Betaine surfactant and preparation method and application thereof

A technology of surfactant and betaine, which is applied in the field of betaine-type surfactant and its preparation, can solve the problems of corrosion equipment, high economic cost, reservoir damage, etc., and achieve ultra-low interfacial tension, high yield and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The present embodiment provides a kind of betaine type surfactant, and it has following structure:

[0059]

[0060] Wherein, m=6, 7, 8 or 9, n=9, 8, 7 or 6, and m+n=15.

[0061] The above-mentioned betaine type surfactant provided in the present embodiment is prepared according to the following steps:

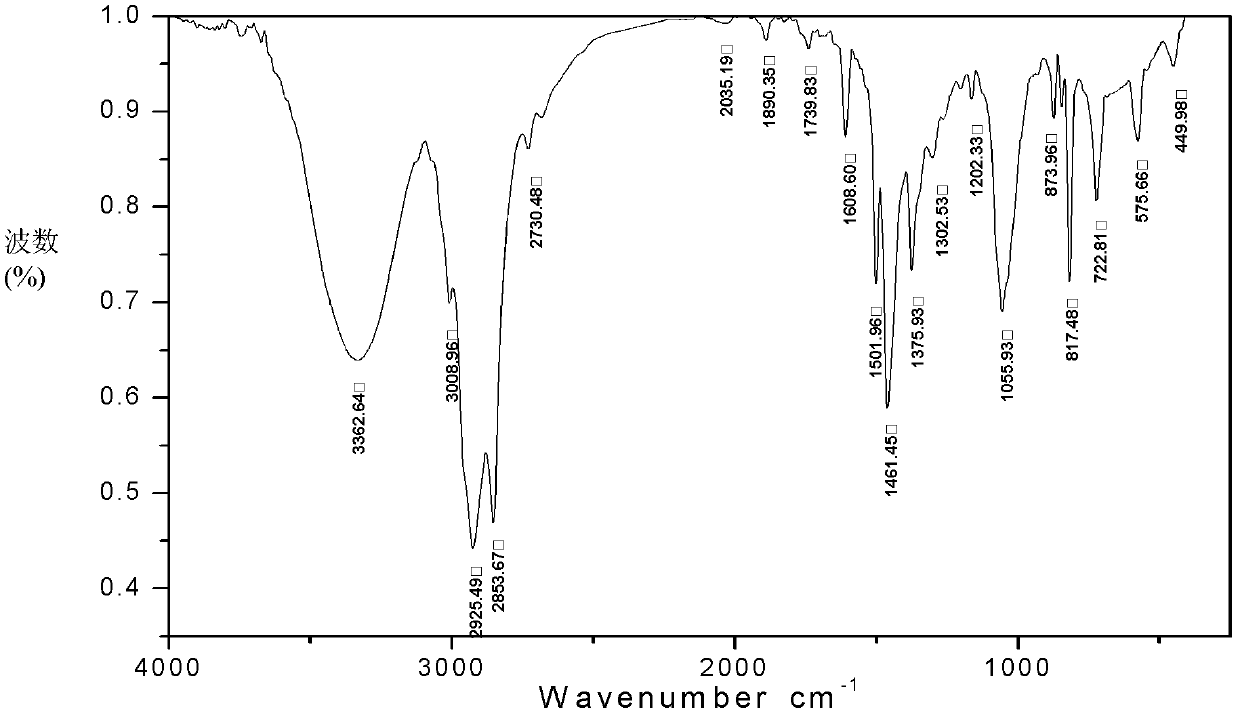

[0062] (1) Esterification reaction: Mix oleic acid and methanol (excess methanol), add concentrated sulfuric acid or p-toluenesulfonic acid as a catalyst, heat and reflux for 10 hours, cool, and then neutralize with sodium methoxide to a pH value of 8-9, use Wash with water until neutral, dry with anhydrous calcium chloride, and then distill under reduced pressure to obtain methyl oleate;

[0063] (2) Friedrich's alkylation reaction: In a sealed reaction kettle, add 3.5mol m-xylene and 0.75mol methanesulfonic acid, blow with nitrogen for 10min at room temperature, and then raise the temperature to 110-130°C under 0.15MPa , then dropwise add the methyl oleate that 1...

