Method for forming polysilicon film

一种多晶硅、非晶硅膜的技术,应用在气态化学镀覆、涂层、电气元件等方向,能够解决很难满足微细加工等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, in the following description, components having substantially the same function and structure are denoted by the same reference numerals, and descriptions are repeated only when necessary.

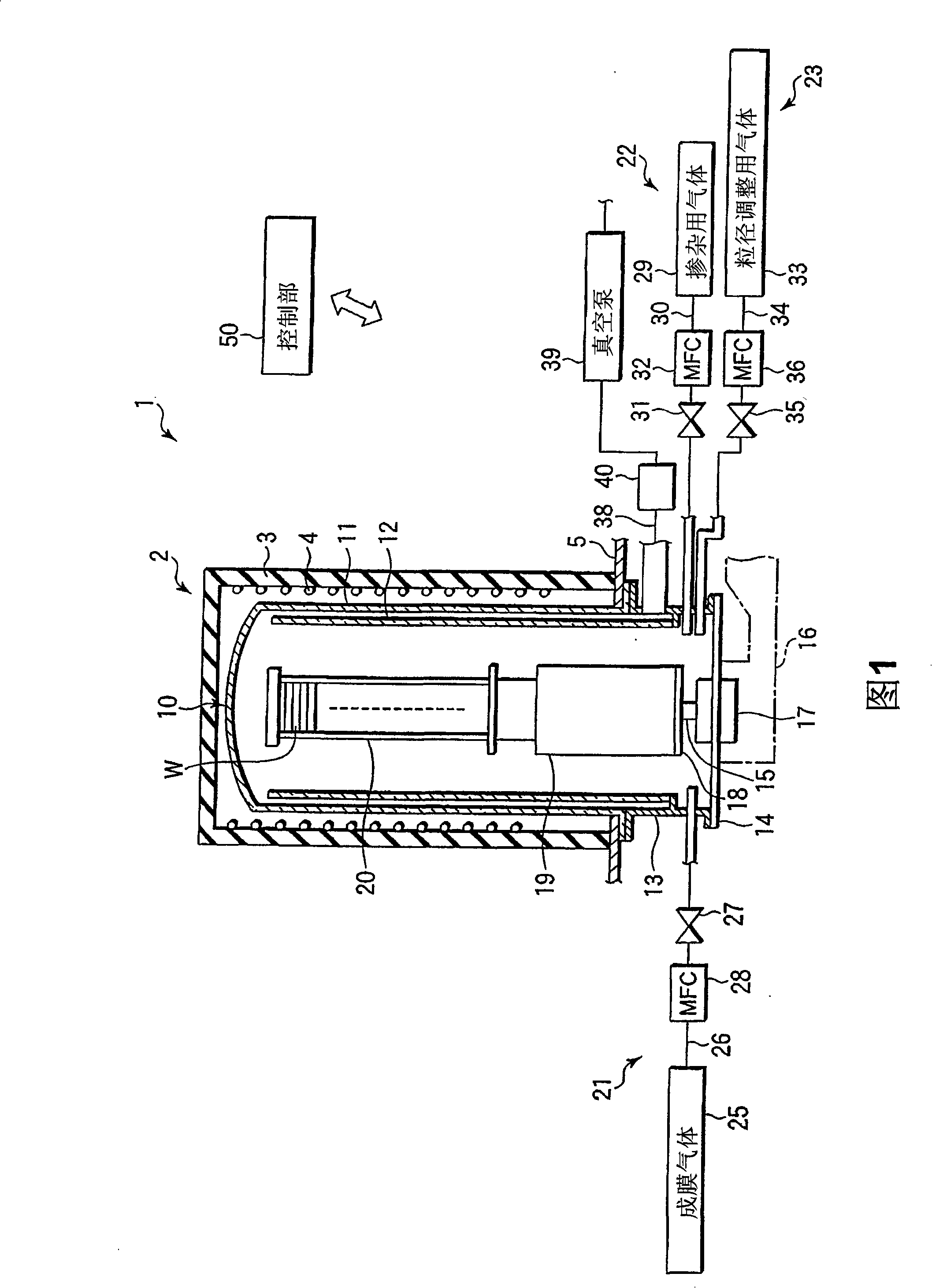

[0023] FIG. 1 is a longitudinal sectional view of an example of a film forming apparatus for carrying out a film forming method according to an embodiment of the present invention. The film forming apparatus 1 has a heating furnace 2 including: a cylindrical heat insulator 3 having a top; and a heater 4 provided on the inner peripheral surface of the heat insulator 3 . The heating furnace 2 is arranged on a base 5 .

[0024] Inserted in the heating furnace 2 is a reaction tube 10 as a reaction vessel. The reaction tube 10 is formed to have an outer tube 11 made of, for example, quartz and whose upper end is closed, and an inner tube made of, for example, quartz which is conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com