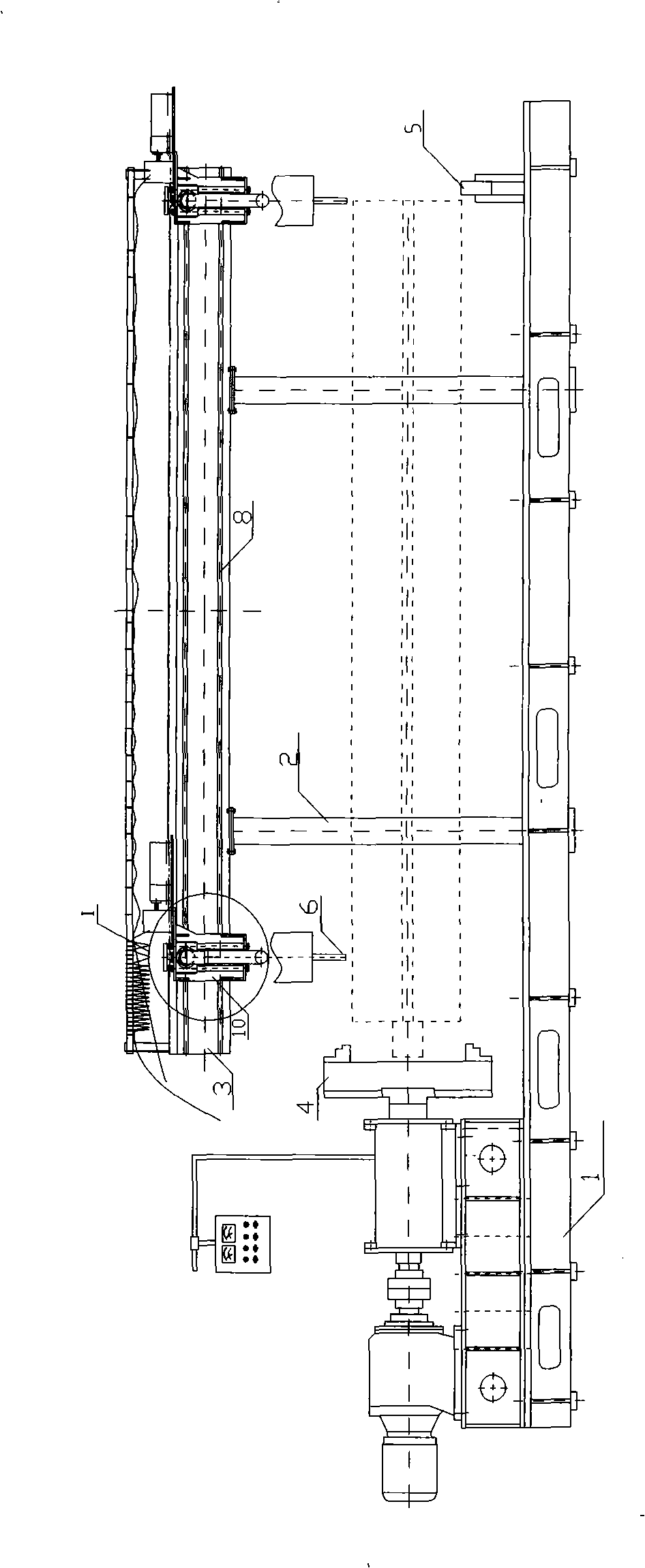

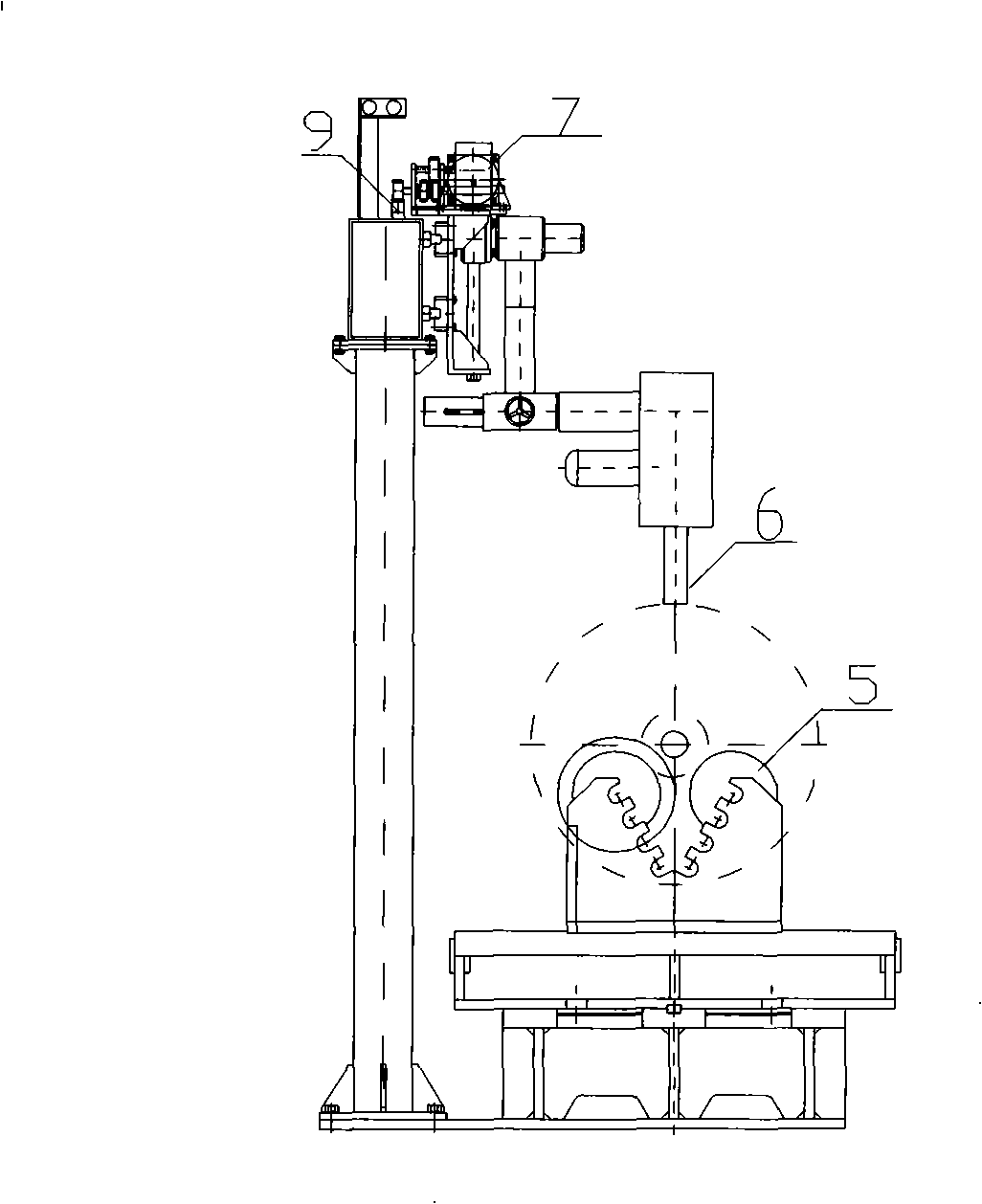

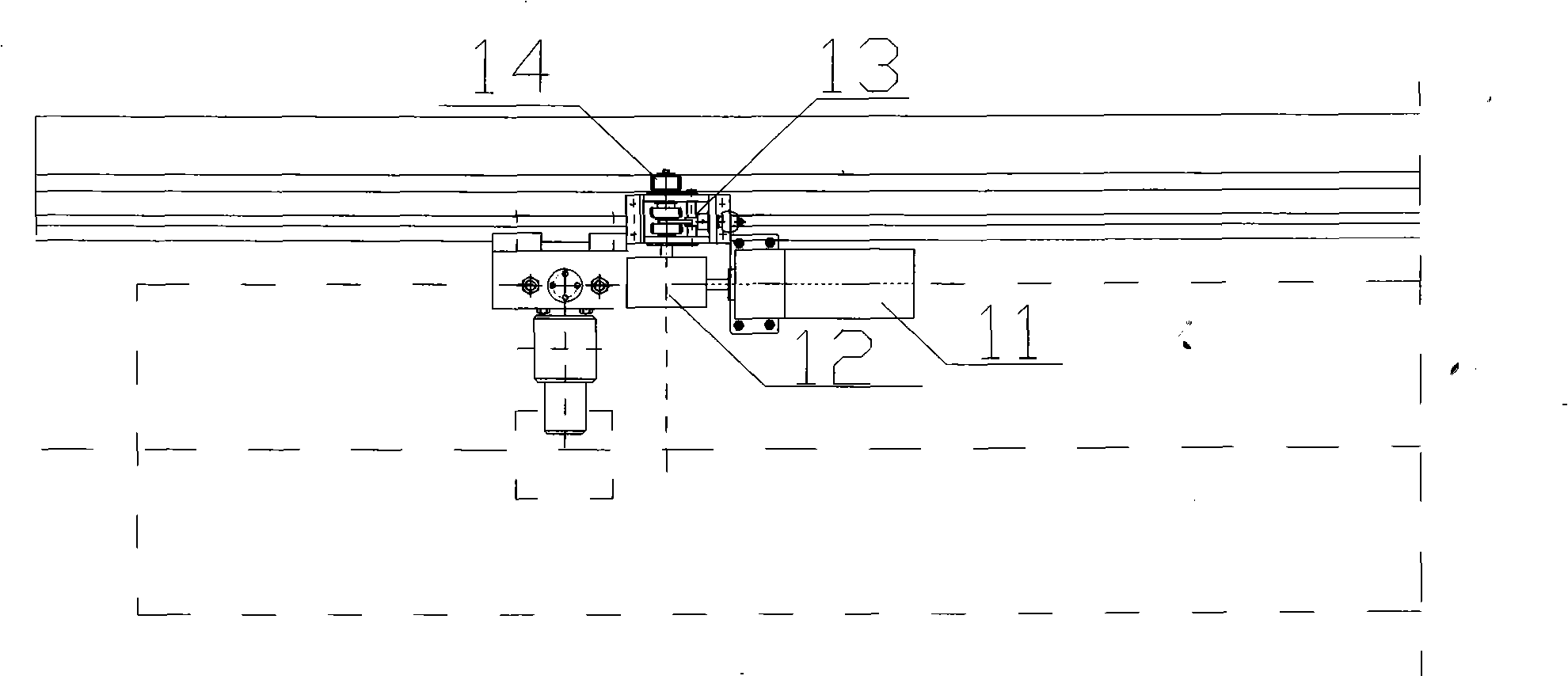

Double-handpiece column roller overlaying welding machine tool

A column-type, double-head technology, applied in the field of surfacing welding machine tools, can solve the problems of high heat source temperature, uneven weld bead width, small bed size, etc., achieve uniform weld width, improve surfacing welding quality, and machine The effect of smooth head walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Roller size: Φ350mm×3200mm; stainless steel surfacing is applied to the roller surface, and the hardness requirement is 52-56HRC. GY256 welding wire is selected, and the welding parameters are as follows:

[0021]