Embodiment 2

[0080] The present embodiment provides a kind of betaine type surfactant, and it has following structure:

[0081]

[0082] The above-mentioned betaine type surfactant provided in the present embodiment is prepared according to the following steps:

[0083] Step 1-4 is identical with embodiment 1;

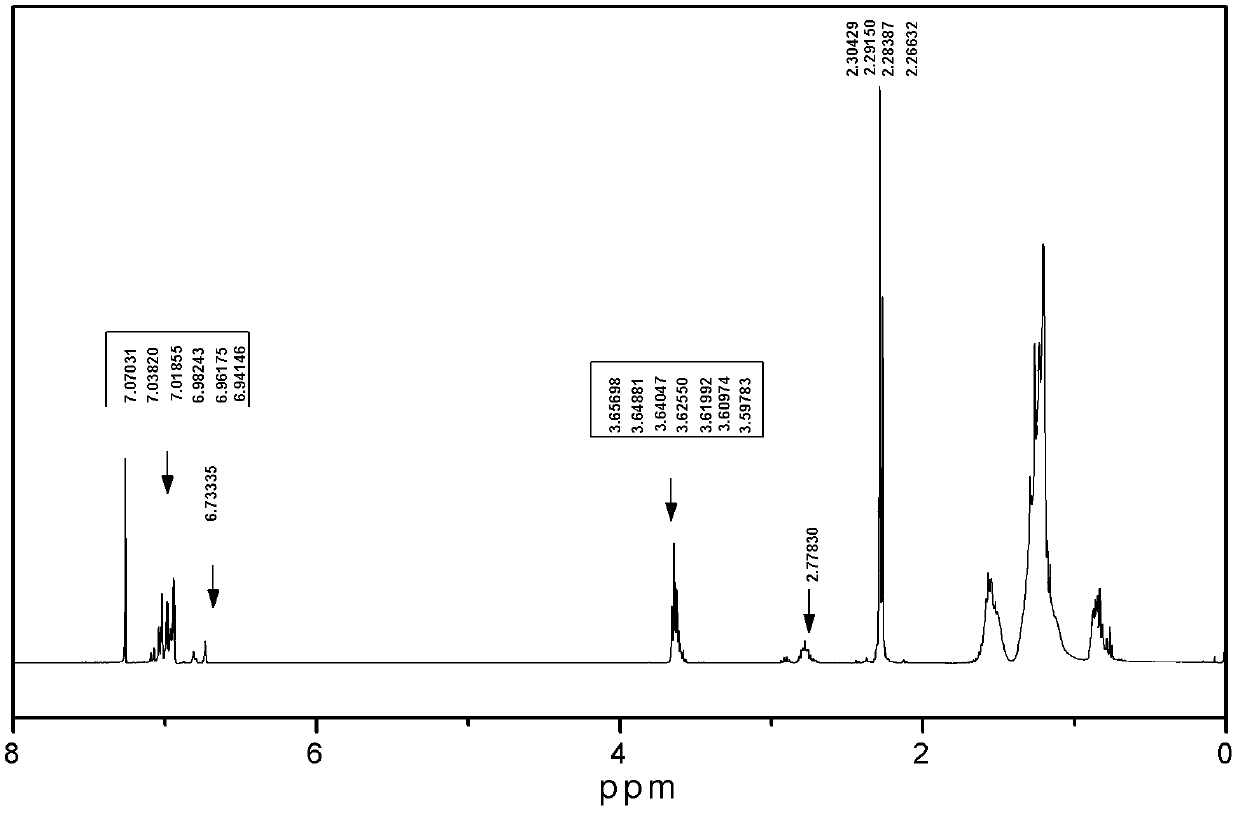

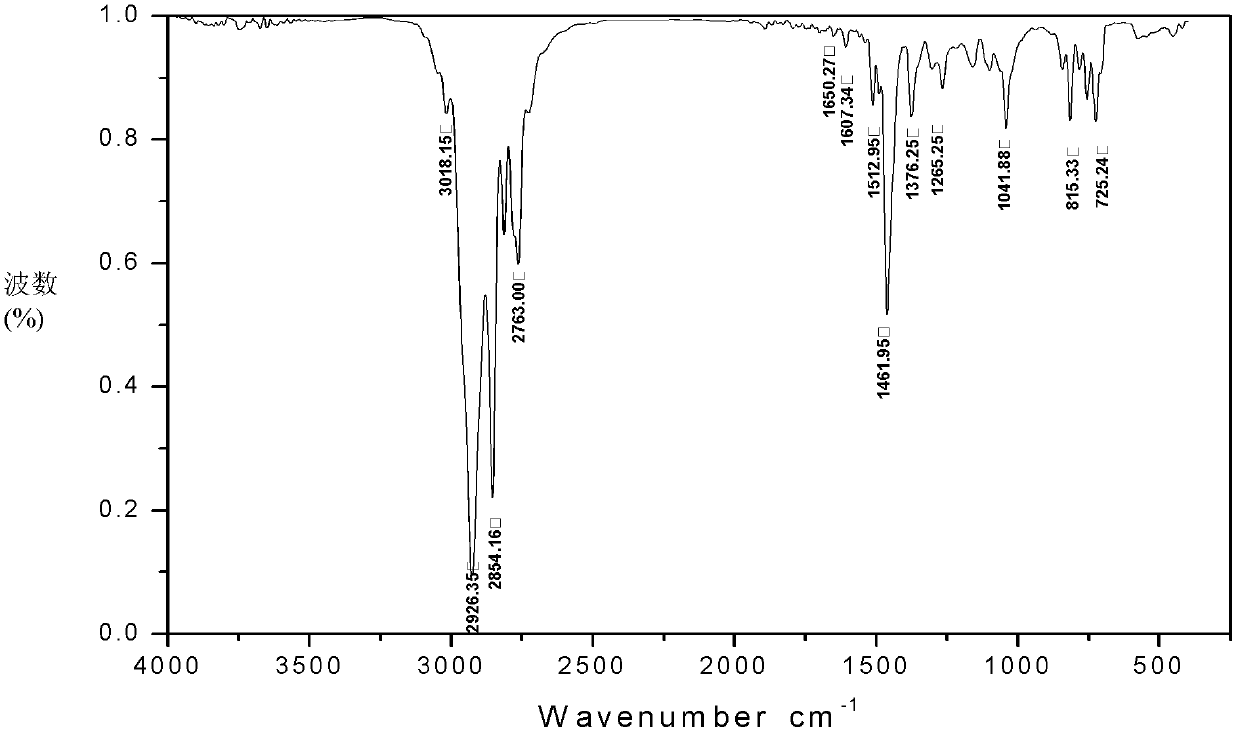

[0084] (5) Quaternization reaction: under the reaction conditions of 130°C and 0.3MPa, using methanol as a solvent, the reaction product of step (4) xylene α-octadecyl tertiary amine reacts with sodium chloroacetate to generate the target betaine type surfactant, its hydrogen spectrum is as follows Figure 7a As shown, the assignment of its hydrogen spectrum signal is as follows Figure 7b shown.

[0085] Industrial Applicability

experiment example

[0087] (1) Ultra-low interfacial tension experiment of binary system oil displacement agent

[0088] The target product of embodiment 2 is mixed with oil and water of Daqing No. 6 Plant to test its interfacial activity, and the test results are as follows: Figure 8 Shown, wherein, binary system is the binary aqueous solution of polymer and surfactant, and polymer is hydrophobic polyacrylamide, and molecular weight is 19 million, and concentration is 2000ppm, and surfactant is the betaine type surface that embodiment 1 provides active agent. The interfacial tension of the surfactant concentration in the binary system can reach ultra-low in the range of 0.05wt%-0.3wt%, which also shows that the synthesized betaine-type surfactant has excellent performance in kilogram samples.

[0089] (2) Ultra-low interfacial tension experiment of one-component system

[0090] The aryl alkyl betaine surfactant provided by the present invention has excellent ability and effect of reducing int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com