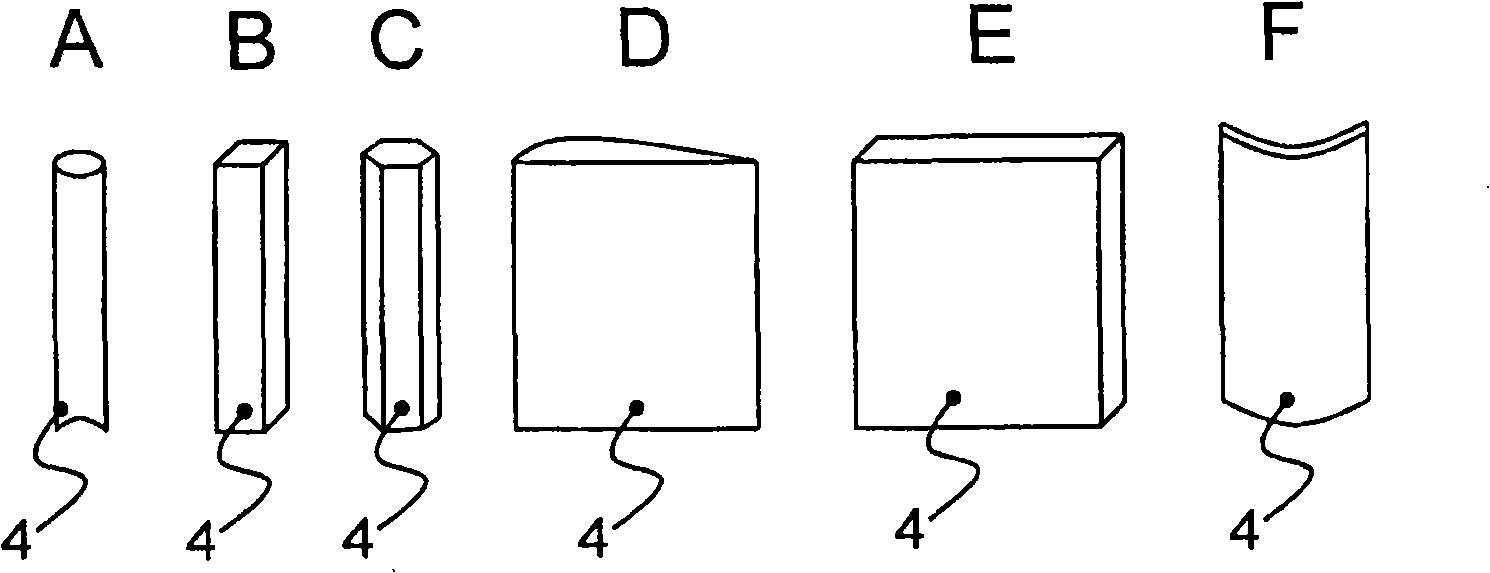

[0162] For the configuration of the interior of the container according to the device according to the invention, rod-shaped electrodes or plate-shaped electrodes can be used in particular. exist figure 1 , a schematic selection of these electrodes 4 is shown. Rod electrodes can have a round shape ( figure 1 A), rectangle ( figure 1 B) or a polygon ( figure 1 C) Cross section. The geometry of the plate electrodes can also be varied. For example, when flow influence is required, a shape suitable for flow can be selected ( figure 1 D). Likewise, it is possible to use simple plate electrodes with bulk geometry ( figure 1 E). To influence the flow, very different shapes can be chosen, e.g. electrodes can also have curved cross-sections ( figure 1 F).

