Composite graphite for lithium secondary battery and manufacturing method thereof

A lithium secondary battery and composite graphite technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as peeling off of coated carbon materials, material deformation, and excessive specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further have a deeper layer on the structure, use and characteristics of the present invention, clearly,

[0025] Detailed knowledge and understanding, give preferred embodiment, cooperate drawing to describe in detail as follows:

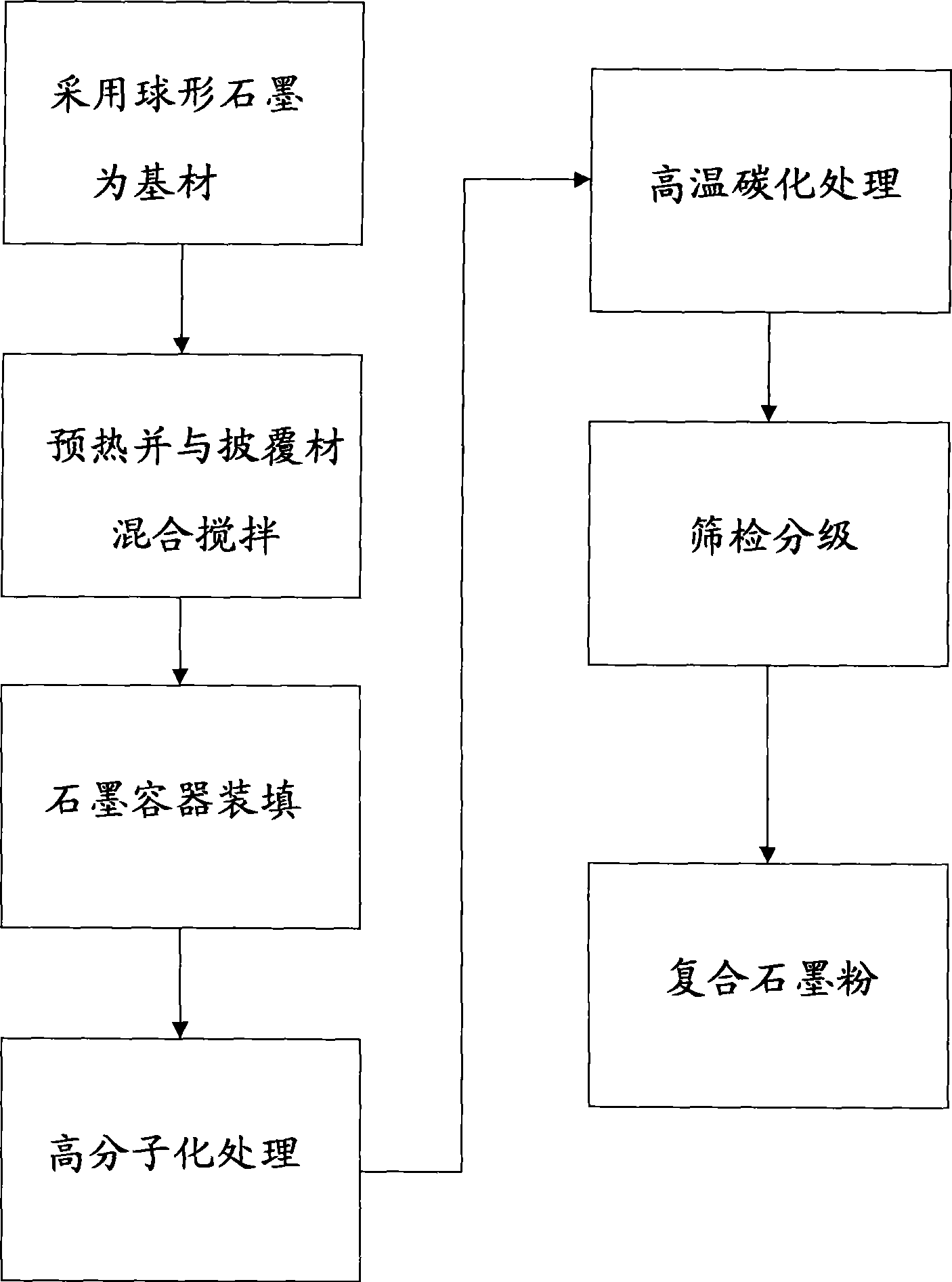

[0026] See first figure 1 Shown, the present invention is a kind of composite graphite for lithium secondary battery and manufacturing method thereof, and it comprises following manufacturing steps:

[0027] First select the fixed carbon fixed carbon ≥ 99.9%, the interval of crystal layer is d 002 High-purity spherical graphite of ≤0.337nm is used as the substrate, preheated to the preset temperature with a heating kneader, put the coating material into the substrate, and stir and mix, then put the above mixture into the graphite container, Send the mixture into a hot air constant temperature circulation furnace to polymerize the mixture. The internal roasting conditions of the above hot air constant temperature circulation fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com