Betaine water-bearing liquid solution having solid content of at least 40% by weight

A betaine and solution technology, applied in the directions of dissolving and skin care preparations, cosmetics, etc., can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

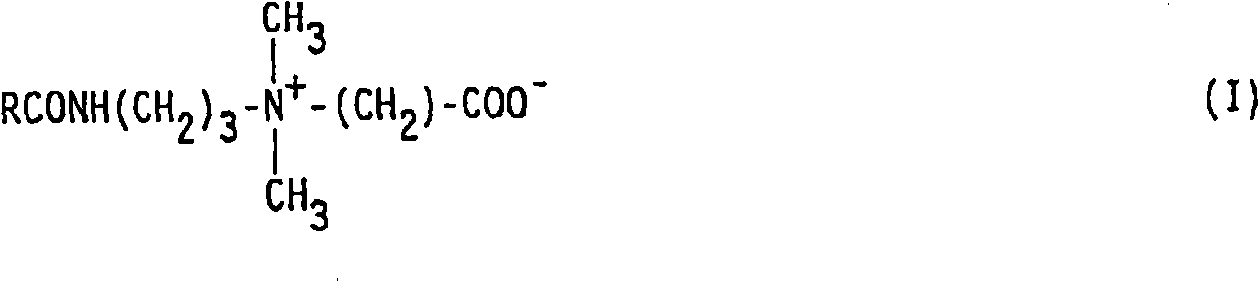

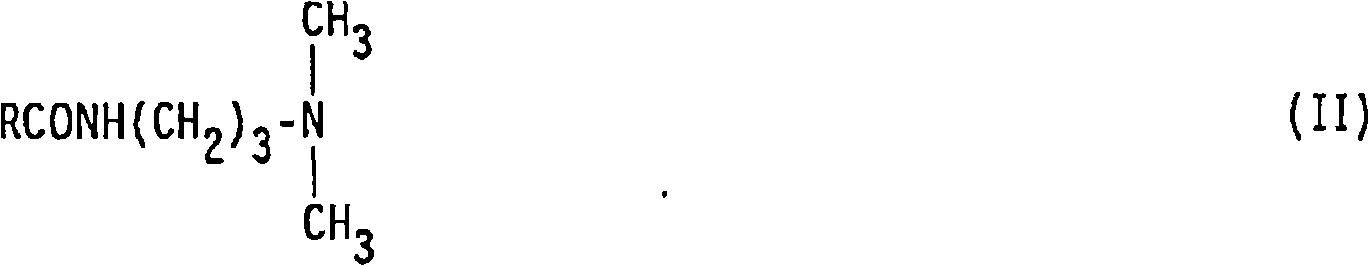

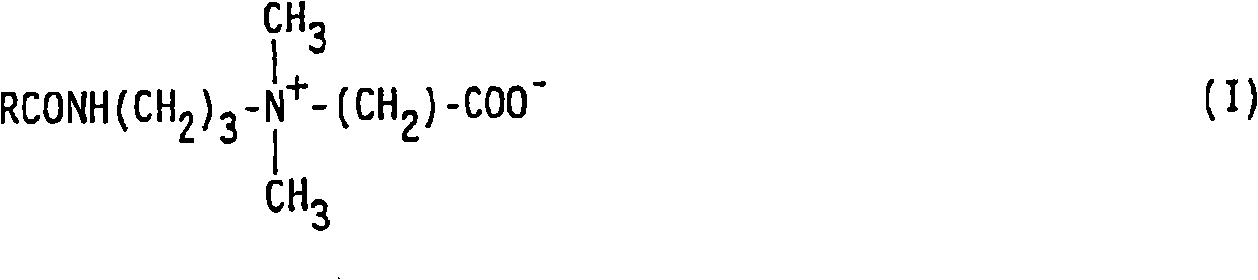

[0083] For the preparation of the betaine solution according to the invention, if an aminoamide of the formula II is used which already contains the required amount of free fatty acid, which in most cases is identical to the fatty acid RCOOH of the aminoamide. Thus, in the formulations used for the preparation of aminoamides, the content of free fatty acids can be taken into account. However, it is also possible to use an aminoamide having an acid value of 0 or about 0 and to add one or more saturated fatty acids having an average carbon number of 8 to 24 to the aminoamide.

[0084] If glycerin needs to be added, it can be added before or during the quaternization reaction. Although it is also possible to add glycerol after the quaternization reaction, this is not advantageous.

[0085] The betaine solution of the present invention achieves the goal of being free of external surfactants and having an aminoamide content of ≤ 1% by weight. In these regimens, it is not necessar...

Embodiment

[0088] In the following examples, coconut oil fatty acid aminoamides were prepared from, for example, various fatty materials and 3-N,N-dimethylaminopropylamine, and conventional commercial quality sodium monochloroacetate.

[0089] In Examples A1 to A4, betaine solutions not according to the invention were prepared. In Examples A1 and A2, the acid value was adjusted outside the required range, whereas in the inventive Examples B1 to B3, which were otherwise similar, a liquid state containing 45% solids was obtained. betaine solution. Glycerol was not present in Example A3, although it was necessary to obtain a flowable product. Except for this point, the inventive example B4, which is otherwise similar, illustrates this point. In the non-inventive example A4, the pH was not adjusted to 5-8.

[0090] The fatty acid aminoamides used are characterized by:

[0091] Fatty acid aminoamide A:

[0092] Tertiary amine nitrogen content: 4.6%

[0093] ...

Embodiment A1

[0184] Coconut fatty acid aminoamide A (305 g) was mixed with 1.1 g of coconut fatty acid with an acid value of 290. The resulting mixture of coconut oil fatty acid aminoamide and fatty acid had an acid value of 3; this corresponds to 0.36% fatty acid, calculated as lauric acid. This mixture was added to a solution of 131 g of 98% sodium monochloroacetate (1.1 moles) in 534 g of water and heated to 98°C with stirring. During the reaction, the pH was maintained between 8 and 9 by adding a few drops (about 1.5 mL) of 40% NaOH. The reaction stopped after 8 hours. The pH was adjusted to 6 with 10% aqueous hydrochloric acid before the temperature was lowered. Thereby, a gel-like non-flowing product is formed, which is characterized by the following values:

[0185] Solid content: 45%

[0186] Betaine: 37.2%

[0187] NaCl: 6.7%

[0188] Fatty acids: 0.1%

[0189] Glycerin: 0.97%

[0190] Aminoamide: <0.3%

[0191] pH: 6.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com