Material for repairing lithium-based ceramic oral cavity and preparation thereof

A lithium-based technology for oral restoration, applied in dental preparations, pharmaceutical formulas, dental prostheses, etc., can solve the problems of high prices, achieve the effect of reducing material costs, reducing treatment costs, and good product repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

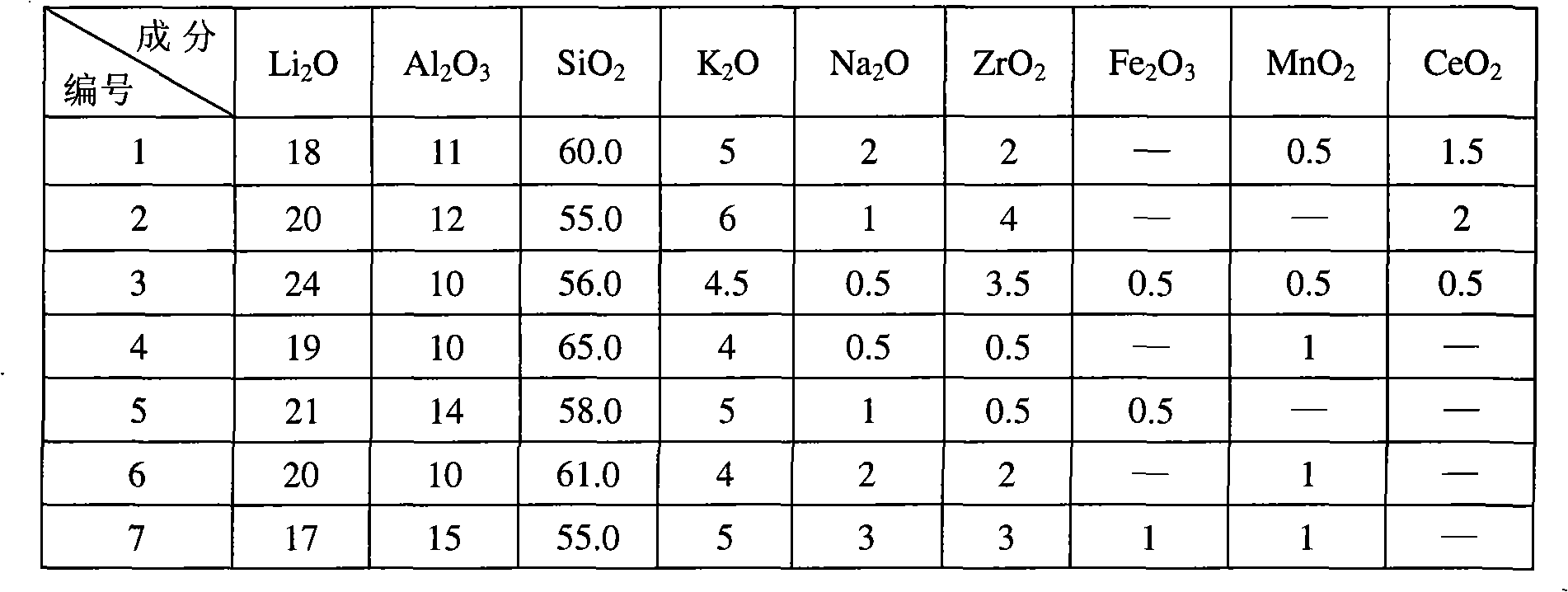

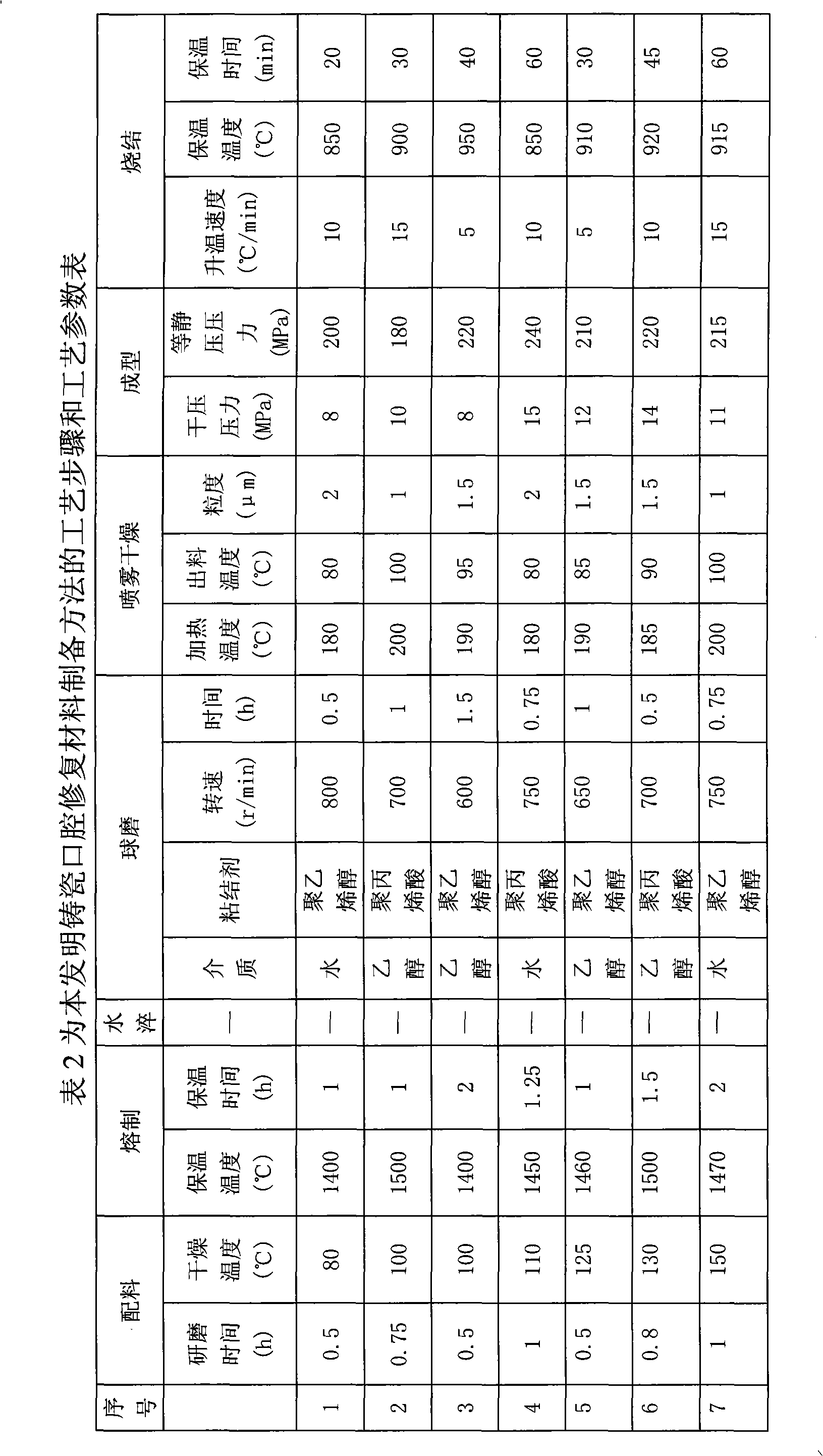

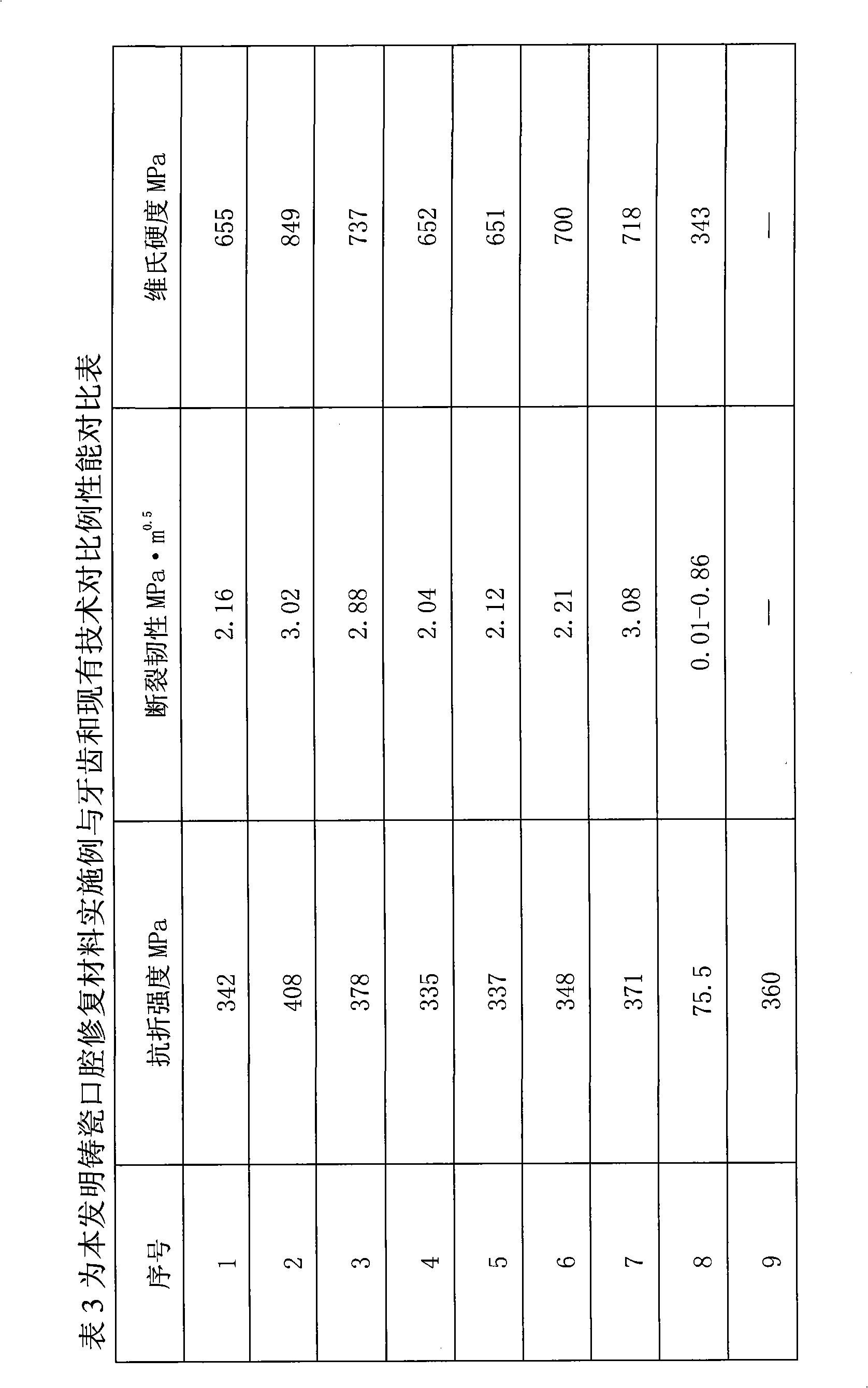

[0045] According to the chemical composition of the cast porcelain dental restorative material of the present invention, 4 batches of cast porcelain dental restorative materials were prepared by using the preparation method of the present invention. Wherein, Table 1 is the chemical composition table of the cast porcelain dental restorative material of the present invention, Table 2 is the process steps and process parameter table of the preparation method of the cast porcelain dental restorative material of the present invention, and Table 3 is the embodiment of the cast porcelain dental restorative material of the present invention Performance comparison table with teeth and prior art. Wherein, serial number 1-7# is the embodiment of the present invention, 8# is the performance of the tooth, and 9# is the performance of the casting porcelain product of Vita.

[0046] Table 1 is the chemical composition list (% by weight) of the cast porcelain dental restorative material of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com