Drive circuit for laser

A technology for driving circuits and lasers, used in lasers, laser parts, semiconductor lasers, etc., can solve the problems of laser wavelength drift, overshoot, and system work confusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

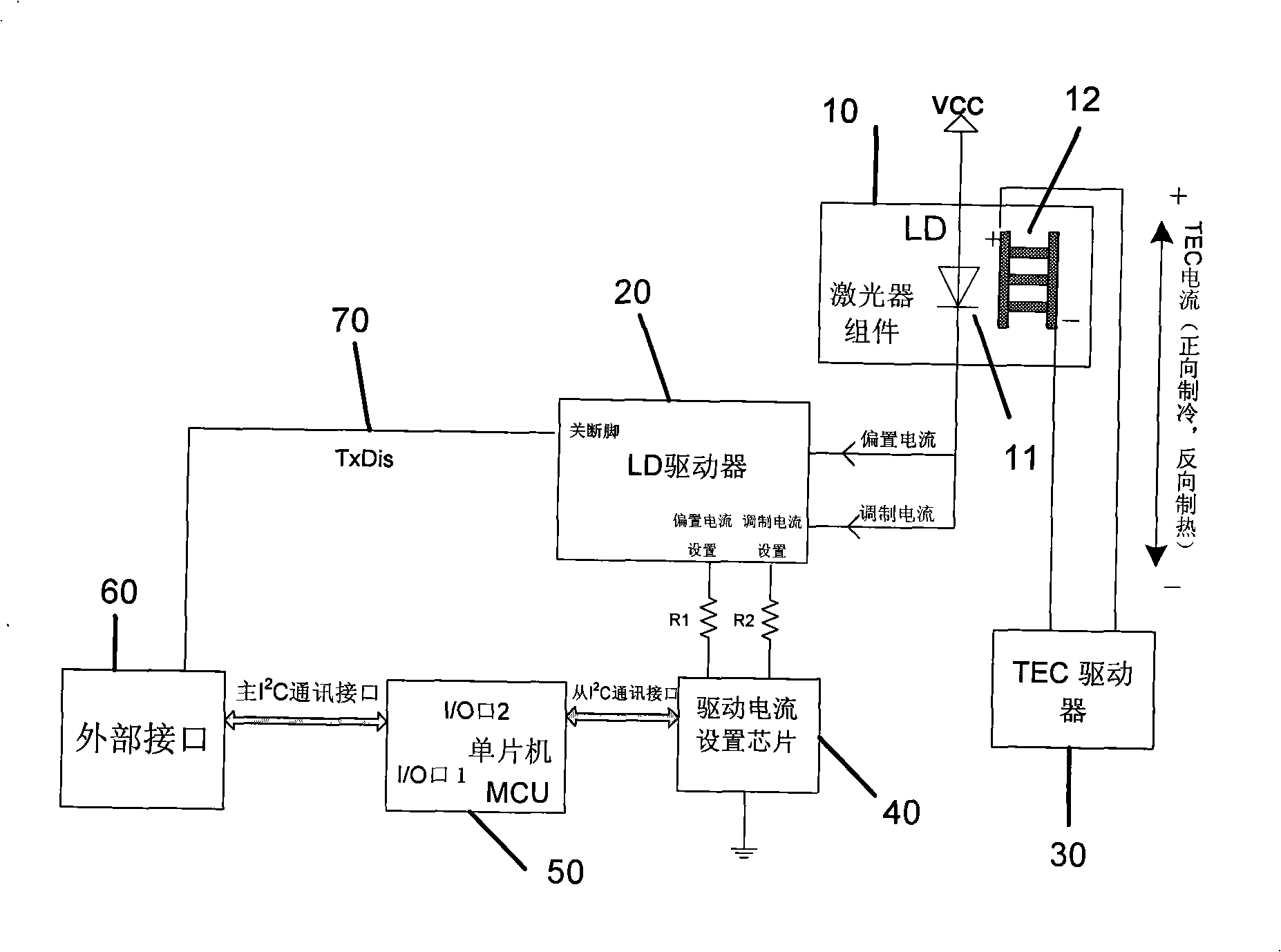

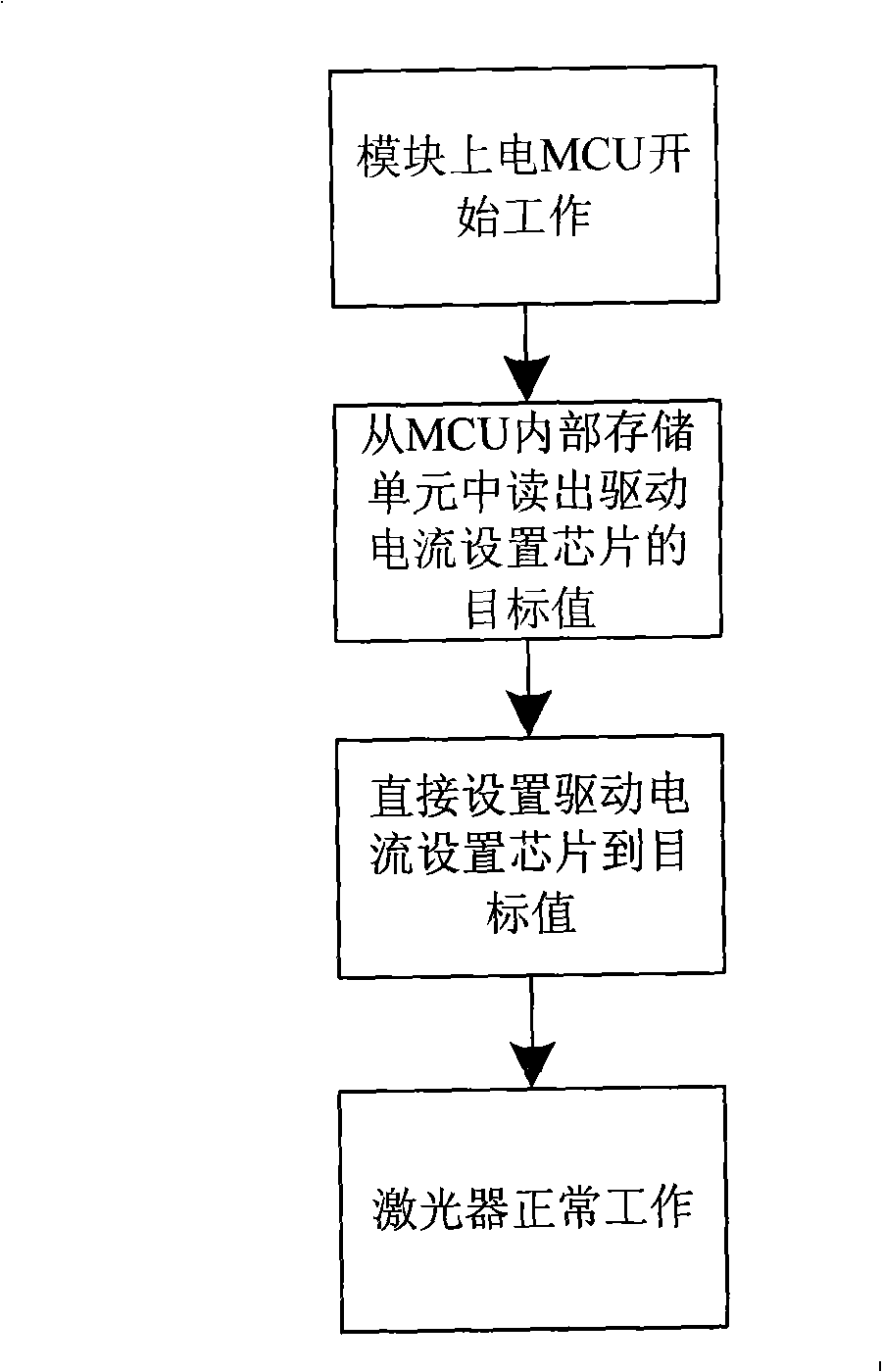

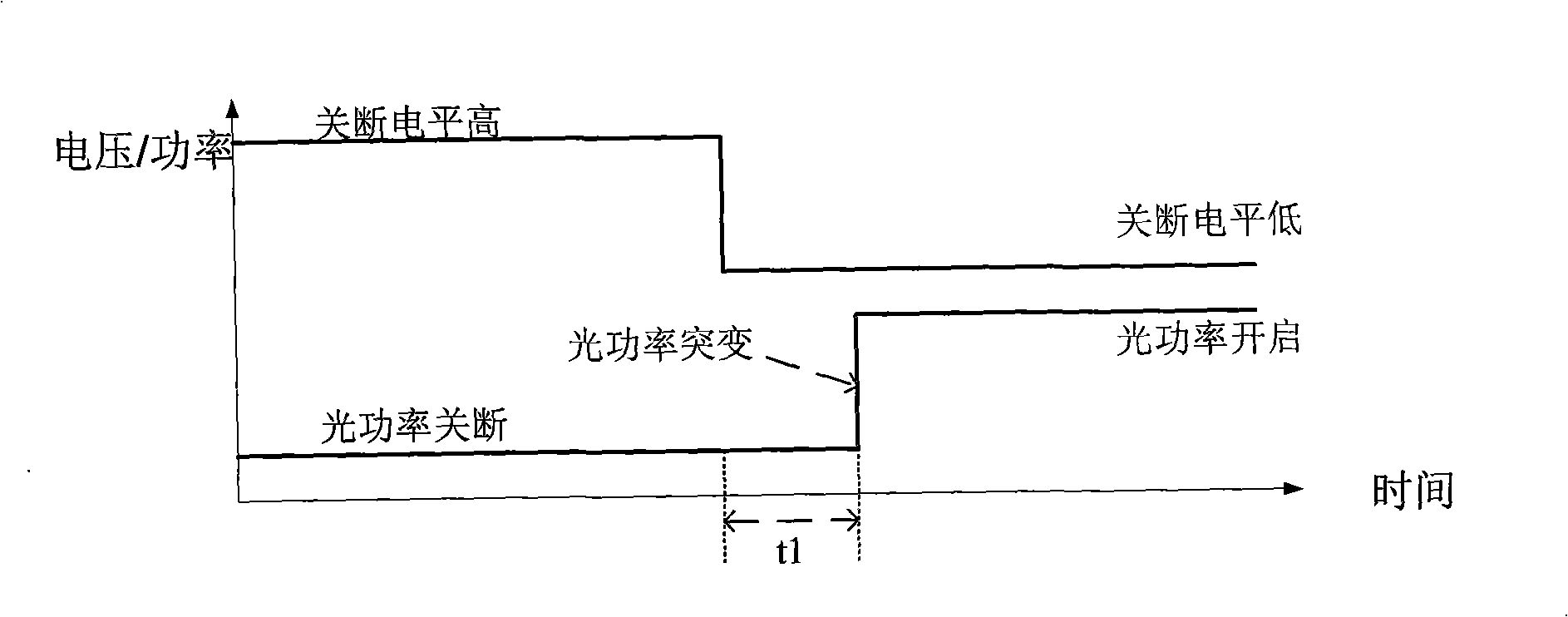

[0016] like Figure 4 The shown laser driving circuit includes a laser assembly 100, which is integrated by a laser diode LD110 and a thermoelectric cooler TEC120, the anode of the laser diode LD110 is connected to the power supply Vcc, and the cathode is connected to an LD driver 200 as the bias current and The modulation current conduction path, the thermoelectric cooler TEC120 is connected to a TEC driver chip 300, and the bias current setting terminal and the modulation current setting terminal of the LD driver 200 are connected to a driving current setting chip 400, wherein the driving current setting chip 400 can be Digital-to-analog conversion chip DAC or digital potentiometer. The drive current sets the chip 400 through the slave I 2 The C communication interface or other bus interface is connected with a single chip MCU500, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com