ABO3 type perovskite composite oxides having high mixed conductivity

A composite oxide and conductivity technology, applied in the field of materials, can solve the problems of high preparation cost and complicated separation process of a single rare earth composite oxide, and achieve the effect of reducing preparation cost and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The material of the present invention can be synthesized by solid phase reaction method, glycine-nitrate method and sol-gel method. The synthesis method of the material of the present invention will be described below by taking the sol-gel synthesis as an example.

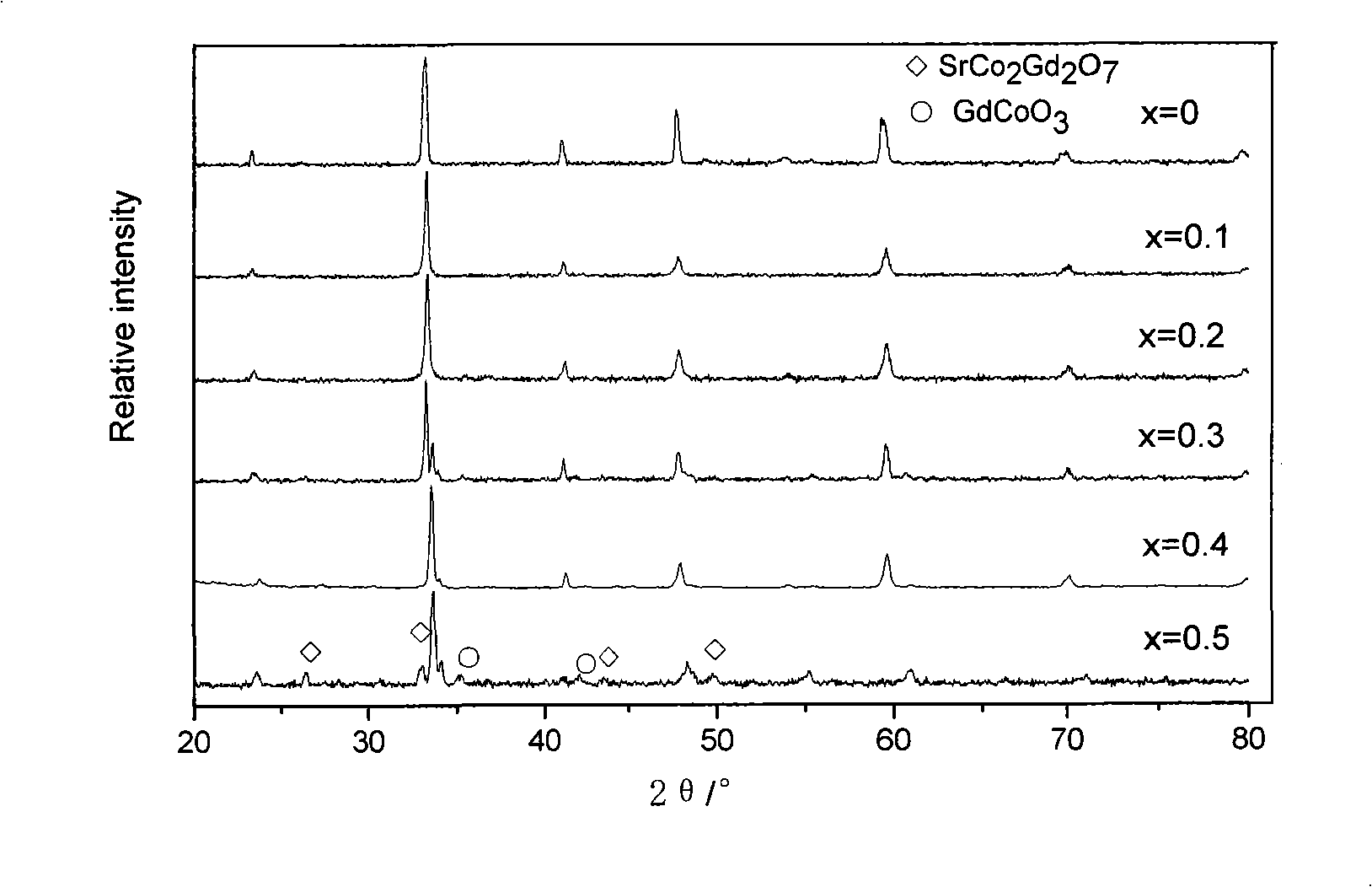

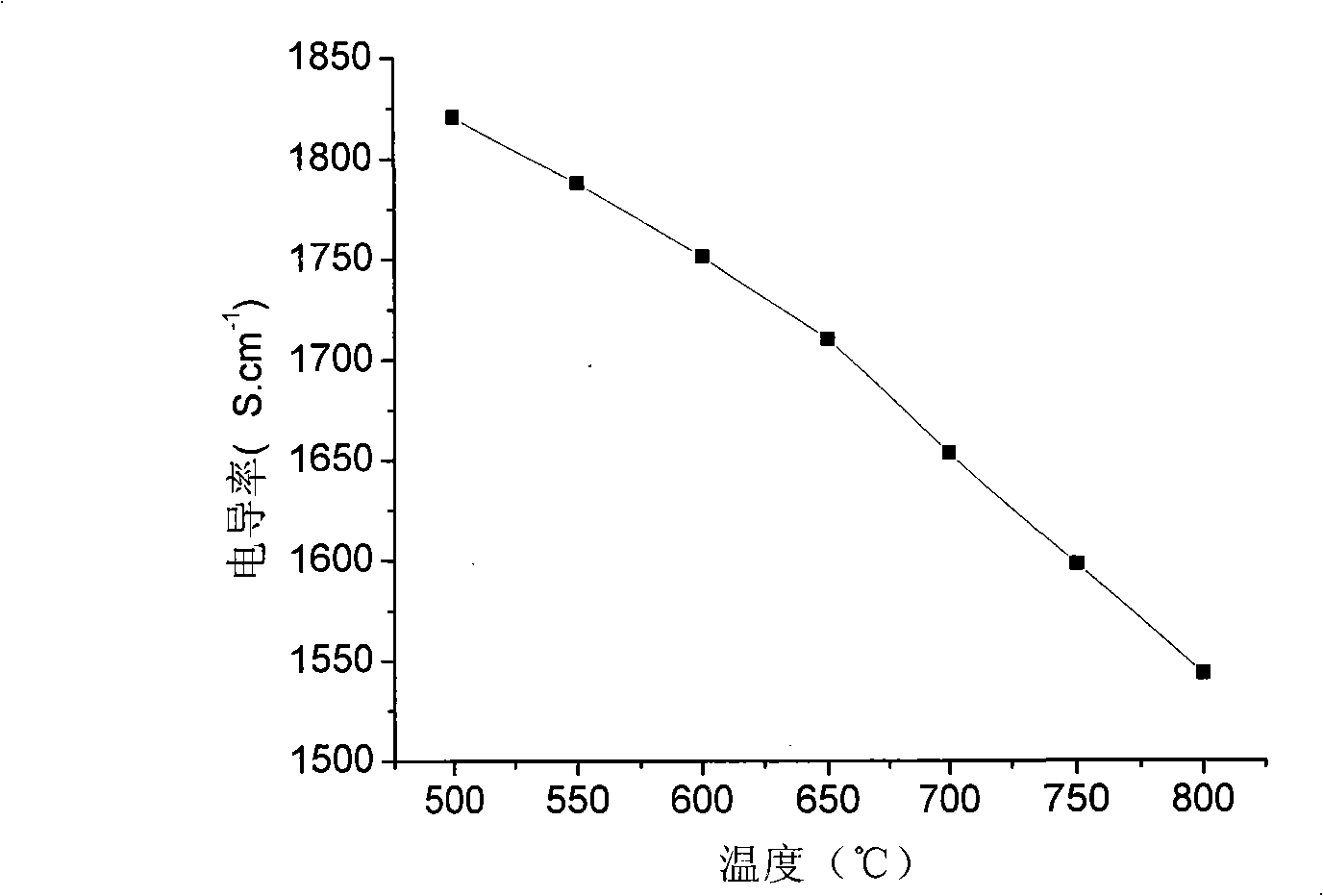

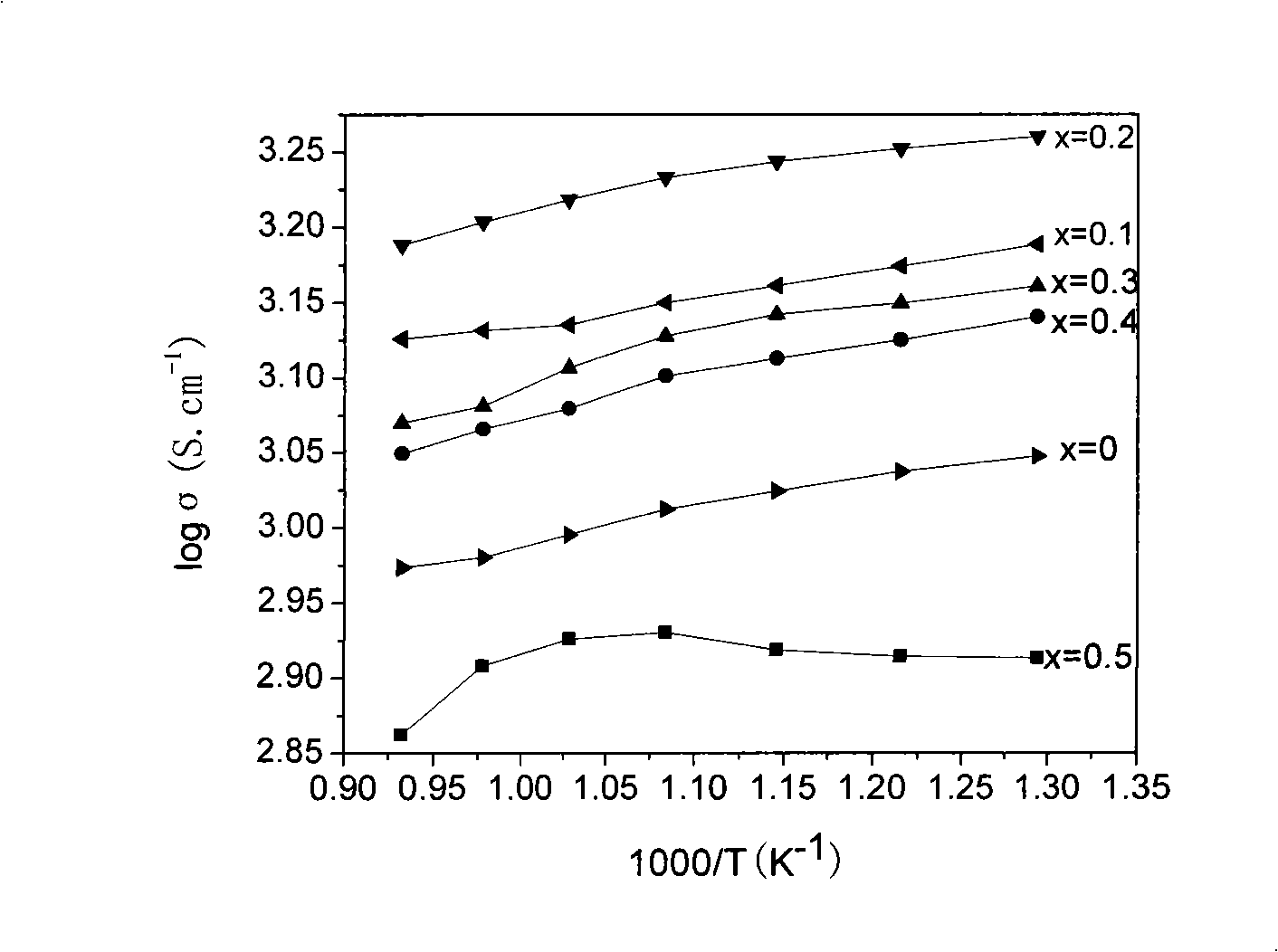

[0017] The chemical composition formula is Sm 0.5-x Gd x Sr 0.5 CoO 3-δ System oxide, wherein: 0<x<0.5.

[0018] There are 4 examples in the embodiment of the present invention. To synthesize 0.05mol of Sm 0.5-x Gd x Sr 0.5 CoO 3-δ For example, the required ingredients are shown in Table 1. The synthesis process is as follows:

[0019] 1. Weigh a certain amount of Sm according to the stoichiometric ratio 2 o 3 (chemically pure), Gd 2 o 3 (Chemical pure) add appropriate amount of distilled water, and add excess HNO 3 Make Sm 2 o 3 、Gd 2 o 3 Dissolve completely, then add 5.317g Sr(NO 3 ) 2 , 14.625g Co(NO 3 ) 2 ·6H 2 O, control the pH value of the mixed solution between 1 and 2.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com