[0022] The double-head column-type surfacing welding machine tool and the original surfacing welding machine tool were respectively selected for surfacing welding. The welding parameters are exactly the same, and the original surfacing welding machine tool also uses two trolleys for operation.

[0023] The comparison results are as follows:

[0024] ① The working efficiency of the double-head column type surfacing machine is significantly higher than that of the original surfacing machine: the double-head column type surfacing machine takes 10.5 hours, and the original surfacing machine takes 12.25 hours. The original surfacing welding machine spent a lot of time dealing with slipping and jamming of the trolley.

[0025] ②The quality of the surfa...

example 2

[0029] Roller size: Φ500mm×2870mm; stainless steel surfacing is applied to the roller surface, and the hardness requirement is 42-48HRC. 0Cr13Ni4MoN welding wire is selected, and the welding parameters are as follows:

[0030] Current (A)

[0031] The surfacing welding is carried out on the double-head column type surfacing welding machine tool and the original surfacing welding machine tool respectively. The welding parameters are exactly the same, and the original machine tool also uses two trolleys for operation.

[0032] The comparison results are as follows:

[0033] 1. It took 22.5 hours for the double-head column type surfacing machine tool, and 28 hours for the original surfacing machine tool. With the prolongation of surfacing welding time, the probability of slipping and jamming of the surfacing welding trolley of the original surfacing welding machine increases.

[0034] 2. The quality of the surfacing rollers of the double head column type surfacing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com