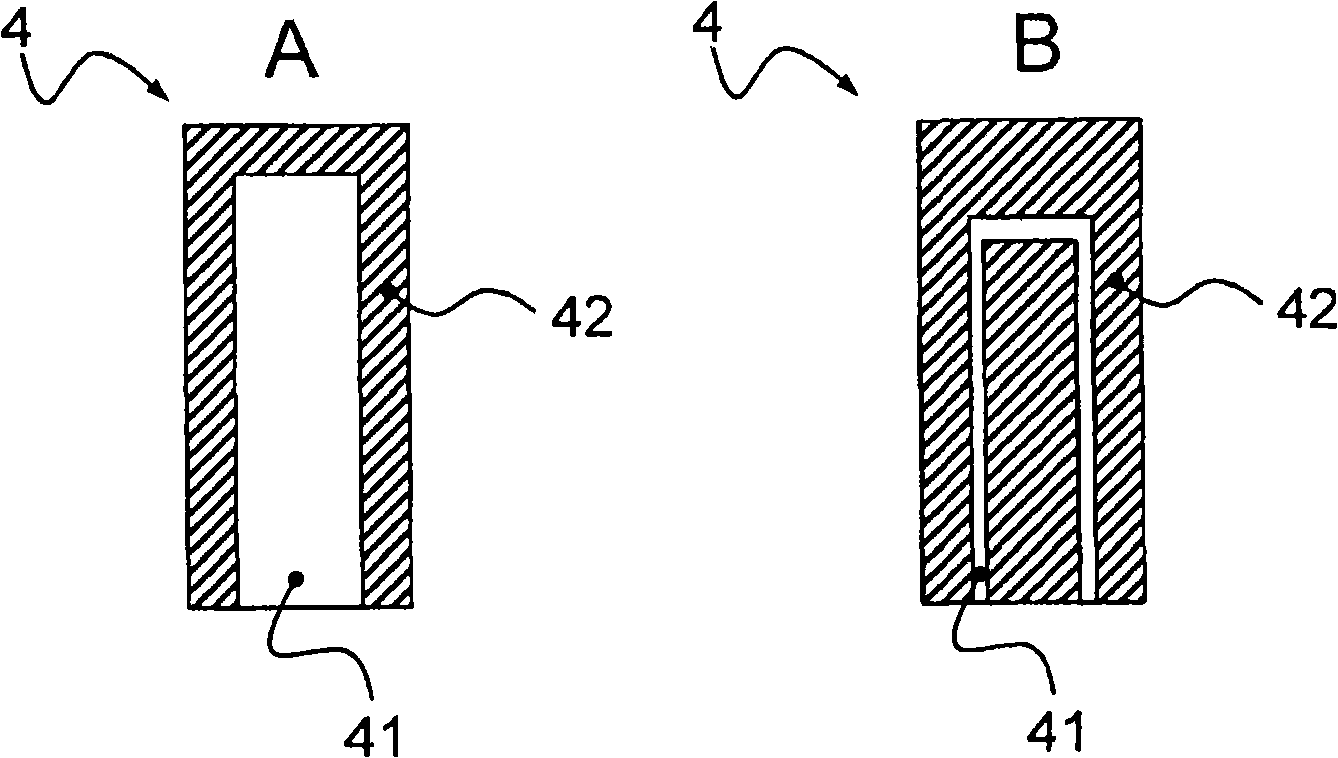

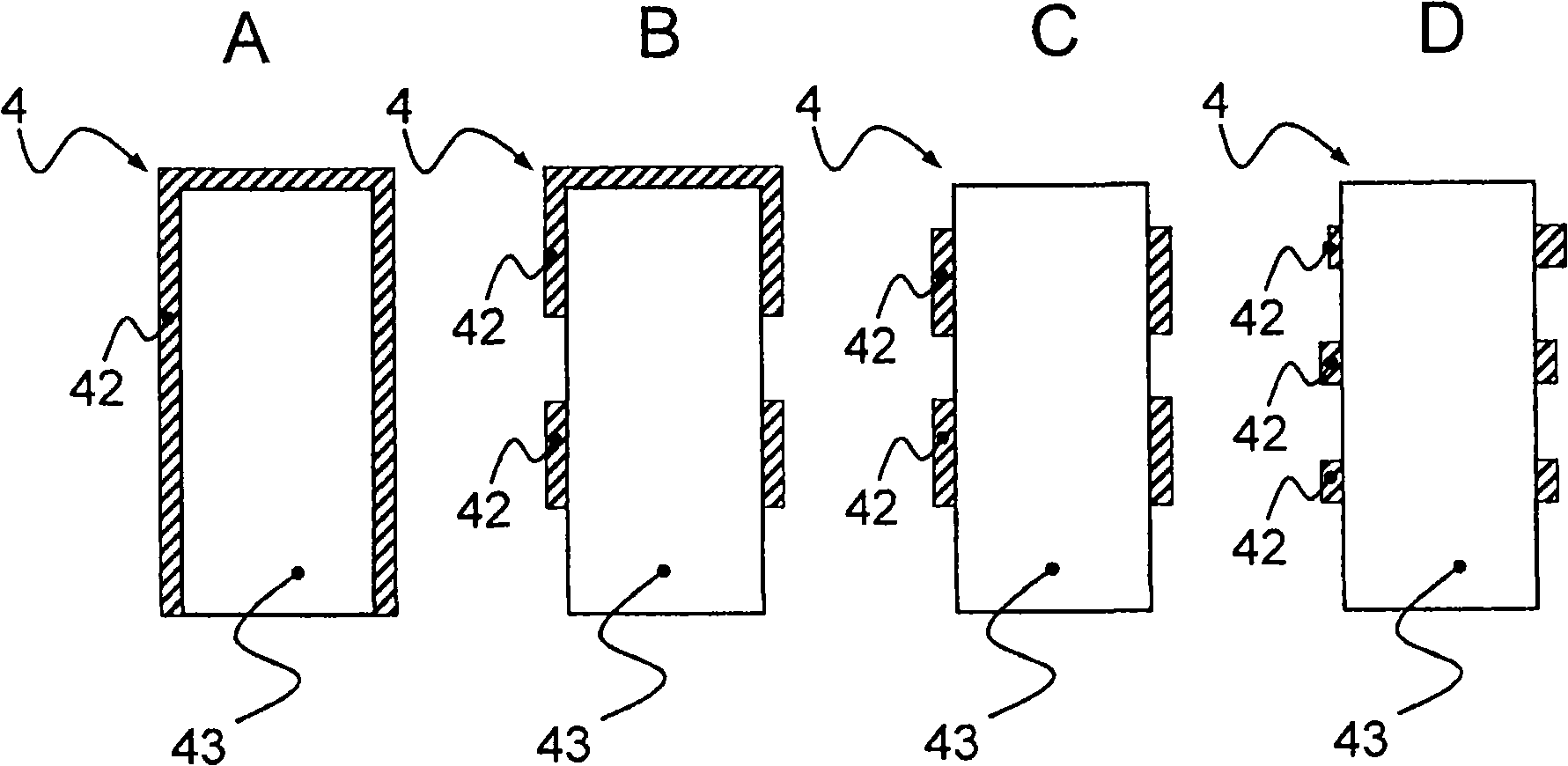

[0163] Regardless of the shape and geometry chosen for the electrodes 4 , the electrodes can have openings 41 inside them, through which a fluid for cooling the electrodes 4 can be piped. exist figure 2 In , an example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com