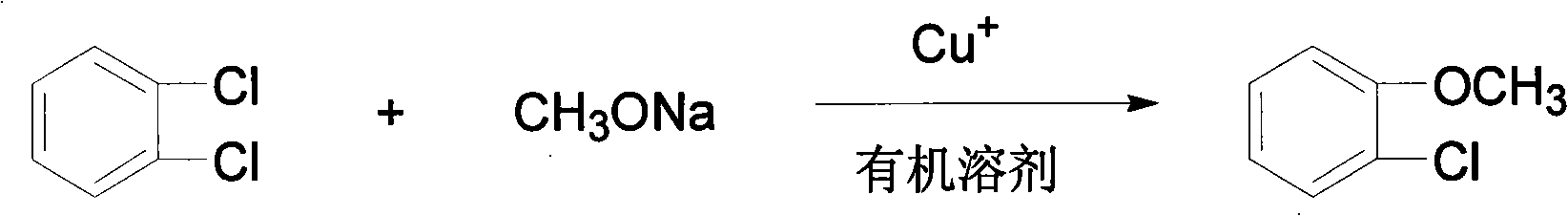

Process for synthesizing o-chloro-anisole

A synthesis method and chloroanisole technology are applied in the field of synthesis of fine chemical intermediates, can solve problems such as high price, difficult recycling, environmental pollution, etc., and achieve good industrial application prospects, high product yield, and environmental pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the reactor, o-dichlorobenzene (44.1g, 0.3mol), sodium methoxide solution (115.7g, 0.6mol) and N, N-dimethylformamide (100ml) with a mass fraction of 28% were mixed and added CuBr (3g, 0.021mol) was used as a catalyst, and the methanol was distilled under stirring until the kettle temperature reached 135°C and then refluxed for 20 hours; (30ml×3) extraction, and rectification of the organic liquid to obtain 32.2g of the compound o-chloroanisole, with a yield of 75.6%.

[0021] The experimental data are as follows:

[0022] b.p.193-195°C; 1 HNMR (400MHz, CDCl 3 )δ (ppm): 3.82 (s, 3H, OCH 3 ), 6.80-7.17 (m, 4H, ArH); IR (liquid film) cm -1 : 3057, 2999, 2965, 2940, 1583, 1549, 1462, 1300, 1253, 1134, 1026, 941; CI-MS: 142 (M + )

Embodiment 2

[0024] In the reactor, o-dichlorobenzene (58.8g, 0.4mol), a mass fraction of 28% sodium methoxide solution (38.6g, 0.2mol) and N,N-dimethylformamide (100ml) were mixed, and added CuBr (3g, 0.021mol) was used as a catalyst; the methanol was distilled under stirring until the temperature of the kettle reached 135°C and then refluxed for 20 hours; (30ml×3) extraction, and distillation of the organic liquid to obtain 8.1 g of the compound o-chloroanisole, with a yield of 28.5%.

Embodiment 3

[0026] According to the method in Example 1, the feeding amount of the sodium methoxide solution was 231.4 g, and 32.4 g of o-chloroanisole was obtained after the reaction, with a yield of 76.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com